Low loss multilayered circuit board

A multi-layer circuit board and circuit technology, which is applied to printed circuit components, measuring electricity, measuring electrical variables, etc., to achieve the effect of making good use of circuit space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, several preferred embodiments are listed with reference to the accompanying drawings to describe the structure and functions of the present invention in detail.

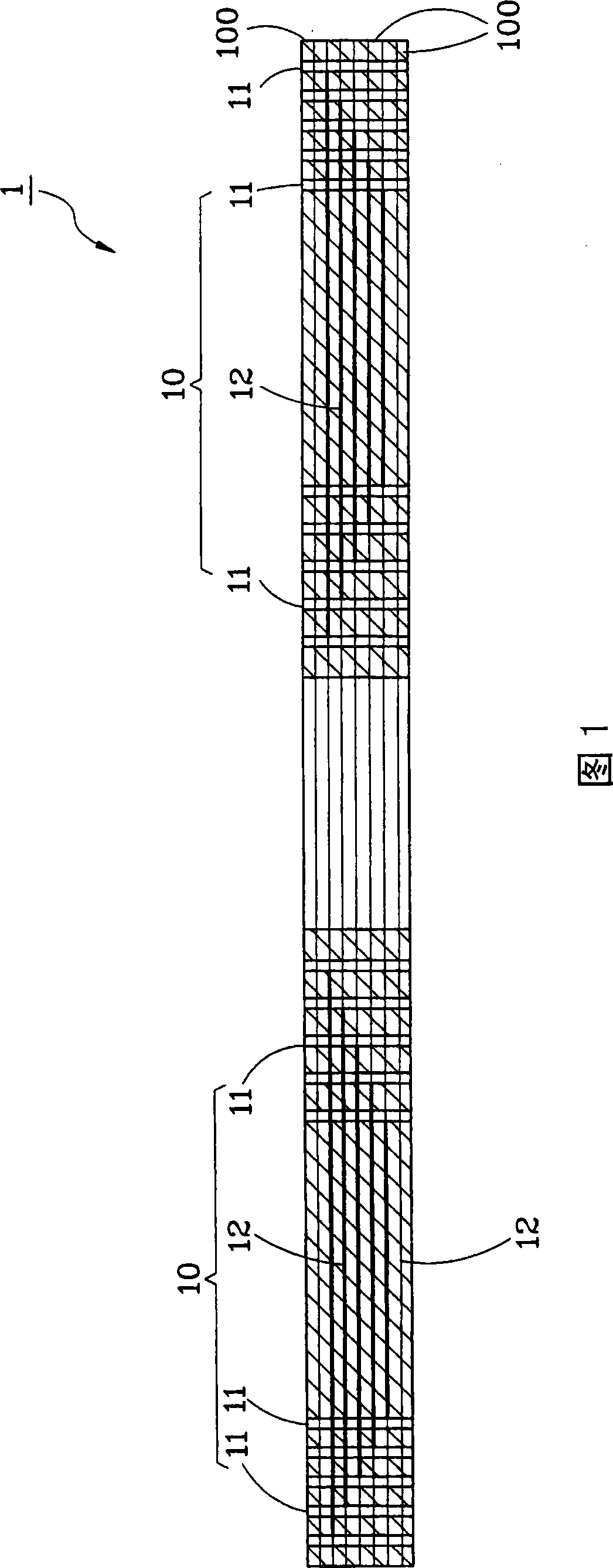

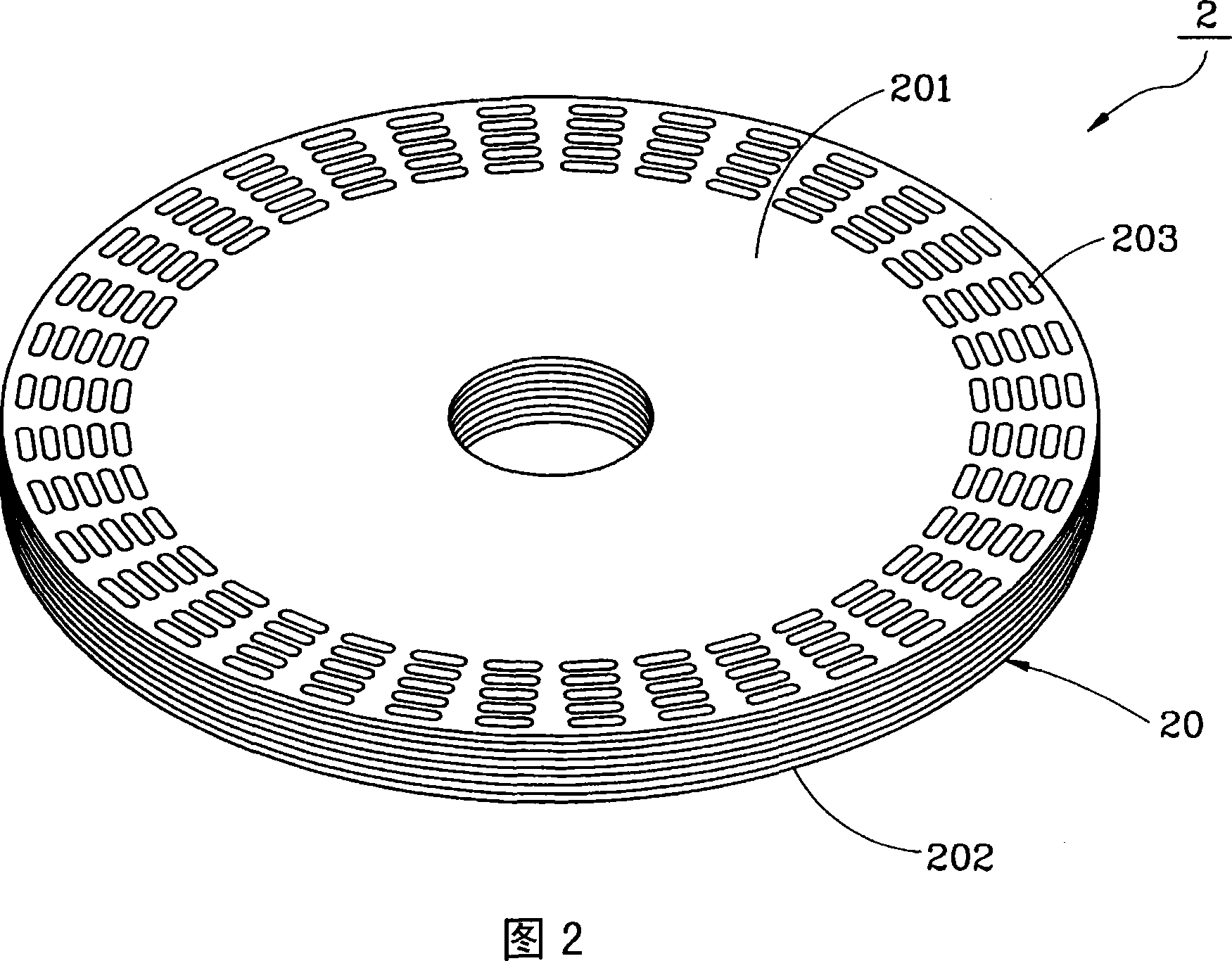

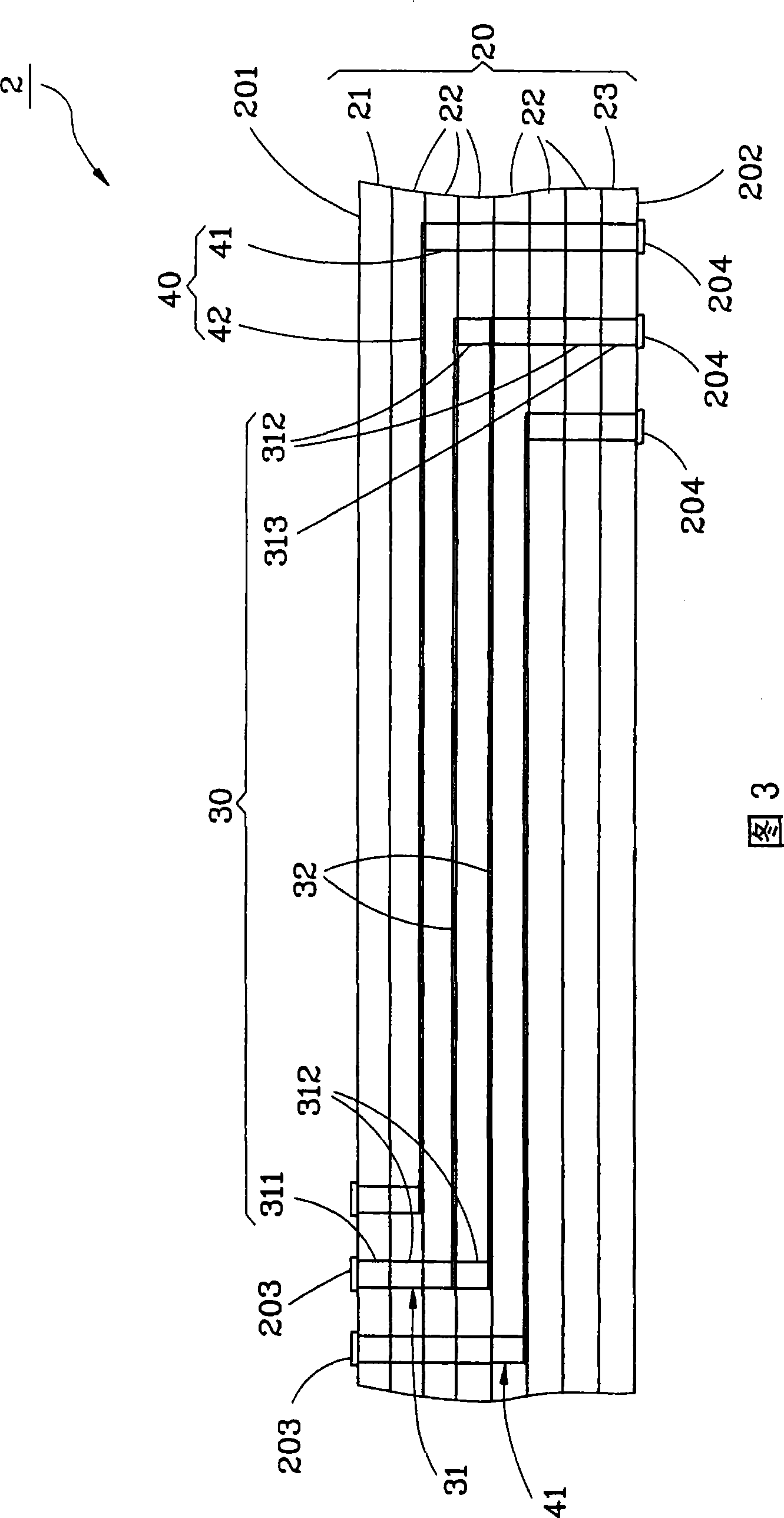

[0042] Please refer to a multilayer circuit board 2 provided by the most preferred embodiment of the present invention as shown in Fig. 2 to Fig. 4, be the multilayer printed circuit board of approximate integrated circuit wafer size, be used on the wafer test probe card , can perform electrical tests on a wide range of wafer circuit components at a time, lay out a plurality of signal circuits 30 and grounding circuits 40 with high-frequency transmission line characteristics on a plurality of substrates 20 with good insulation characteristics, and then place these substrates 20 are stacked and pressed together. The multilayer circuit board 2 has an upper and lower surface 201, 202 opposite to each other. A plurality of upper solder joints 203 are arranged near the upper surface 201, and a plurality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com