Plant fibre cable coil bidirectional friction extrusion molding device

A plant fiber and extrusion molding technology, applied in the field of mechanical equipment, can solve the problems of uneven axial compaction density of the reel, difficulty in demoulding, and large volume change, etc., to achieve low damage rate, great social benefits and environmental protection Benefits, the effect of meeting the needs of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

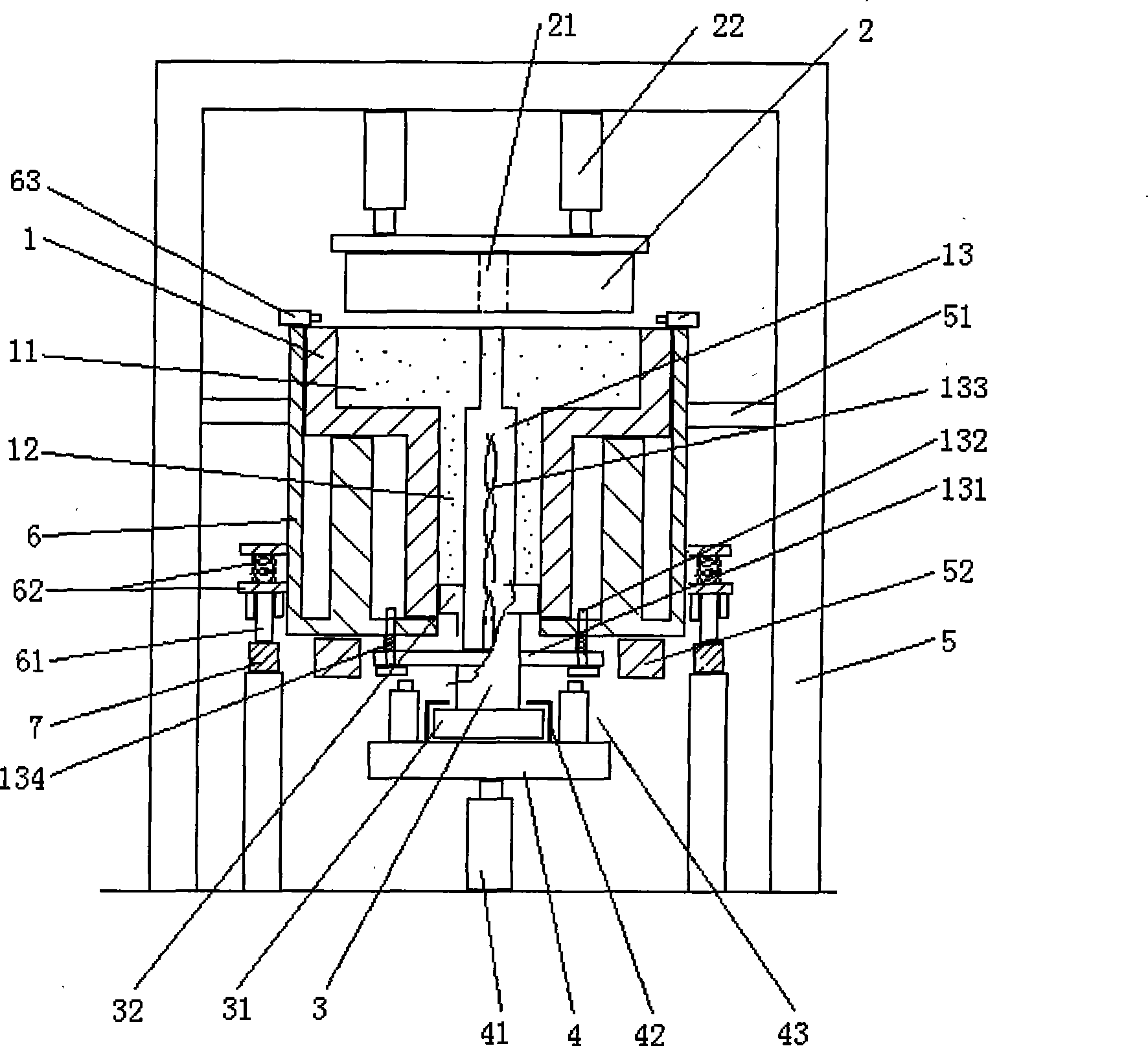

[0018] Such as figure 1 As shown, the present invention includes a female die 1, an upper die punch 2, a lower die punch 3, a core rod 13 located in the cavity of the female die 1, the core rod 13 is movably connected with the lower die punch 3, and an upper die punch 2 is a power device that is pressed into the cavity of the female mold 1.

[0019] still as figure 1 As shown, the disc cavity 11 of the female mold 1 is connected to the reel cavity 12, the core rod 13 is arranged in the reel cavity 12, and the upper end of the core rod 13 passes through the bottom surface of the disc cavity 11 of the female die 1 , continue to go up until it is parallel to the upper opening of the female mold 1. The upper end of the core rod 13 passing through the bottom surface of the disc cavity of the female mold 1 has a diameter smaller than the diameter of the core rod 13 below the bottom surface of the disc cavity. The upper die punch 2 is provided with a hole 21 matching the upper end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap