Spraying-free high weather resistance anti-scraping PA/PMMA alloy and preparation thereof

A technology with high weather resistance, scratch resistance and spray-free application. It is applied in the field of polymer materials, which can solve the problems of poor scratch resistance, unsatisfactory scratch resistance, and material performance deterioration of PA, and achieve good scratch resistance, Strong shear sensitivity and effect of improving melt strength and fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with embodiment the present invention is described in further detail.

[0057] (1) Take the following raw materials by weight ratio:

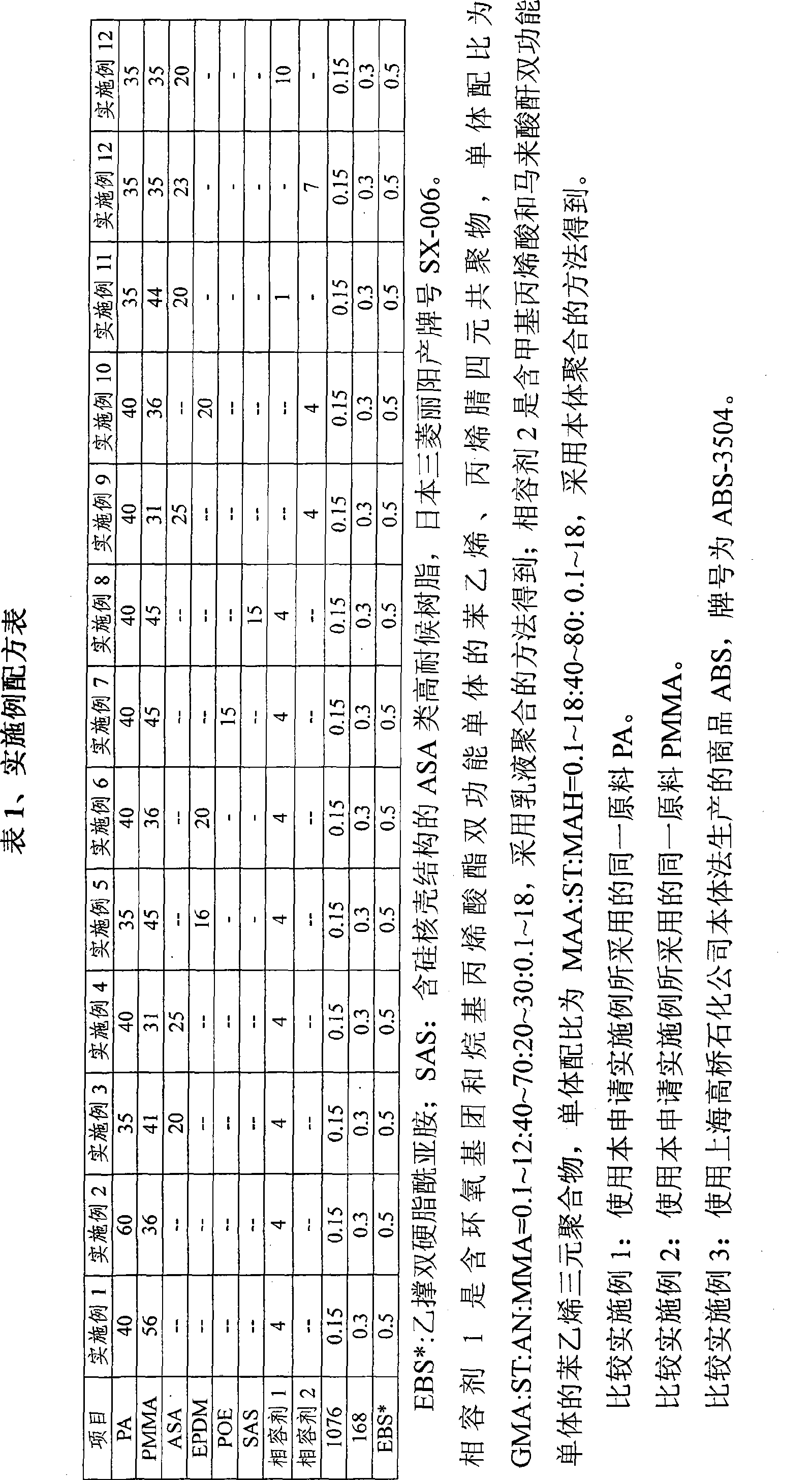

[0058] PA: 20-60%, PMMA: 20-70%, weathering toughening agent ASA, EPDM, SAS, POE: 10-50%, compatibilizer: 1-5%, antioxidant 1076:168=1:2 : 0.1-0.5%, lubricant EBS: 0.1-2.5%, the specific formula sees embodiment (seeing table 1).

