Multiple wavelength outputting ultra-narrow wire single frequency optical fiber laser

A fiber laser and ultra-narrow linewidth technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as difficult high power and single-frequency lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

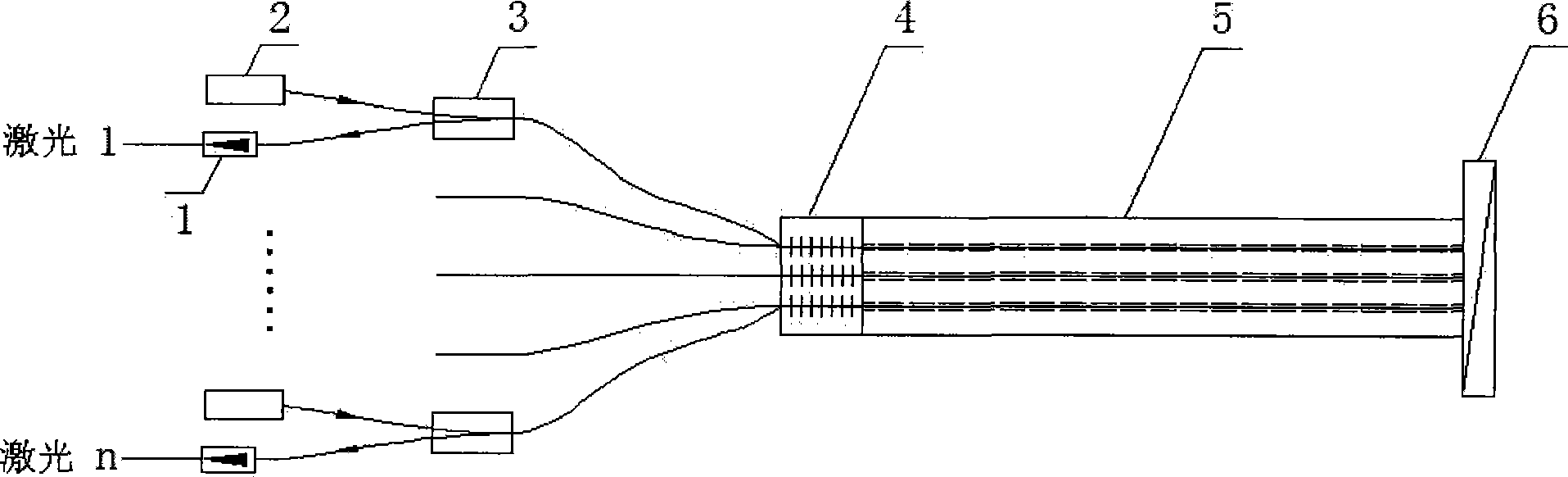

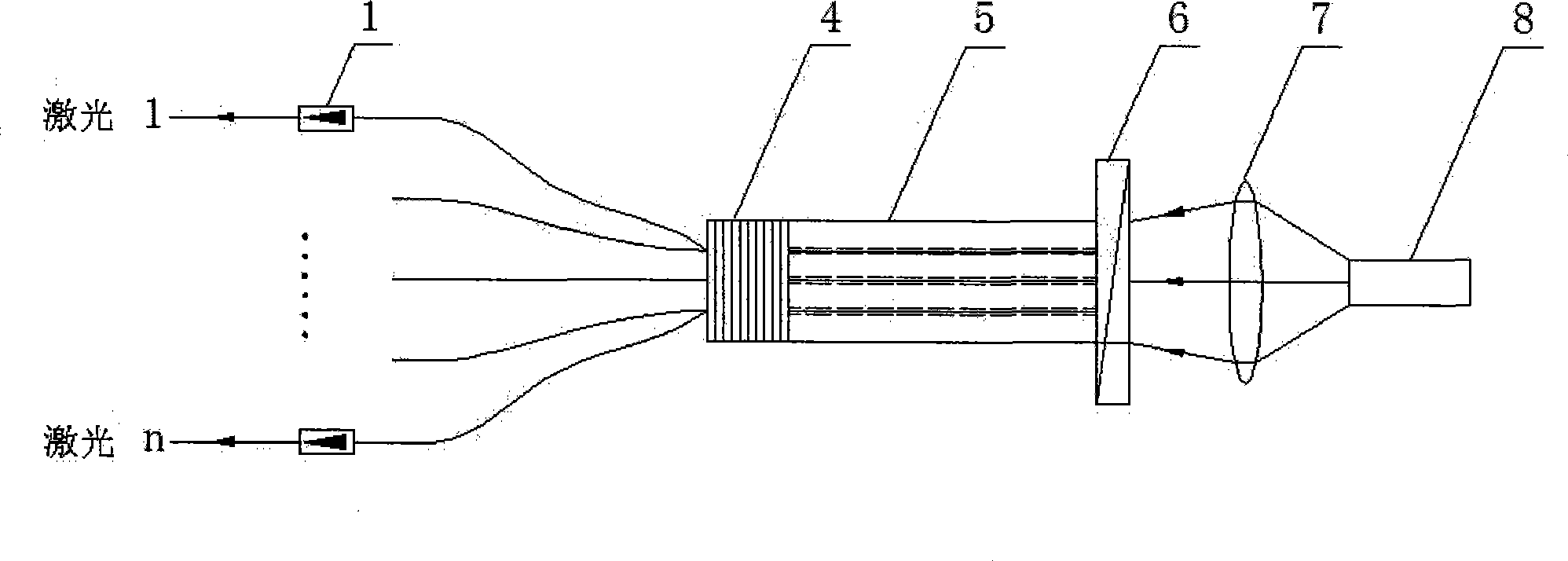

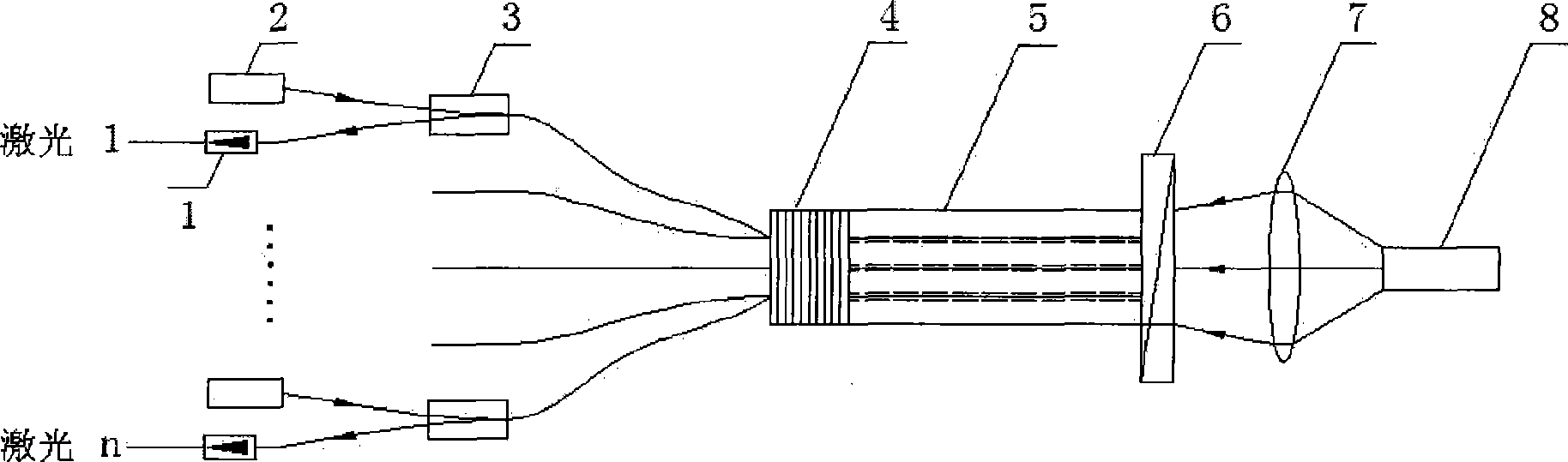

Embodiment 1

[0030] Figure 1-3 It is a schematic diagram of the principle of an ultra-narrow linewidth single-frequency fiber laser with multi-wavelength output in Embodiment 1 of the present invention. A high-gain double-clad two-dimensional array fiber 5 is used as the gain medium of the laser, and is composed of a narrow-band fiber grating array 4 and a dichromatic mirror. 6 constitute the front and rear cavity mirrors of the short F-P cavity structure, the central reflection wavelength of each narrowband fiber grating in the narrowband fiber grating array 4 is located in the gain spectrum of the laser medium, and is located in the high reflection spectrum of the dichromatic mirror 6, the reflectivity Greater than 90%. The pumping light is coupled by the pump end of the wavelength division multiplexer 3 using a single-mode LD 2 forward pumping mode ( figure 1 ), the multimode LD 8 back cladding pump is coupled via the coupling lens 7 ( figure 2 ), or the two-way pump coupling ( im...

Embodiment 2

[0034] Figure 4-6 It is a schematic diagram of the principle of a single-frequency fiber laser with multi-wavelength output in Embodiment 2 of the present invention. A high-gain double-clad two-dimensional array fiber 5 is used as the gain medium of the laser, and is composed of a narrowband fiber grating array 4 and a broadband fiber grating array 9 pairs. Front and rear cavity mirrors with a short F-P cavity structure, wherein the reflection center wavelength of each narrowband fiber grating in the narrowband fiber grating array 4 is within the reflection spectrum of each broadband fiber grating in the corresponding fiber grating array 9 . The pumping light is coupled by the pump end of the wavelength division multiplexer 3 using a single-mode LD 2 forward pumping mode ( Figure 4 ), single-mode LD 2 backward direct pumping ( Figure 5 ), or the two-way pump coupling ( Figure 6 ) into the array core in the laser cavity, its highly doped rare earth particles are reversed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com