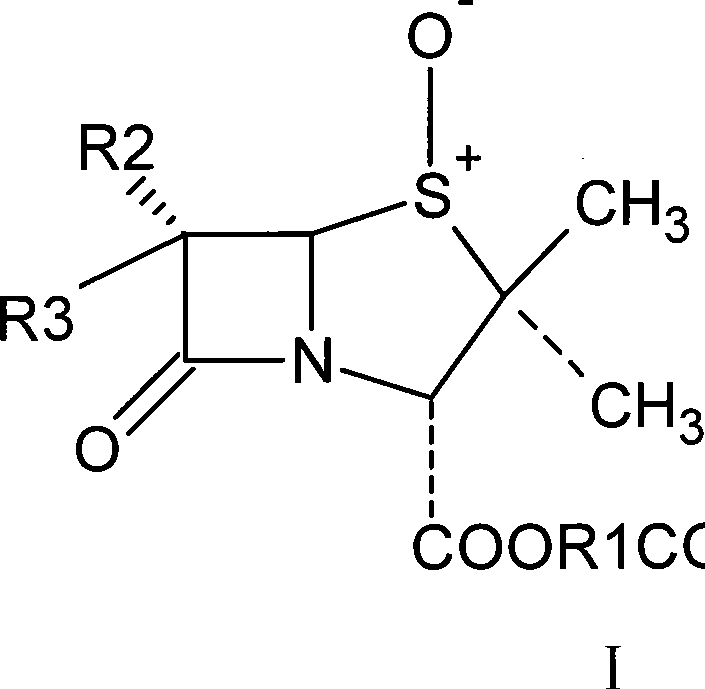

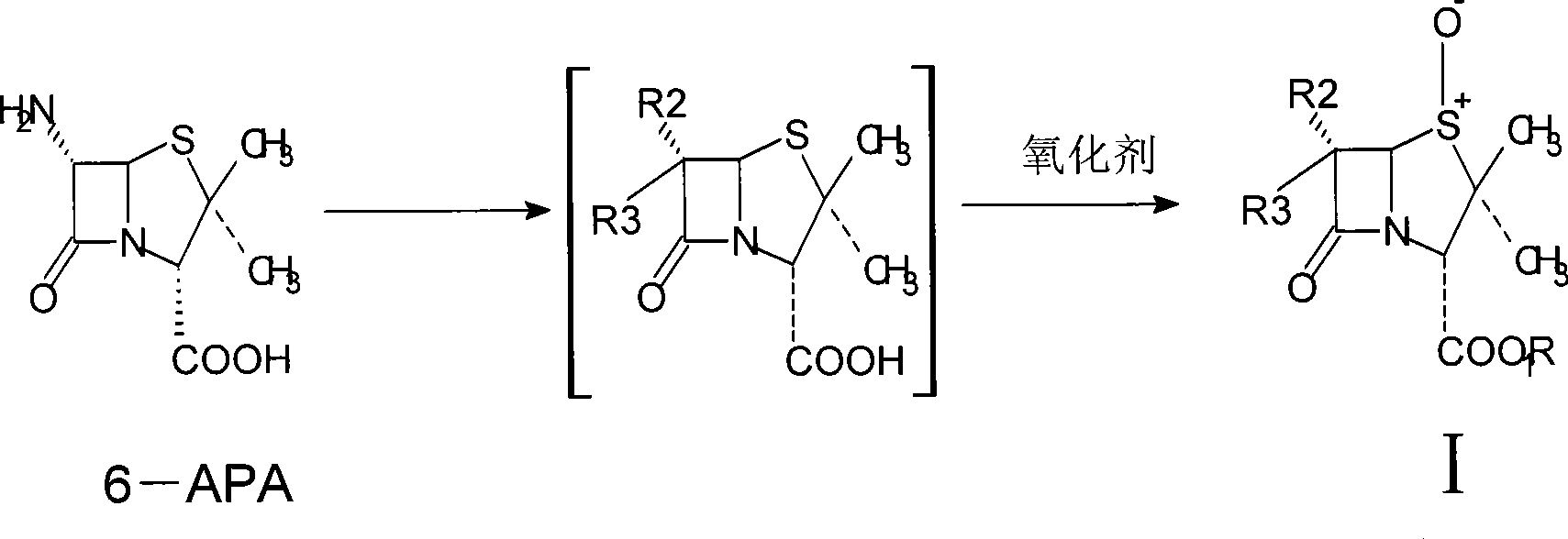

Catalytic oxidation system and use thereof in tazobactam synthesis

A catalytic oxidation and system technology, applied in the field of chemistry, can solve the problems of high price of hexafluoroisopropanol, difficult recovery and high volatility, and achieve the effects of high utilization rate, good reaction selectivity and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1. Preparation of catalytic oxidation system

[0034] Catalytic oxidation system of sodium tungstate, hydrochloric acid and hydrogen peroxide

[0035] Sodium tungstate and 30% hydrogen peroxide were mixed at a mass ratio of 1.5:100, stirred for 5-10 minutes, and the pH was adjusted to 2.0 with about 1ml of 16% hydrochloric acid. At this point the color of the solution is pale yellow or just disappears.

Embodiment 2

[0036] Embodiment 2. Preparation of catalytic oxidation system

[0037] Catalytic Oxidation System of Sodium Tungstate, Oxalic Acid and Hydrogen Peroxide

[0038] Sodium tungstate, oxalic acid, and 30% hydrogen peroxide were mixed in a mass ratio of 2.0:3.3:350, and stirred vigorously for 15 minutes.

Embodiment 320

[0039] Preparation of the ultrastable Y-type zeolite catalyst of embodiment 3.20% loading sodium tungstate

[0040] Accurately weigh 10g of sodium tungstate and dissolve it in 100ml of ethanol water solution (volume ratio of ethanol / water is 1 / 1), stir until dissolved, add 50g of ultra-stable Y-type zeolite with particle size above 200 mesh, and stir at room temperature for a long time Make the wetting balance, then evaporate the obtained suspension to dryness, dry it at room temperature, and then dry it at 120°C for 24 hours to obtain an ultrastable Y-type zeolite catalyst loaded with sodium tungstate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com