[0059] (2) After weighing all the raw materials, put them into a high-speed mixer and mix them at high speed for 1-3 minutes.

[0060] (3) Low-speed discharge.

[0061] (4) Put the mixed raw materials into a twin-screw extruder to extrude and granulate. The rotating speed of the twin-screw machine is 180-600 rpm and the temperature is 170-240°C.

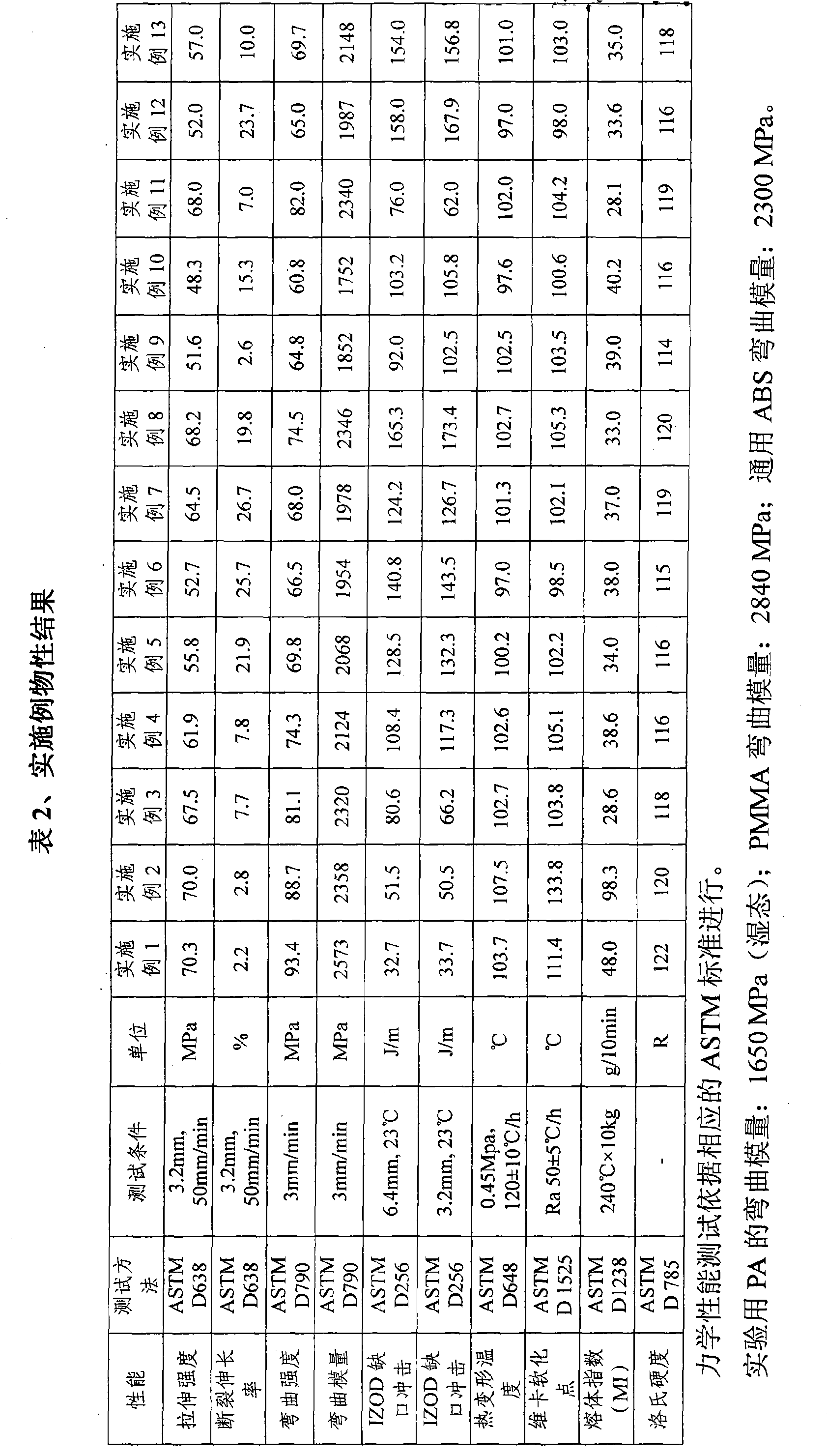

