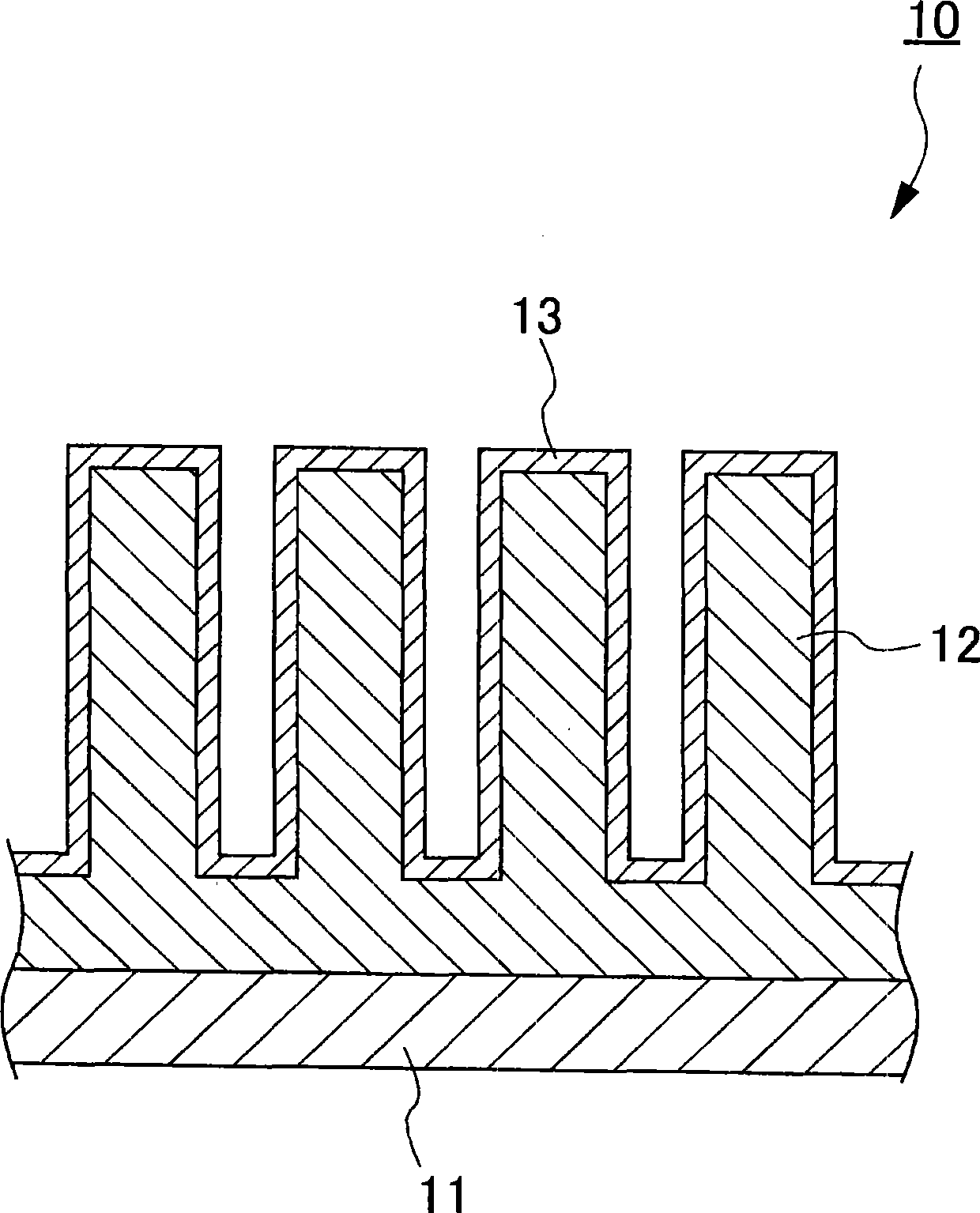

Cathode substrate

A technology of substrate and negative electrode, which is applied in the direction of electrode manufacturing, battery electrodes, active material electrodes, etc., can solve the problems of poor adhesion between the negative electrode material layer and the current collector, and the inability to obtain charge-discharge cycle characteristics, etc., to achieve charge-discharge The effects of excellent cycle characteristics, high energy density, and high output voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

