Method for preparing halogen free flame-retarded nylon 6

A technology of flame-retardant nylon and mass parts, which is applied in the field of preparation of halogen-free flame-retardant nylon 6, which can solve the problems of increasing the cost of raw materials for users, only being used in the plastics industry, and increasing the manufacturing cost of flame-retardant nylon 6.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

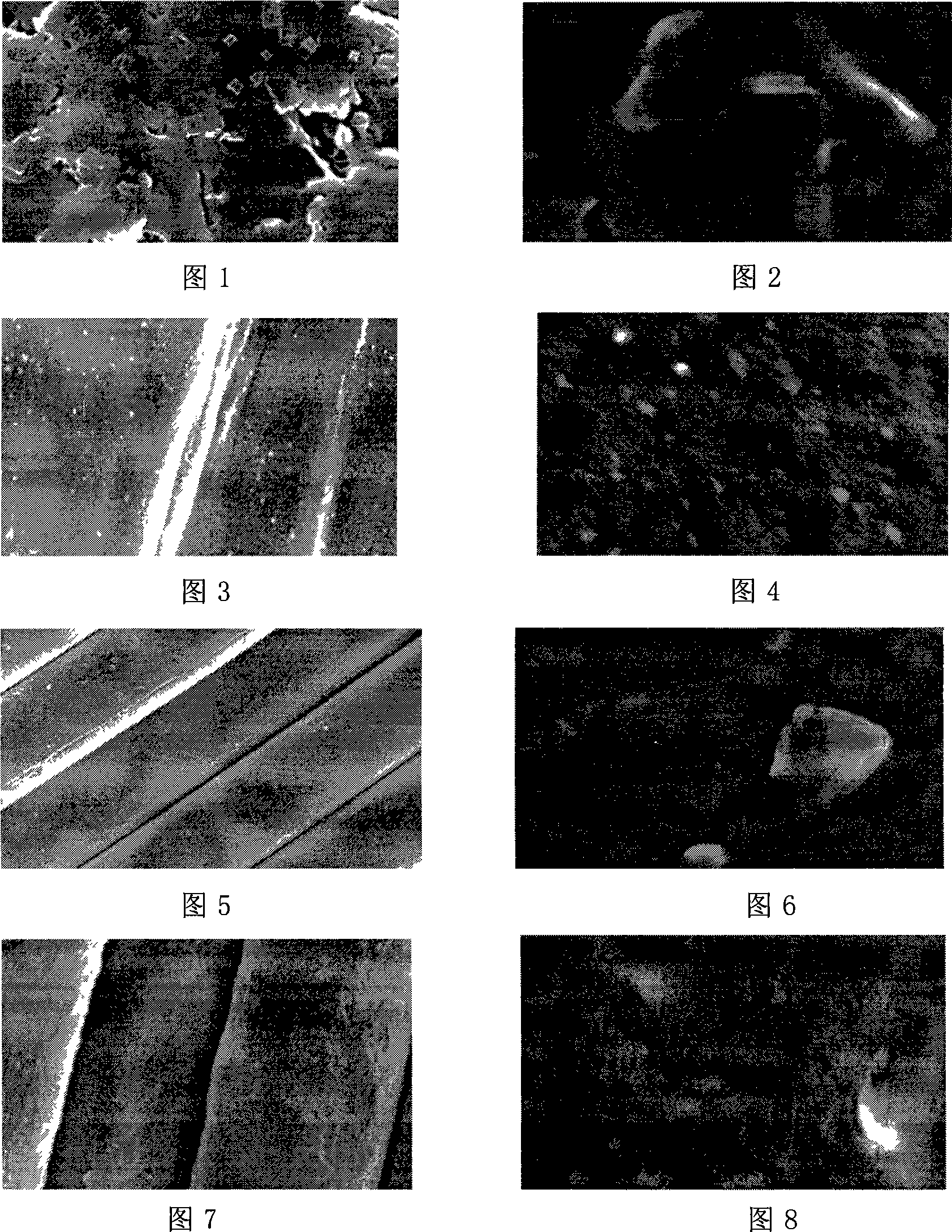

Image

Examples

Embodiment 1

[0034] Example 1: In a 10-liter polymerization kettle, 2.9 parts of adipic acid and 2.47 parts of melamine were added and stirred for 3 hours at 50° C., then centrifugally filtered, and the prepared adipate melamine salt and 2.3 parts of hexamethylenediamine were dried. Stir and react with 2.53 parts of cyanuric acid at 80°C for 0.5 hours, then centrifuge and filter, dry the prepared two flame-retardant monomers of hexamethylenediamine cyanurate, 1 part of pentaerythritol, and 0.01 part of tungstic acid. The substance is pre-dispersed and mixed with a high-shear emulsifier, 88.79 parts of molten caprolactam, and 0.3 part of water, and then heated to 230-265°C and stirred for 5 hours under a pressure of 0.2-0.8 MPa. Vacuum removal of low-molecular weight, discharge casting tape pelletization, and obtain halogen-free flame-retardant nylon 6 particles. After extraction and drying, samples are obtained for flame-retardant and mechanical performance testing. The results are shown i...

Embodiment 2

[0035] Example 2: In a 10-liter polymerization kettle, put 2.47 parts of melamine, 2.53 parts of cyanuric acid, 5.2 parts of nylon 66 salt, 1 part of pentaerythritol, and 0.01 part of tungstic acid. Pre-disperse and mix molten caprolactam and 0.3 parts of water, then raise the temperature to 230-265°C, and stir the polymerization reaction for 8 hours at a pressure of 0.2-0.8 MPa, then release the pressure, decompress and vacuumize to remove low molecules, and discharge the material to cast and cut into pellets , the obtained halogen-free flame-retardant nylon 6 particles were extracted and dried, and the samples were obtained for flame-retardant and mechanical performance testing. The results are shown in Table 1.

Embodiment 3

[0036] Embodiment 3: first in the colloid mill, drop into by 2.9 parts of adipic acid and 2.47 parts of melamine at 95 DEG C and stir and react for 1.5 hours, then centrifuge and filter, dry the prepared melamine adipate, 2.3 parts of hexamethylenediamine and 2.53 parts of cyanuric acid were stirred and reacted at 50°C for 2 hours, then centrifugally filtered, and dried to obtain two flame-retardant monomers composed of hexamethylenediamine cyanurate, 1 part of pentaerythritol, 0.01 part of tungstic acid and 88.79 parts The molten caprolactam and 0.3 parts of water are pre-dispersed and mixed; then the pre-dispersed mixed solution is pumped into the polymerization tank, the temperature is raised to 230-265 ° C, and the pressure is 0.2-0.8 MPa to stir the polymerization reaction for 5-8 hours, and then unload Pressure, decompression and vacuum pumping to remove low molecular weight, discharge material, cast belt and cut pellets to obtain halogen-free flame-retardant nylon 6 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com