Micro-nano fabrication method for auxiliary etch by combining focused ion beam injection and xenon fluoride gas

A focused ion beam, gas-assisted technology, applied in the process of producing decorative surface effects, microstructure technology, gaseous chemical plating, etc., can solve problems affecting processing accuracy, improve processing quality, reduce impact, The effect of improving the efficiency of structure preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

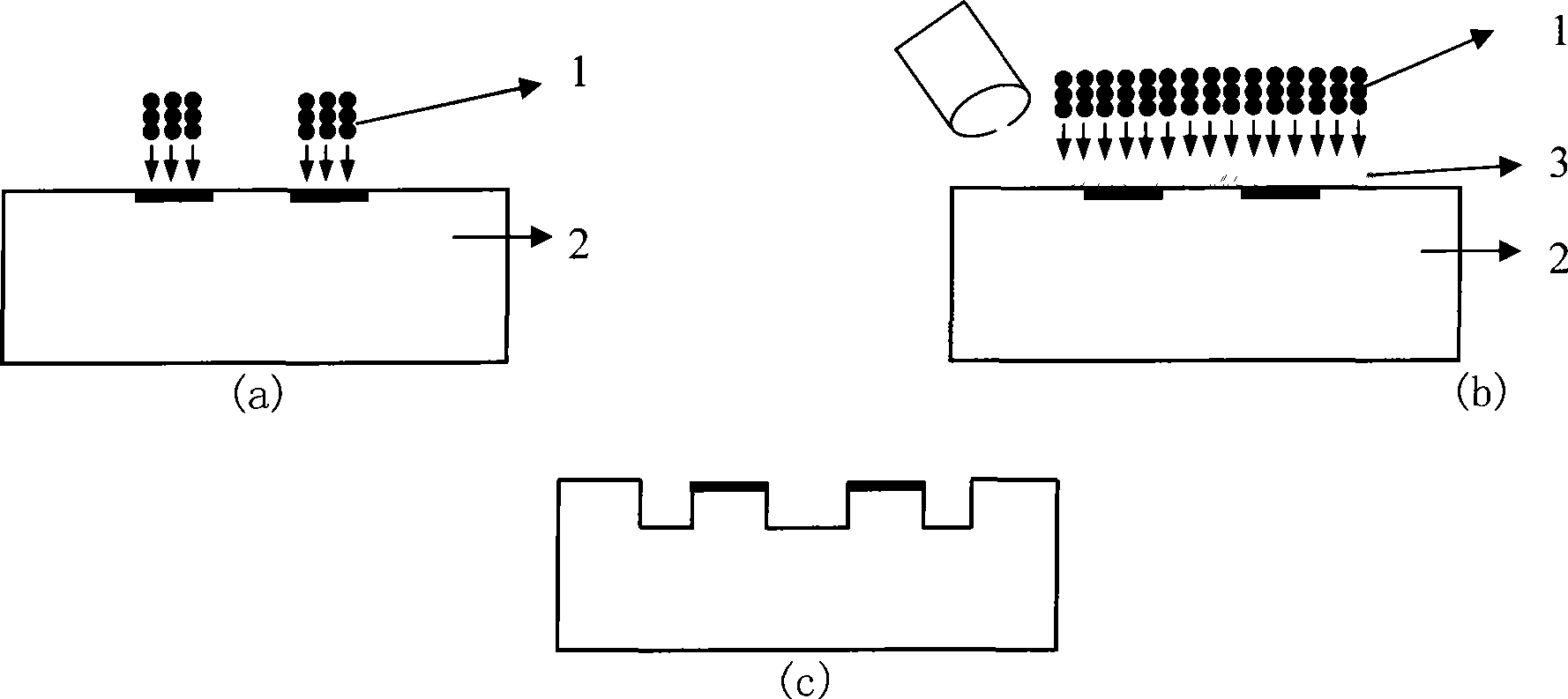

Method used

Image

Examples

Embodiment 1

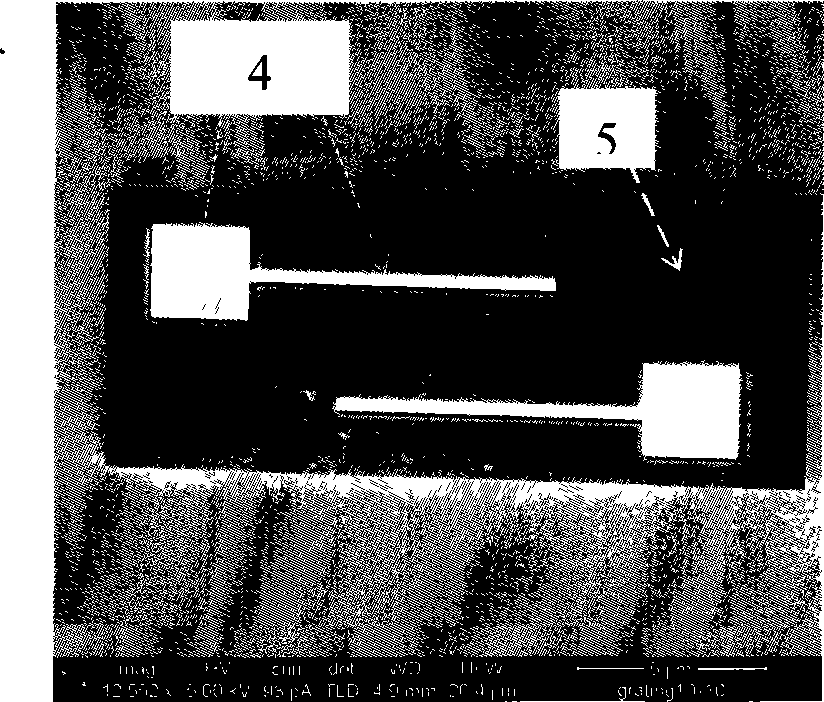

[0026] Using 30kV accelerating voltage and 30pA gallium ion beam, with 1.4×10 21 ion / m 2 Ion dose Ion implantation was performed on the monocrystalline silicon sample, the implantation time was 210 seconds, and the ion implantation method was uniform implantation. Subsequently, XeF was performed with a beam current of 30kV and 30pA 2 The gas-assisted etching is performed for 8 seconds, and the processing range of the assisted etching is 18 microns×12.5 microns. After the auxiliary etching is stopped, a microelectrode structure with a height of about 100 nanometers protruding from the ion implantation area will be generated, such as figure 2 shown.

Embodiment 2

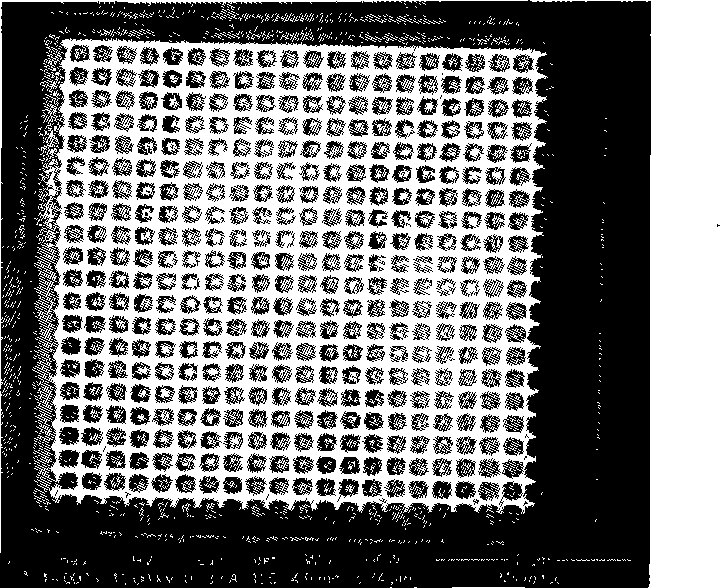

[0028] The single crystal silicon sample was implanted with 30kV accelerating voltage and 30pA gallium ion beam. The ion implantation method was implanted according to the law of the grating structure. The ion implantation processing range was 5 microns*5 microns, and the ion implantation time was 40 seconds. Subsequently, XeF was performed with a beam current of 30kV and 30pA 2 The gas-assisted etching is performed for 2 seconds, and the processing range of the assisted etching is 5.5 microns×5.8 microns. After the auxiliary etching is stopped, a micro-grating structure with a depth of about 100 nanometers will be generated with the ion implantation region as a protrusion, such as image 3 shown.

Embodiment 3

[0030] The single crystal silicon sample was implanted with 30kV accelerating voltage and 50pA gallium ion beam. The ion implantation was carried out according to the sinusoidal distribution law. The implantation time of a single micro-sine structure was 60 seconds, and the micro-sine diameter was 5 microns. sinusoidal structure. Subsequently, XeF was performed using 10kV and 23pA beam current 2 The gas-assisted etching is performed for 15 seconds, and the processing range of the assisted etching is 21 microns×21 microns. After the auxiliary etching is stopped, a micro-sinusoidal structure with a peak-to-valley value of about 100 nanometers protruding from the ion implantation region will be generated, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com