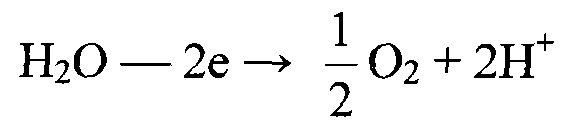

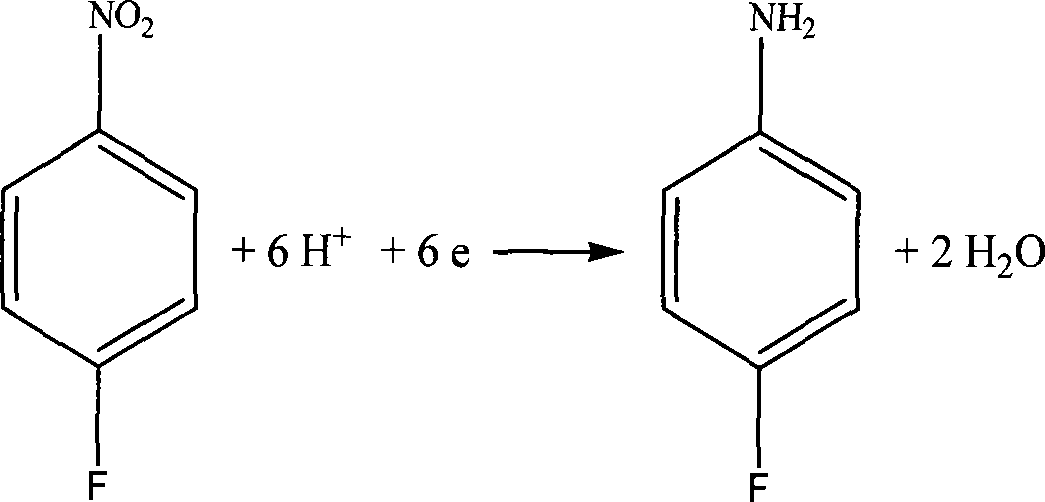

Technical method for synthesizing 4-fluoroaniline by electrochemistry method

A p-fluoroaniline and electrochemical technology, applied in the field of electrochemical synthesis of p-fluoroaniline, can solve the problems of many by-products, difficult separation, complex composition of electrolyte, etc., and achieve the effects of saving consumption and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

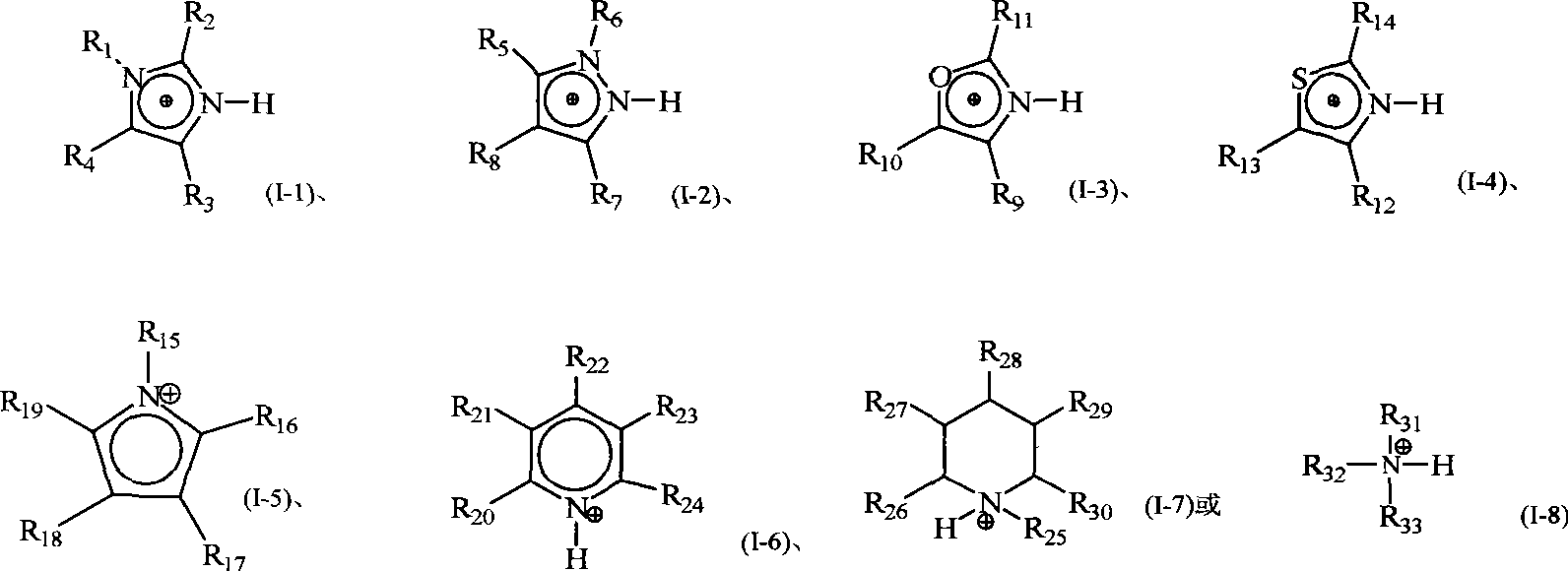

Method used

Image

Examples

Embodiment 1

[0057] In a two-chamber electrolytic cell with each chamber being 100mL, the anode chamber is filled with H at a concentration of 30%. 2 SO 4 Solution, 5% p-fluoronitrobenzene, 1-methyl-3-butylimidazolium tetrafluoroborate, and 10% water were added to the cathode chamber. Both anode and cathode are graphite. The cation exchange membrane is PE-100 type cation exchange membrane. Apply direct current between the cathode and anode for electrolysis. After the reaction was completed, the catholyte was extracted with ether to separate aniline. The cathode current efficiency is greater than 90%. The yield of p-fluoroaniline is greater than 98%.

Embodiment 2

[0059] In a two-chamber electrolytic cell with each chamber being 100mL, the anode chamber is filled with H at a concentration of 30%. 2 SO 4 Solution, 5% p-fluoronitrobenzene, 1-methyl-3-ethylimidazolium tetrafluoroborate, and 10% water were added to the cathode chamber. Both anode and cathode are graphite. The cation exchange membrane is PE-100 type cation exchange membrane. Apply direct current between the cathode and anode for electrolysis. After the reaction is finished, the catholyte is extracted with ether to separate aniline. The cathode current efficiency is greater than 90%. The yield of p-fluoroaniline is greater than 98%.

Embodiment 3

[0061] In a two-chamber electrolytic cell with each chamber being 100mL, the anode chamber is filled with H at a concentration of 30%. 2 SO 4 Solution, 5% p-fluoronitrobenzene, 1-methyl-3-butylimidazolium hexafluorophosphate, and 2% water were added to the cathode chamber. Both anode and cathode are graphite. The cation exchange membrane is PE-100 type cation exchange membrane. Apply direct current between the cathode and anode for electrolysis. After the reaction was completed, the catholyte was extracted with ether to separate aniline. The cathode current efficiency is greater than 90%. The yield of p-fluoroaniline is greater than 95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com