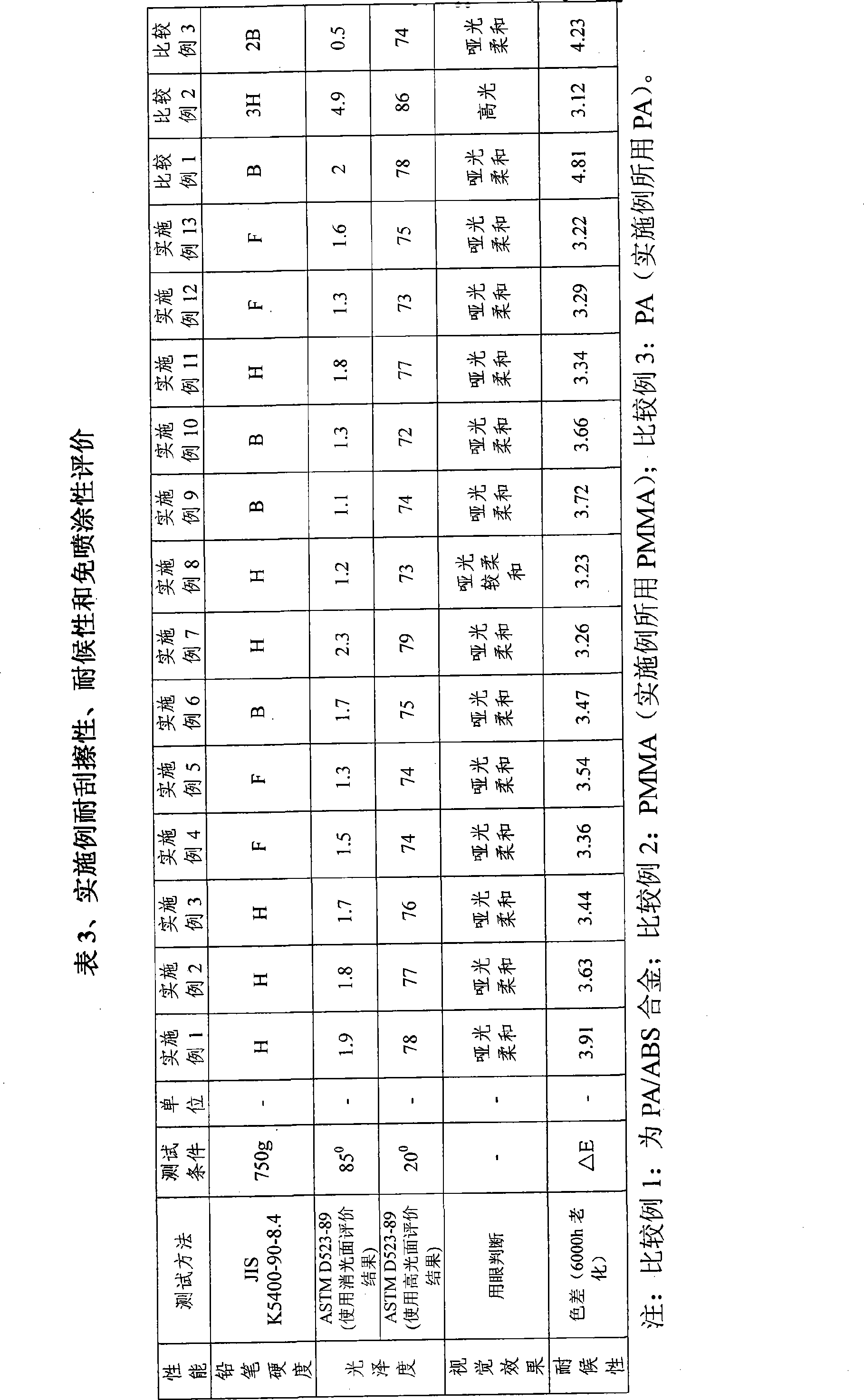

[0062] Implementation results (see Table 2, Table 3).

[0063]

[0064]

[0065]

[0066] The present invention uses the scratch resistance of pencil hardness evaluation material; Use 85 0 Matt surface with 20 0 The glossiness data ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural modulus | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com