Method and apparatus for refining D-glucuronolactone

A technology of glucuronolactone and refining method, which is applied in the direction of chemical instruments and methods, sugar compounds with non-glycosyl groups, sugar derivatives, etc., can solve the problems of consuming large filter paper, manpower and filter paper, and color point exceeding the standard, etc. Achieve the effects of easy scale, low filtration cost and labor saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

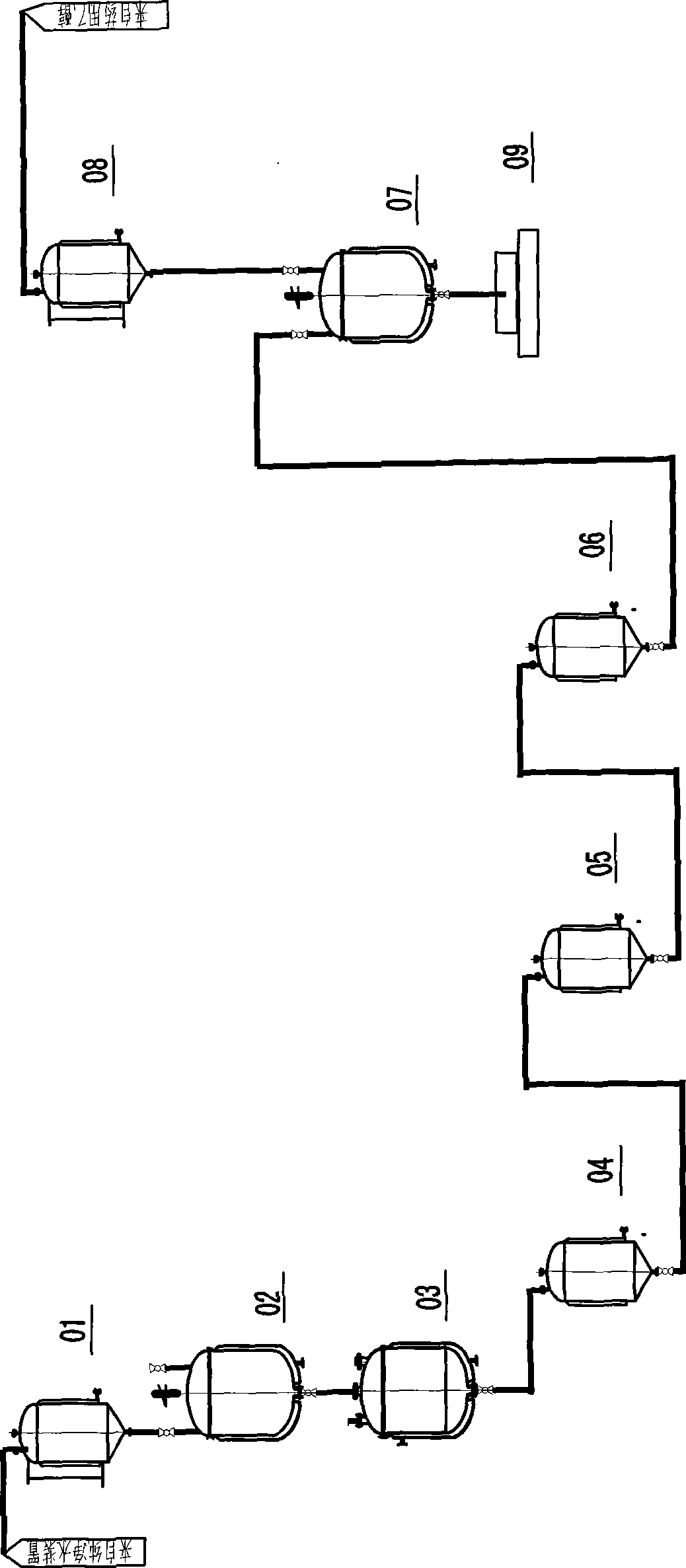

Image

Examples

Embodiment 1

[0023] a. Add 800L of pure water to the 2000L dissolution kettle;

[0024] b. Use steam to heat the pure water to 85°C and start feeding 1000KG of crude glucuronolactone. After adding 10KG of activated carbon, control the temperature at about 80°C, stir and keep warm for 10 minutes to fully dissolve;

[0025] c. After the heat preservation is over, put the feed liquid into a 2000L pressure filter tank, and pressurize it with clean air to make the feed liquid pass through the stainless steel plate mesh filter, the stainless steel filter cloth filter and the 0.01-0.5 micron membrane filter into the 2000L crystallization tank ;

[0026] d. Add 200KG of medicinal ethanol from the ethanol metering tank to the crystallization kettle to cool down to -5--8°C to crystallize, put the crystallization liquid into a centrifuge for dehydration, wash, and dry under reduced pressure to obtain 800KG of finished glucuronolactone.

[0027] The following table is four embodiments provided, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com