Process for directly producing sponge iron by microwave carbothermal reduction steel metallurgical iron-bearing dust

A technology of iron and steel metallurgy and sponge iron, which is applied in the direction of furnaces, furnace types, fluidized bed furnaces, etc., can solve the problems of large production site area, high investment costs, and large energy consumption, so as to reduce energy consumption and improve production efficiency Effect of high and low activation energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

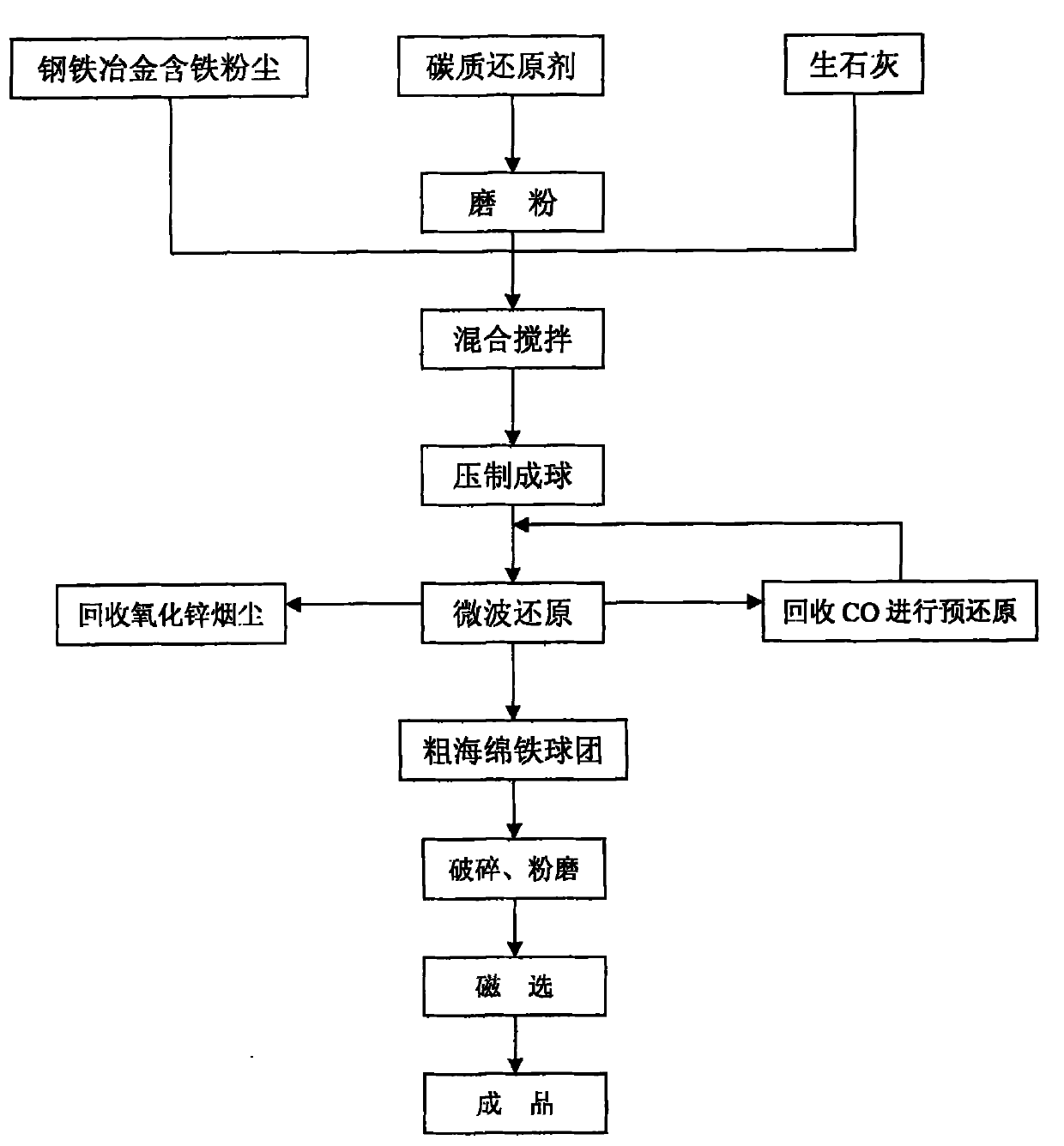

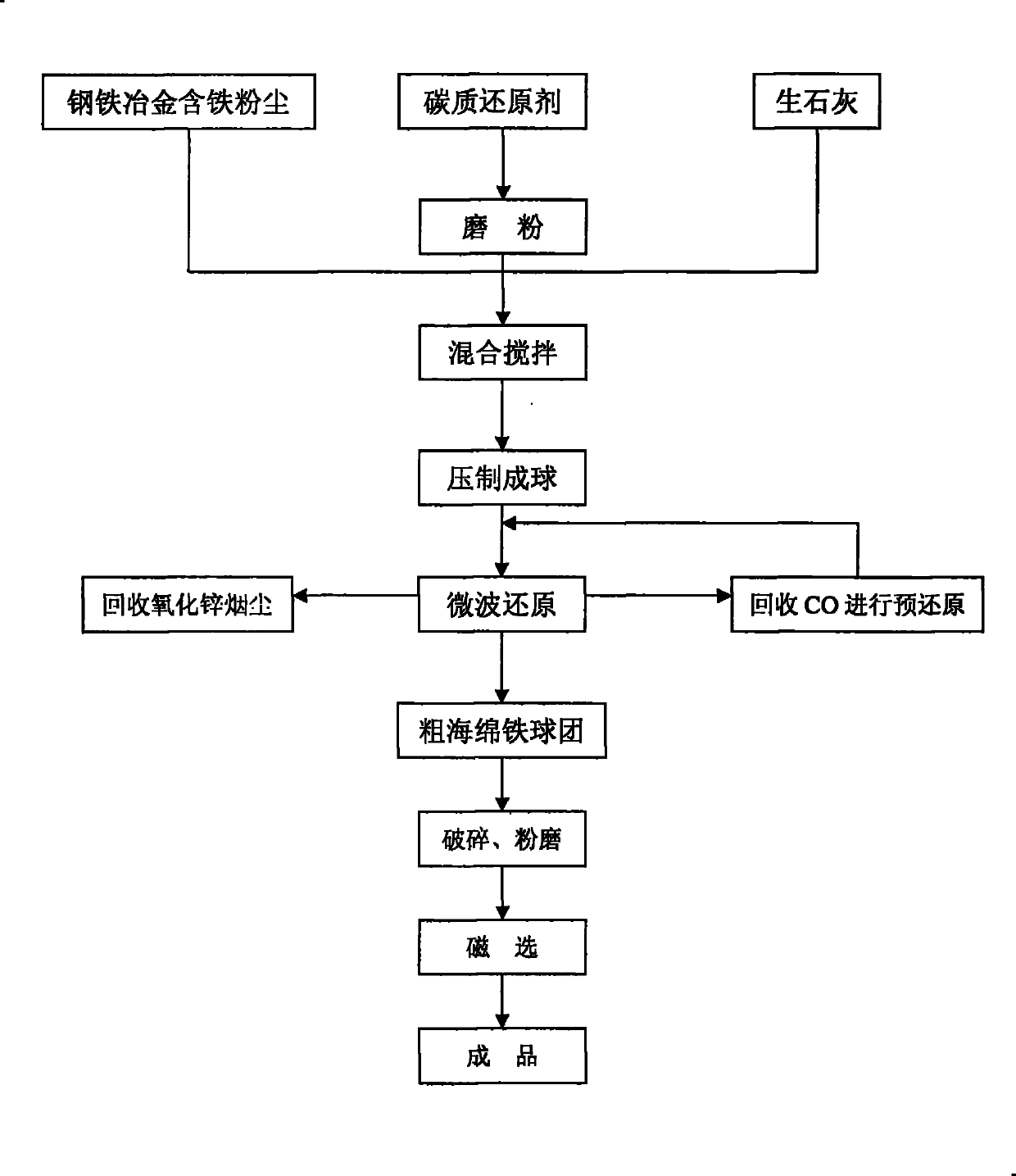

[0019] As shown in the figure, in the microwave carbothermal reduction production process of the present invention of the present invention sponge iron, the process method is: various iron and steel metallurgical iron-containing dust, such as converter dust removal powder, electric furnace dust removal dust, blast furnace dust removal powder, coke oven Dust removal powder, etc., according to its iron oxide and carbon content, add anthracite as a reducing agent in proportion, the iron and steel metallurgy iron-containing dust weight ratio accounts for 20-80% of the total weight, and the anthracite weight ratio accounts for 10-80% of the total weight 60%, and add 1-20% quicklime as an additive, after drying, make pellets with a diameter of 2mm-100mm, put them into a microwave reduction furnace for reduction, and the reduction temperature is controlled between 800 ° C and 1300 ° C between. React in a microwave reduction furnace to obtain coarse sponge iron pellets, that is, semi-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com