Double-enzyme extraction method of tea protein

An extraction method and protease technology, applied in protein food processing, plant protein processing, protein food ingredients, etc., can solve problems such as toxicity, change the nutritional properties of tea protein, and nutrient loss, achieve simple process flow and improve technical level. , the effect of easy control of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

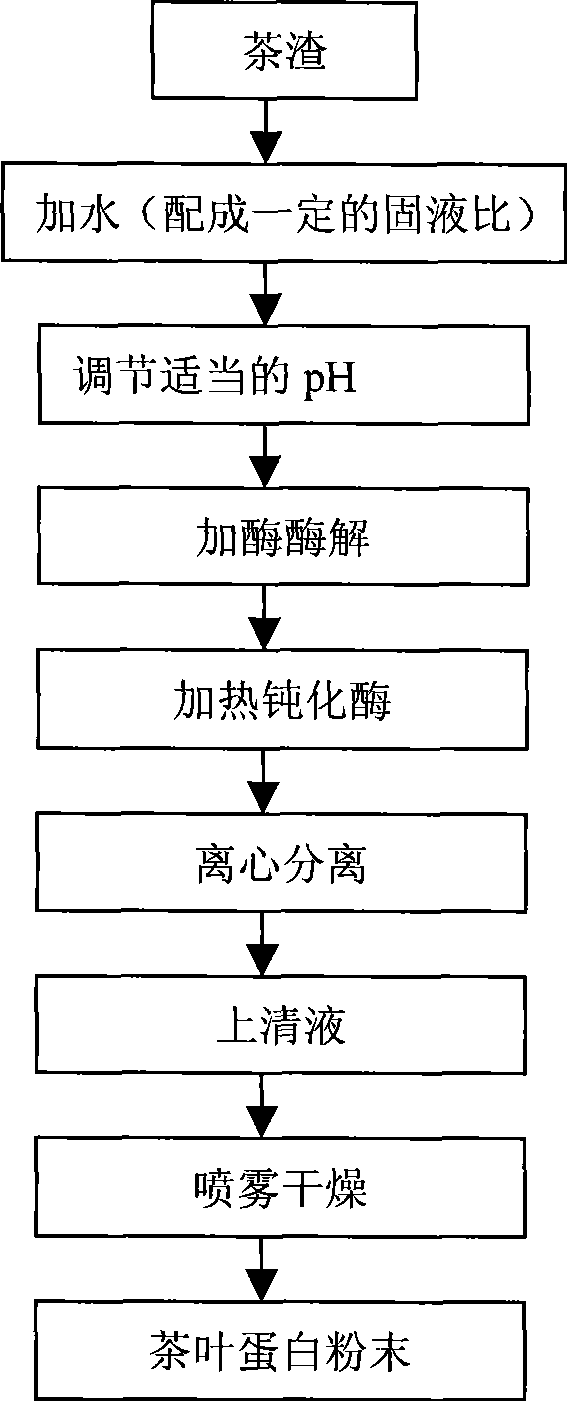

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, a kind of double-enzyme extraction method of tea protein, carries out following steps successively:

[0040] 1), material selection: take dry 1kg tea dregs (moisture content ≤ 9%) as raw material; the protein content in the tea dregs is 23.5%;

[0041] 2), add 30L of clear water to the above 1kg of tea dregs, adjust the pH value to 7.5 with 1.5mol / L NaOH solution; obtain a tea mixture;

[0042] 3) Enzyme extraction: add 20g of alkaline protease to the above tea mixture, keep stirring at 60°C for 3h; then add 10g of compound protease, keep stirring at 60°C for 3h to obtain the extract;

[0043] 4) Inactivate enzyme: heat the extract to 90°C and keep it warm for 1 minute to inactivate the enzyme;

[0044] 5), centrifugation: centrifuge the passivated extract at 4000rpm for 25min, and collect the supernatant;

[0045] 6) The supernatant is dried by a spray dryer. The spray drying conditions are: the inlet air temperature is 200°C, the outlet air temperature...

Embodiment 2

[0046] Embodiment 2, a kind of double-enzyme extraction method of tea protein, carries out following steps successively:

[0047] 1), material selection: take dry 1kg tea dregs (moisture content ≤ 9%) as raw material; the protein content in the tea dregs is 23.5%;

[0048] 2), add 35L of clear water to the above 1kg of tea dregs, adjust the pH value to 8.0 with 1mol / L NaOH solution; obtain a tea-water mixture;

[0049] 3) Enzyme extraction: first add 10g of compound protease to the above tea mixture, keep stirring at 60°C for 4h; then add 30g of alkaline protease, keep stirring at 60°C for 4h;

[0050] 4) Inactivate enzyme: heat the extract to 90°C and keep it warm for 2 minutes to inactivate the enzyme;

[0051] 5), centrifugation: centrifuge the passivated extract at 5000rpm for 20min, and collect the supernatant;

[0052]6), the supernatant was dried by a spray drier under the same drying conditions as in Example 1 to obtain 184.1 g of light brown powdery tea protein, the...

Embodiment 3

[0053] Embodiment 3, a kind of double-enzyme extraction method of tea protein, carries out following steps successively:

[0054] 1), material selection: 1kg dry tea powder (moisture content≤9%) is used as raw material; the dry tea powder is locally produced in Hangzhou, and its protein content is 21.7%;

[0055] 2), add 40L of clear water to the above-mentioned 1kg dry tea powder, adjust the pH value to 7.5 with 1mol / L NaOH solution; obtain the tea-water mixture;

[0056] 3) Enzyme extraction: firstly add 7g of compound protease to the above tea mixture, keep stirring at 55°C for 4h; then add 28g of alkaline protease, keep stirring at 55°C for 4h to obtain the extract;

[0057] 4) Enzyme inactivation: heat the extract to 100°C and keep it warm for 1 minute to inactivate the enzyme;

[0058] 5), centrifugation: centrifuge the passivated extract at 5000rpm for 25min, and collect the supernatant;

[0059] 6), the supernatant was dried by a spray drier, and the drying condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| oiliness | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com