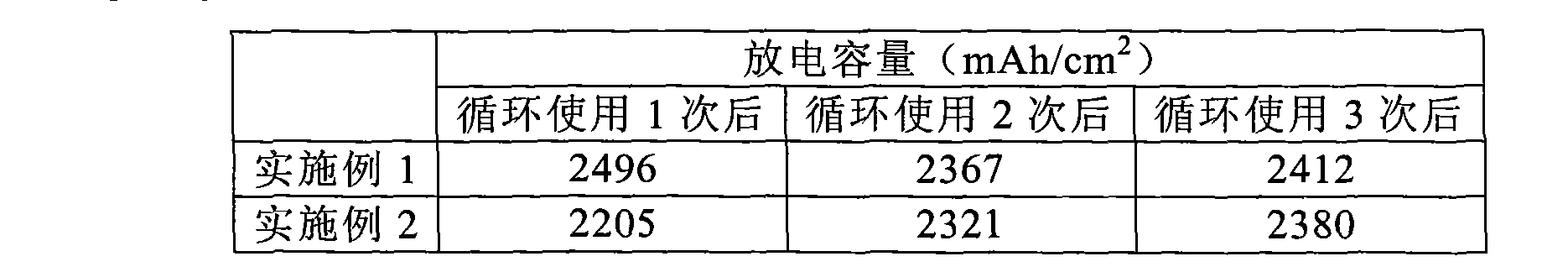

Examples

Embodiment 1

[0086] 100 parts by mass of multifunctional bisphenol A novolac epoxy resin "Epikote 157S70 (trade name, manufactured by Japan Epoxy Resin Co., Ltd.)", 5 parts by mass of diphenyl [4-(phenylthio) phenyl] A mixture of sulfonium hexafluorophosphate and thiobis-p-phenylene bis(diphenylsulfonium)bis(hexafluorophosphate) "UVI-6992 (trade name, manufactured by Dow Chemical Company)", 5 parts by mass of 1, A negative photoresist composition was prepared by mixing 5-dihydroxynaphthalene and 43 parts by mass of γ-butyrolactone.

[0087] The negative photoresist composition was coated on a silicon wafer with a spin coater, and then prebaked at 60° C. for 5 minutes and 90° C. for 5 minutes on a hot plate to obtain an organic film with a film thickness of 30 μm. The organic film was pressed against the organic film at 90° C. for 1 minute using a NM401 Imprinter (manufactured by Ming Chang Kiko Co., Ltd.) under a pressing condition of 200 N. Thereafter, the substrate was cooled to 23° C.,...

Embodiment 2

[0092] A negative electrode substrate was formed in exactly the same manner as in Example 1, except that the negative resist composition used in Example 1 was changed to the following positive resist composition.

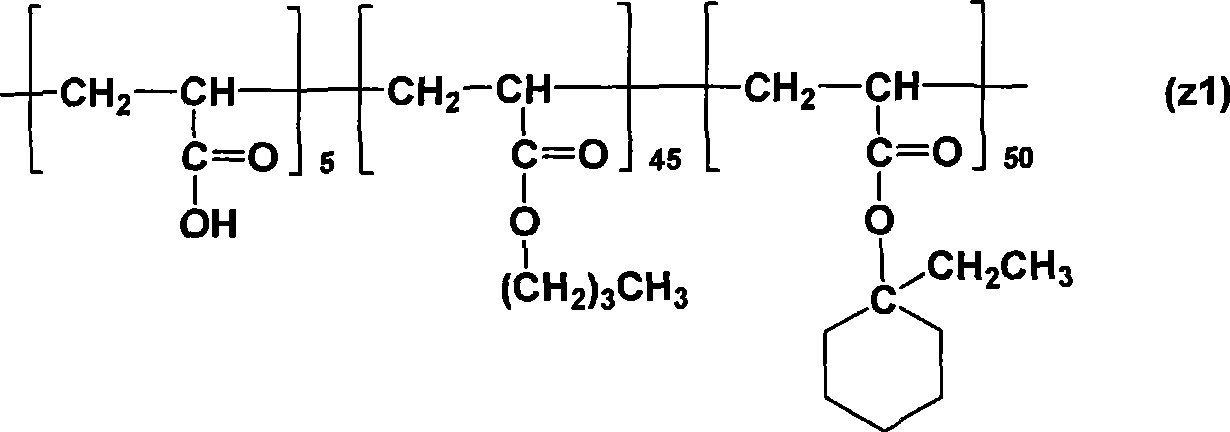

[0093] 1 part by mass of [2-(propylsulfonyloxyimino)-2,3-dihydrothiophene-3-ylidene](o-tolyl)acetonitrile (IRGACURE PAG103 (trade name), Ciba Specialty Chemicals (manufactured by Ciba Specialty Chemicals), 40 parts by mass of the resin represented by the following structural formula (z1) that can increase the solubility of alkali by the action of an acid, 60 parts by mass of formaldehyde and an acid catalyst in the presence of The phenolic resin obtained by addition condensation of m-cresol and p-cresol and 1 part by mass of 1,5-dihydroxynaphthalene are uniformly dissolved in propylene glycol monomethyl ether acetate and passed through a filter with a pore size of 1 μm The membrane was filtered to obtain a positive photoresist composition with a solid content mass c...

Embodiment 3

[0103] 100 parts by mass of multifunctional bisphenol A novolac epoxy resin "Epikote 157S70 (trade name, manufactured by Japan Epoxy Resin Co., Ltd.)", 5 parts by mass of diphenyl [4-(phenylthio) phenyl] A mixture of sulfonium hexafluorophosphate and thiodiphenylene bis(diphenylsulfonium)bis(hexafluorophosphate) "UVI-6992 (trade name, manufactured by Dow Chemical Company)", 5 parts by mass of 1, A negative photoresist composition was prepared by mixing 5-dihydroxynaphthalene and 43 parts by mass of γ-butyrolactone.

[0104] The photoresist composition was spin-coated on a silicon wafer, and prebaked at 60° C. for 5 minutes and then at 90° C. for 5 minutes to form an organic film with a film thickness of 30 μm. Using NM401 Imprinter (manufactured by Mingchang Machinery Co., Ltd.), under the pressing condition of 200N, the quartz mold was pressed on the organic film for 5 minutes. Co., Ltd.) irradiate the entire substrate with an ultra-high pressure mercury lamp (exposure amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com