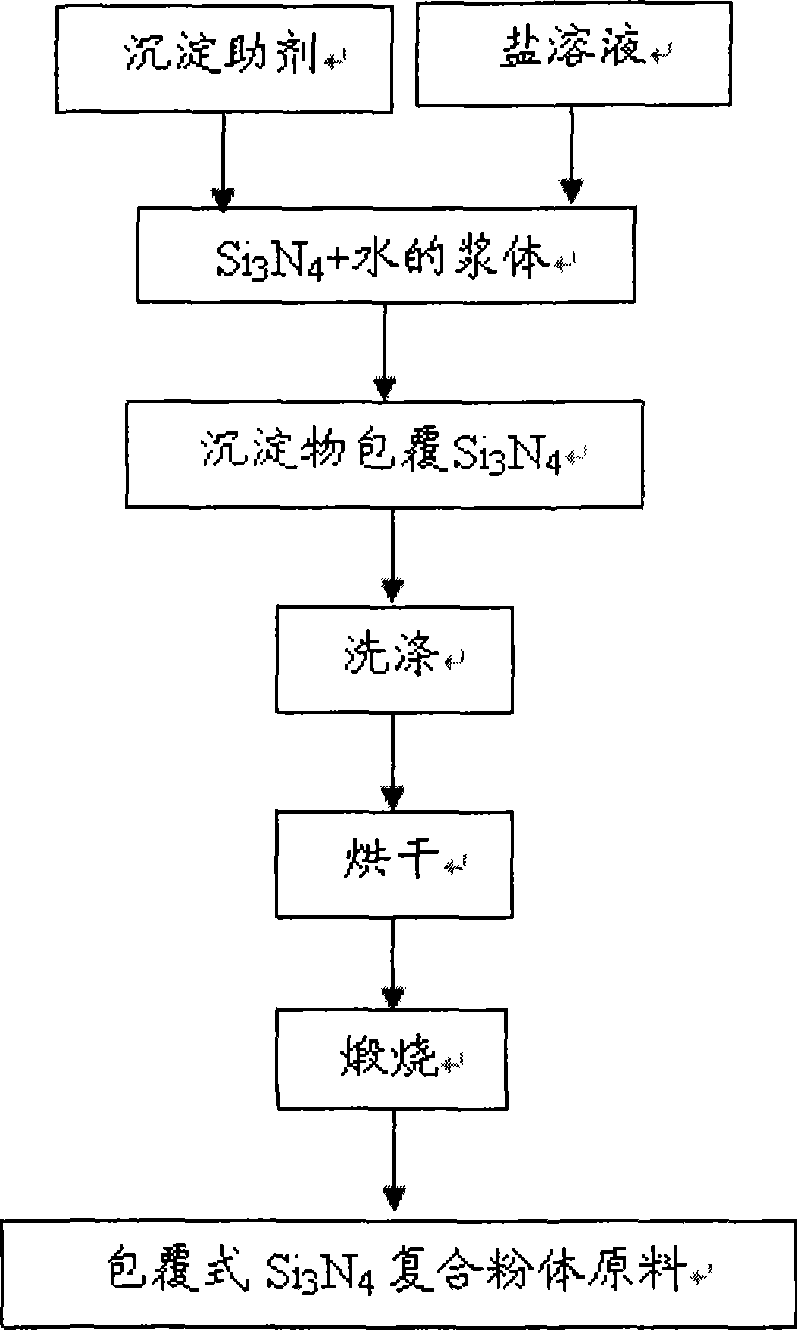

Chemical preparation method of core-shell Si3N4 compound powder

A composite powder and core-shell technology, applied in chemical instruments and methods, inorganic chemistry, nitrogen compounds, etc., to achieve the effects of easy control, excellent physics, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 3 g Si 3 N 4 Add the powder into 200ml of water, ultrasonically disperse for 5 minutes, stir evenly, and use 180 minutes to Si 3 N 4 Add 300ml of the mixed solution (150ml of 0.09mol / L aluminum nitrate and 150ml of 0.15mol / L yttrium nitrate) dropwise into the slurry at a constant speed, and drop into the precipitant ammonia water with pH=11 to adjust ZrB 2 The pH value of the slurry was always 9, and the stirring was continued with a stirrer. After the dropwise addition of the mixed solution was completed, the stirring was continued for 1 hour, and the pH value was kept at 9. The precipitate was separated by centrifugation, washed three times with deionized water, and then washed once with absolute ethanol, dried at 80°C, and calcined at 500°C to obtain Al 2 o 3 and Y 2 o 3 common putamen ZrB 2 Core-shell Si of powder particles 3 N 4 Composite powder raw material.

Embodiment 2

[0018] 3 g Si 3 N 4 Add the powder into 100ml of water, ultrasonically disperse for 5 minutes, stir evenly, and use 120 minutes to Si 3 N 4 Add 200ml of 0.04mol / L zirconium hypochlorite solution dropwise into the slurry at a constant speed, and at the same time drop into the precipitant ammonia water with pH=11 to adjust Si 3 N 4 The pH value of the slurry was always 5, and the stirring was continued with a stirrer. After the dropwise addition of the mixed solution was completed, the stirring was continued for 1 hour, and the pH value was kept at 5. The precipitate was separated by centrifugation, washed three times with deionized water, and then washed once with absolute ethanol, dried at 100°C, and calcined at 700°C to obtain ZrO 2 shell core Si 3 N 4 Core-shell Si of powder particles 3 N 4 Composite powder raw material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com