Technique for recovering zinc chloride from waste water in reduction process of isooctyl thioglycolate

A technology of isooctyl mercaptoacetate and isooctyl acetate, which is applied in the field of recycling zinc chloride and hydrogen chloride, can solve problems such as increasing production costs, increasing waste water volume, and polluting the environment, and achieves waste reduction, pollution elimination, and production reduction cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

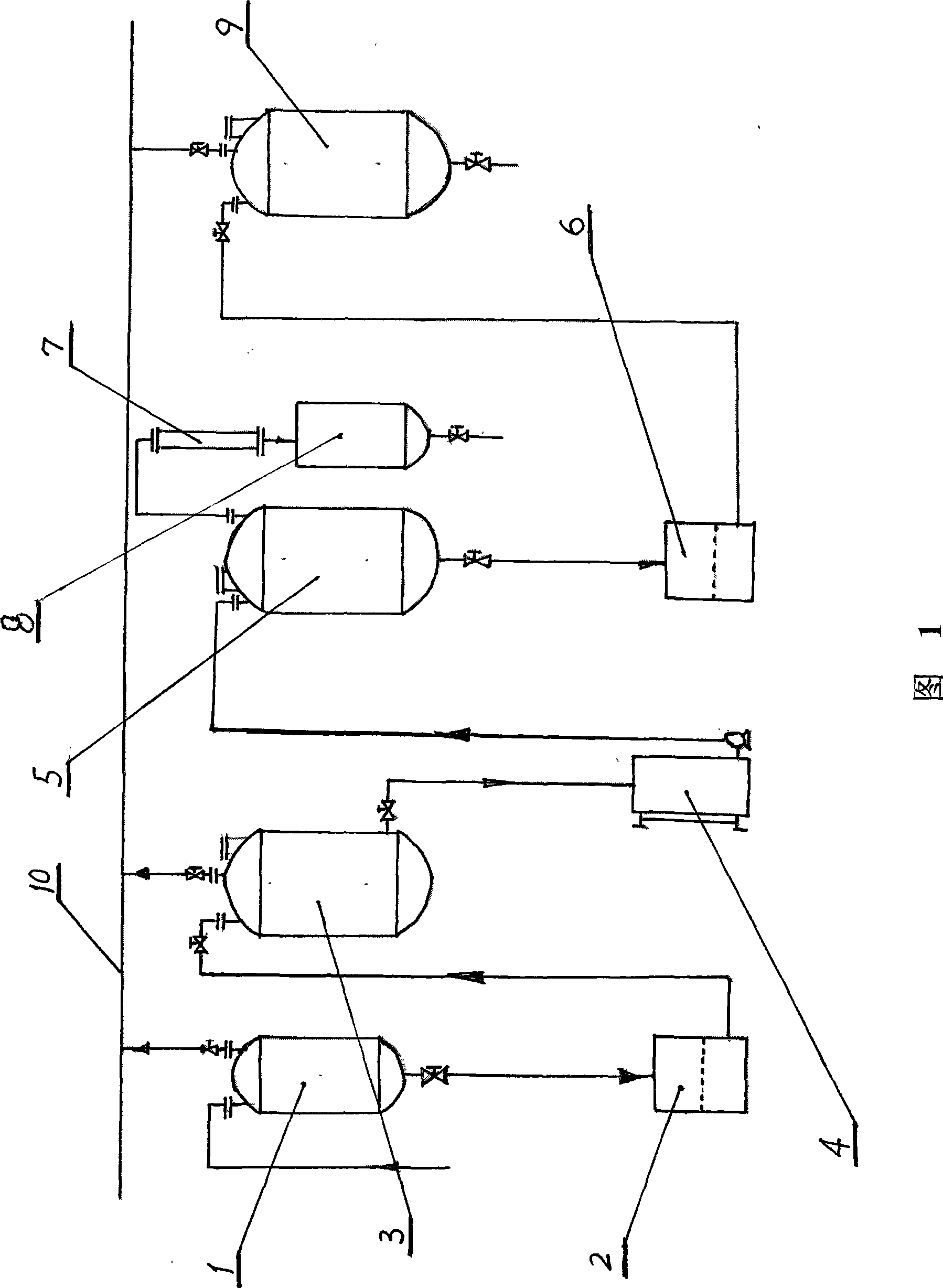

[0009] A process for recovering zinc chloride from waste water in the reduction process of isooctyl thioglycolate. The process equipment mainly includes vacuum tube 10, storage tank 1, suction filter tank 2, settling tank 3, metering tank 4, concentration kettle 5, suction filter tank 6, condenser 7, hydrochloric acid product storage tank 8 and zinc chloride product storage tank 9. The upper parts of storage tank 1, settling tank 3 and zinc chloride product storage tank 9 are respectively connected with vacuum pipe 10 through valves. After recovering the waste water produced in the reduction process of isooctyl thioglycolate, it is pumped into the storage tank 1 by a vacuum pump for static precipitation at normal temperature. Connect the storage tank 1 and the vacuum pipe 10 to remove the organic matter floating on the upper layer. After the remaining solution in the storage tank 1 is filtered out of solid impurities such as zinc slag through the suction filter tank 2 by a v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com