Chinese medicine rapid-release preparation for oral cavity and method for producing the same

A technology of quick-release preparations and manufacturing methods, which is applied in the field of traditional Chinese medicine preparations, can solve the problems of low tablet strength, large amount of excipients, discomfort, etc., and achieve the effect of taking convenience and improving the dispersion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

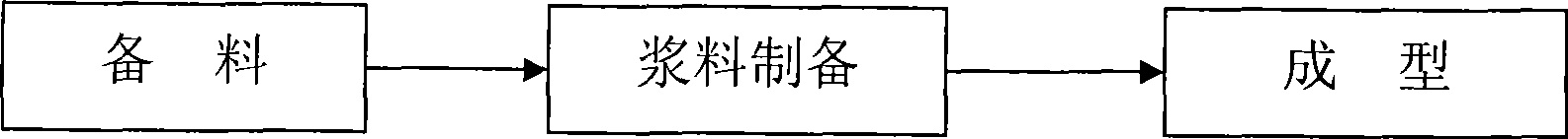

[0118] Embodiment 1: the manufacture method of Shengmai preparation

[0119] (1) Material preparation: main ingredients (ginseng 100Kg, Ophiopogon japonicus 200Kg, Schisandra chinensis 100Kg), auxiliary materials (sugar 300Kg, hydrogenated vegetable oil 300Kg, lecithin 10kg)

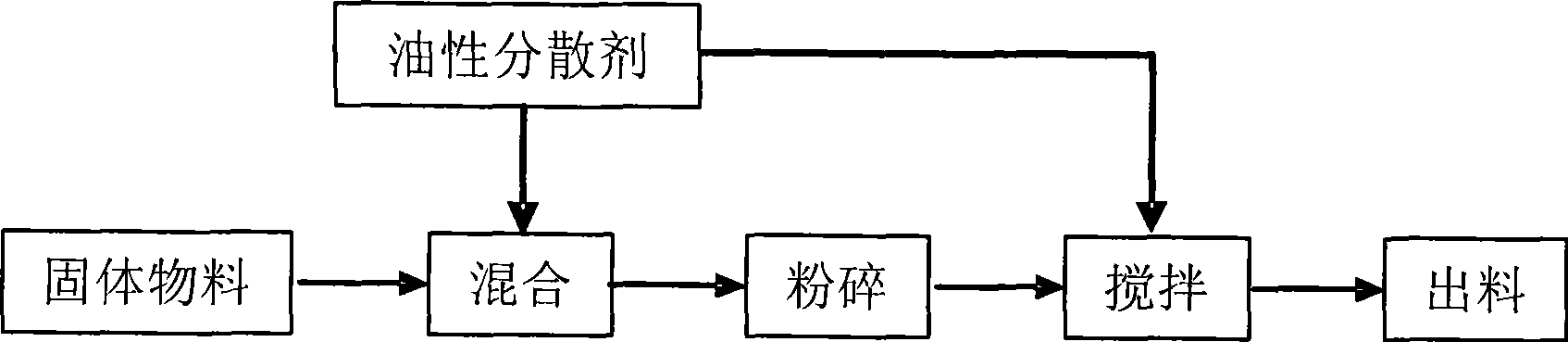

[0120] (2) Slurry preparation: Semi-dry method, roller grinding method (see Figure 6 ). Specifically: crush 100Kg of ginseng, 200Kg of Ophiopogon japonicus, and 100Kg of schisandra to 200 mesh, add 300Kg of white sugar and 180Kg of hydrogenated vegetable oil (35-60°C), mix them, and pre-grind them in a two-roll mill (or three-roll mill) to 60- 150 microns, and then enter the five-roll mill (or three-roll mill) for grinding to 20-35 microns. Then put the material into a mixer (refiner) and stir (refine) for 5 hours, during which 90Kg of hydrogenated vegetable oil is gradually added according to the viscosity of the material, and 30Kg is reserved to add together with lecithin 1 hour before the end. Thi...

Embodiment 2

[0122] Embodiment 2: the manufacture method of Shengmai preparation

[0123] (1) Material preparation: main ingredients (ginseng 100Kg, Ophiopogon japonicus 200Kg, Schisandra chinensis 100Kg), auxiliary materials (sugar 300Kg, hydrogenated vegetable oil 300Kg, lecithin 10kg)

[0124] (2) Slurry preparation: wet method, fine grinding method (see Figure 7 ). Specifically: Grind 100Kg ginseng, 200Kg Ophiopogon japonicus, and 100Kg schisandra chinensis to 200 mesh, add 300Kg sugar powder and 270Kg hydrogenated vegetable oil (35-60°C) successively (or add after mixing) and grind them to 25 microns . Reserve 30Kg of hydrogenated vegetable oil and add it together with lecithin 1 hour before the end.

[0125] (3) Molding: after fine grinding, discharge the material, pour it into a pre-set mold, then cool and solidify, take it out of the package, 10g / piece.

Embodiment 3

[0126] Embodiment 3: the manufacture method of Shengmai preparation

[0127] (1) Material preparation: main ingredients (ginseng 100Kg, Ophiopogon japonicus 200Kg, Schisandra chinensis 100Kg), auxiliary materials (sugar 300Kg, hydrogenated vegetable oil 300Kg, lecithin 10kg)

[0128] (2) Slurry preparation: adopt wet method, ball milling method (see Figure 8 ). Specifically: Grind 100Kg ginseng, 200Kg Ophiopogon japonicus, and 100Kg schisandra chinensis to 200 mesh, add 300Kg white sugar (or powdered sugar) and 300Kg hydrogenated vegetable oil (35-60°C) successively (or add after mixing) in a ball mill and grind to 25 microns . Lecithin is added successively during the grinding process.

[0129] (3) Molding: Discharge after ball milling, pour into a pre-set mold, then cool and solidify, take out the package, 10g / piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com