Micro-complex type method for inducing electric field under the restrict of non-contact moulding board

A technology of electric field induction and micro-replication, which is applied in the direction of photolithography, optics, and optomechanical equipment on the pattern surface, which can solve the problems of unfavorable multi-layer overlay and replication, reduce processing costs and improve production efficiency , the effect of shortening the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below, the process of the electric field-induced micro-replication method under the constraint of a non-contact template will be described in detail in conjunction with the accompanying drawings:

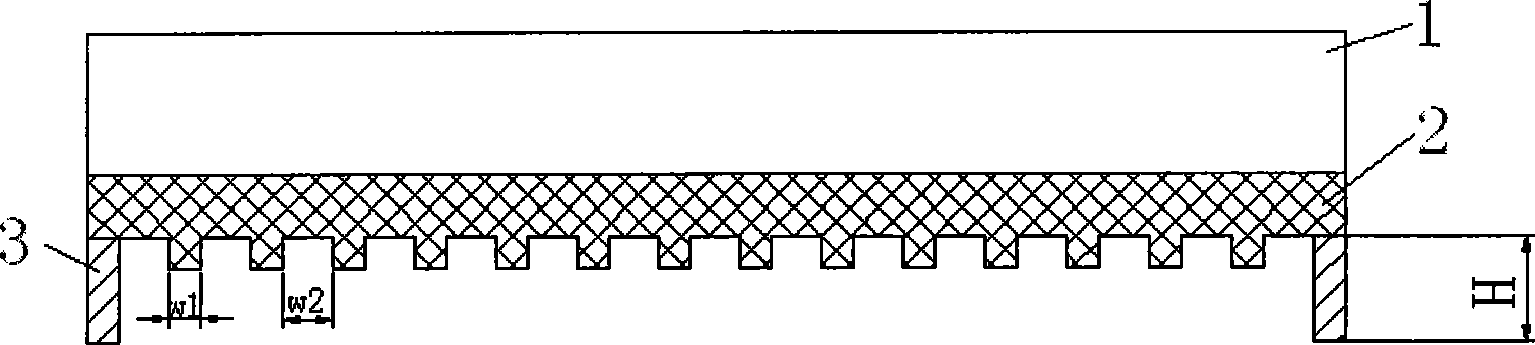

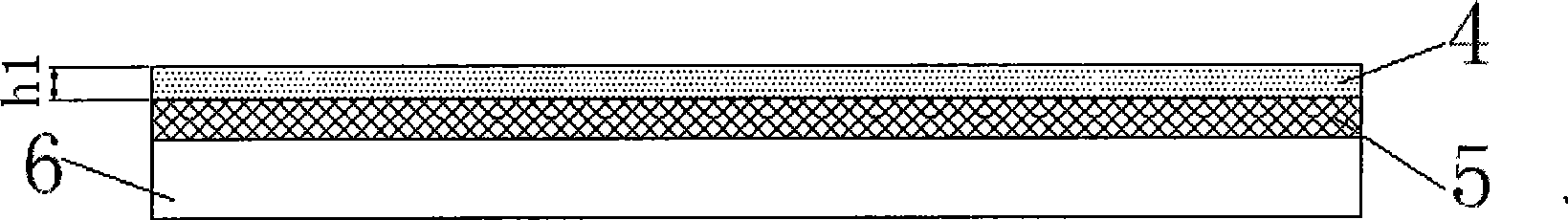

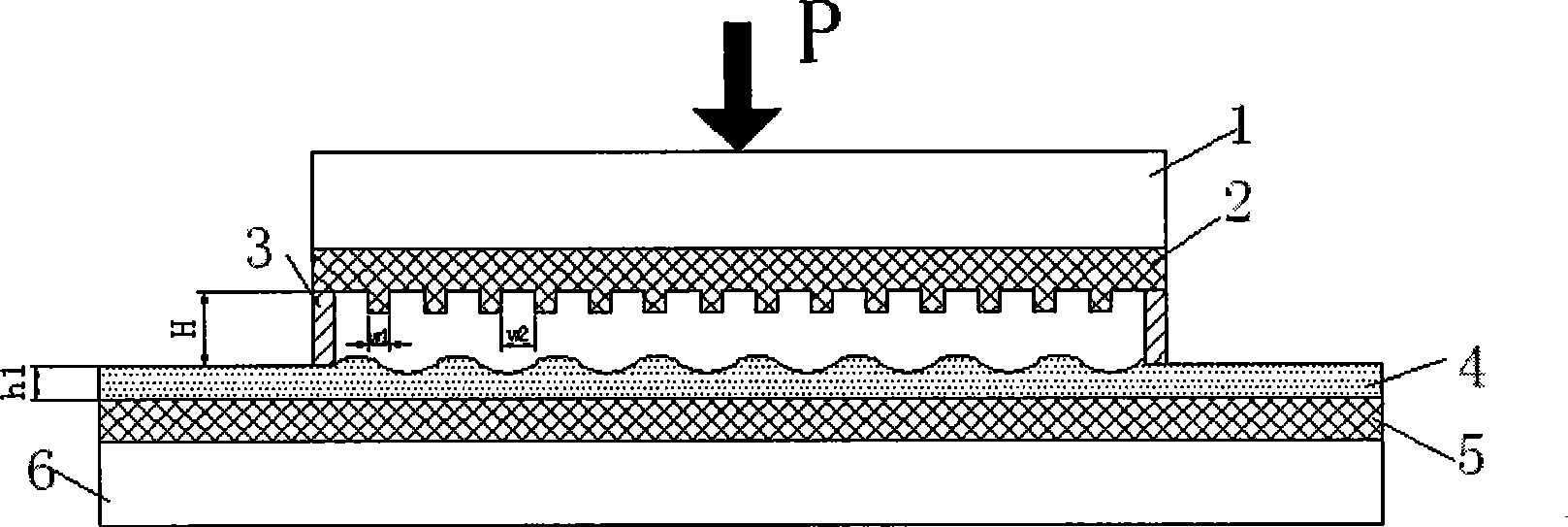

[0025] As shown, in SiO 2 The surface of the substrate 1 is vapor-deposited with a nano-indium tin metal oxide ITO glass layer 2, and the process of patterning and processing the supporting part 3 is carried out, as shown in the attached figure 1 shown in SiO 2 The surface conductive indium tin metal oxide ITO glass layer 5 on the surface of the substrate 6, and the process of spin-coating the corrosion resist adhesive layer 4 on the surface of the conductive indium tin metal oxide ITO glass layer 5, as attached figure 2 As shown, the process of pressing the prepared template on the corrosion resist adhesive layer 4 with a pressure of 20MPa, as shown in the attached image 3 shown in the template and SiO 2 The process of indirect DC power supply 7 between the substrates f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com