Beam deflection and purification apparatus based on random paralleling optimization algorithm

An optimization algorithm and beam deflection technology, applied in optics, optical components, instruments, etc., can solve problems such as difficult application of high-energy lasers and performance limitations, and achieve the effects of simplified system structure, fast response speed, and large dynamic stroke range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

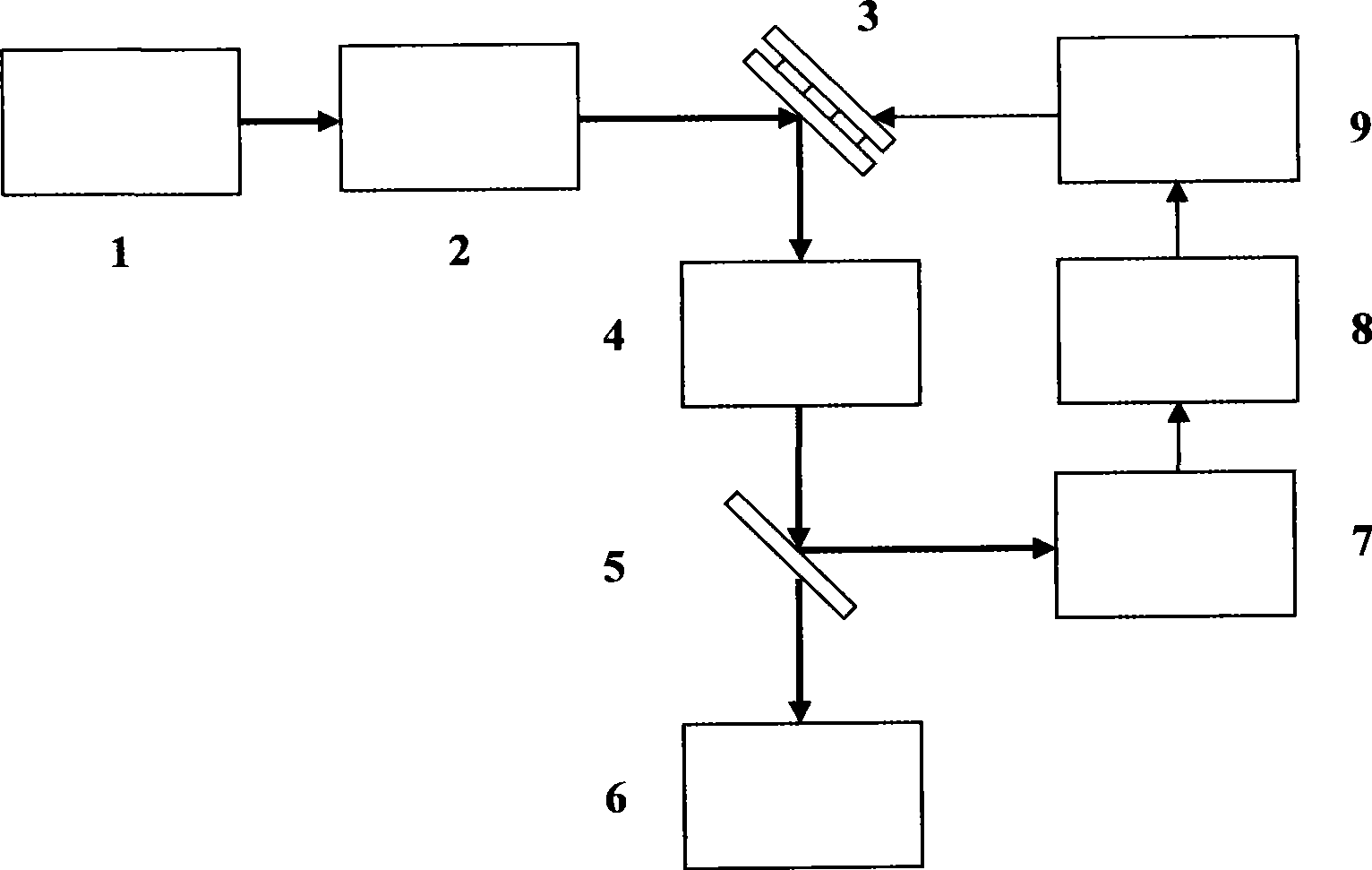

[0013] Such as figure 1 As shown, the whole system includes laser source 1, collimator beam expander system 2, deformable mirror 3, beam shrinker system 4, beam splitter 5, main laser imaging system 6, beam quality evaluation system 7, random parallel optimization algorithm controller 8. Deformable mirror driving unit 9.

[0014] The realization process of the present invention to simultaneously perform beam deflection control and beam purification is as follows:

[0015] The output light of the laser source 1 is expanded to the size of the mirror surface of the deformable mirror 3 through the collimation beam expander system 2, and the deformable mirror 3 reflects the laser beam to the beam shrinking system 4, and the beam shrinking system 4 shrinks the beam to an appropriate size , so that the main laser imaging system 6 imaging device and the detector device of the beam quality evaluation system 7 can be effectively accepted; the beam splitter 5 divides the light into two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com