Fluidized calcining technology of high-activity metakaolin

A technology of metakaolin and calcination process, which is applied in the field of calcination process of silicate materials, which can solve the problems that the speed is difficult to meet the requirements of high-activity metakaolin calcination, the quality is difficult to achieve and stabilize, and the heat loss is large, so as to facilitate the expansion of large-scale production , good quality stability, and obvious energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

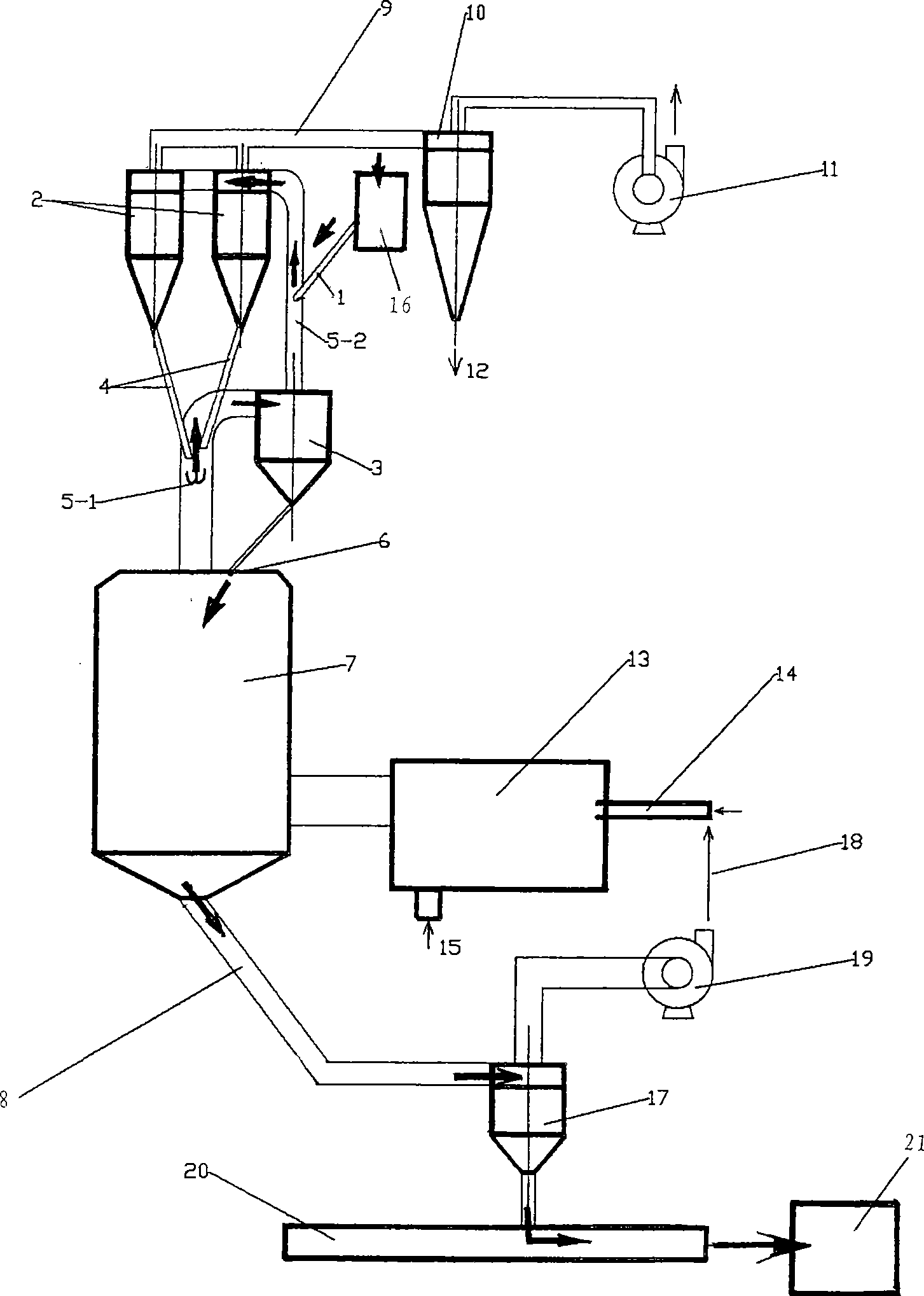

[0028] Embodiment 1, adopt 180 purpose kaolin powder body material, send into such as figure 1 In the technological process, when the temperature of the hot flue gas output by the hot blast furnace is 800°C, and the cross-sectional flow velocity of the counterflow calciner is 1 m / s, the properties of the obtained metakaolin are: particle size distribution after grinding D 50 =1,89μm, Ca(OH) 2 Absorption value 1280mg / g.

Embodiment 2

[0029] Embodiment 2, adopt 320 purpose kaolin powder body materials, send into such as figure 1 In the technological process, the temperature of the hot flue gas output by the hot blast stove is 1000°C, and the cross-sectional flow velocity of the counterflow calciner is 2.5 m / s. The properties of the obtained metakaolin are: particle size distribution after grinding D 50 =2.36μm, Ca(OH) 2 Absorption value 1250mg / g.

Embodiment 3

[0030] Embodiment 3, adopt 320 purpose kaolin powder body materials, send into such as figure 1 In the technological process, the temperature of the hot flue gas output by the hot blast stove is 950°C, and the cross-sectional flow velocity of the counterflow calciner is 2.0 m / s. The properties of the obtained metakaolin are: particle size distribution after grinding D 50 =2.03μm, Ca(OH) 2The absorption value is 1325mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com