Liquid dairy produce containing casein phosphoeptides and method for producing the same

A casein phosphopeptide and a production method technology are applied to the liquid milk product containing casein phosphopeptide and the production field thereof, which can solve the influence of the stability of the liquid milk product system, the lack of liquid milk product products, and the inability to bring the product to the market, etc. problem, to achieve the effect of retaining the effective content of CPP, good flavor and perfect formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

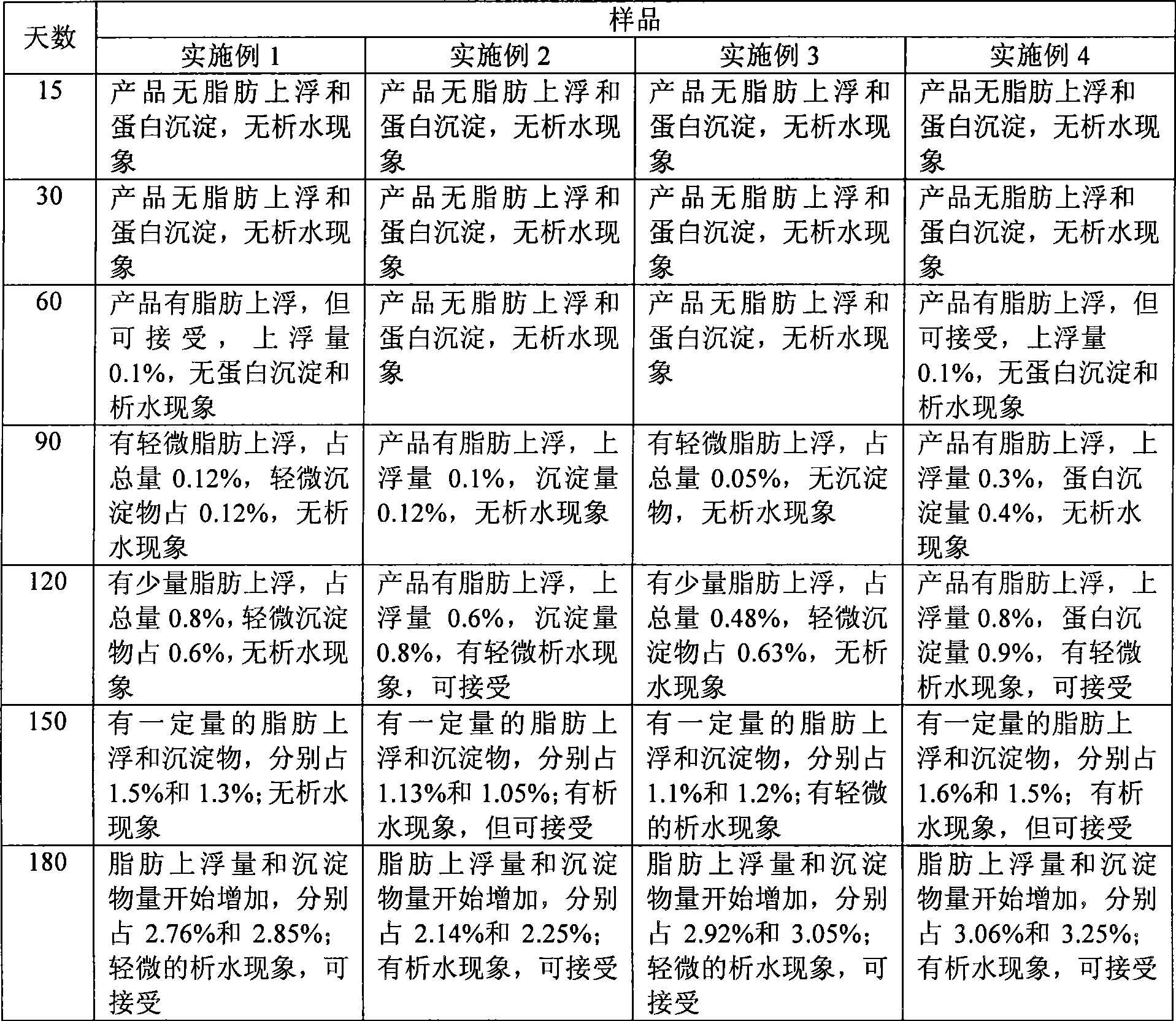

Embodiment 1

[0042] Embodiment 1, sterilized milk containing CPP and production method thereof

[0043] One, prepare the sterilized milk containing CPP of the present embodiment according to the following ratio of raw materials:

[0044] Milk 996.956 parts by weight

[0045] CPP powder 2 parts by weight

[0046] 1 part by weight of monostearic acid ester

[0047] V A , V D Raw material 0.0440 parts by weight.

[0048] Raw material standard:

[0049] Milk: in line with GB6914 standard

[0050] CPP powder: purchased from DMV, model CE900CPP, wherein CPP content ≥ 20%

[0051] V A , V D Raw material: purchased from DSM (DSM) company

[0052]The performance indicators of each raw material meet the requirements of relevant quality standards.

[0053] Two, the production method of the liquid milk product of the present embodiment comprises the following steps successively:

[0054] (1) The raw milk whose temperature does not exceed 8°C is removed through the milk cleaning process, an...

Embodiment 2

[0059] Embodiment 2, low-lactose milk beverage containing CPP and its preparation method

[0060] One, prepare the liquid milk containing CPP of the present embodiment according to the following ratio of raw materials:

[0061] Milk 600 parts by weight

[0062] CPP powder 2 parts by weight

[0063] 1 part by weight of sucrose fatty acid ester

[0064] Carrageenan 0.2 parts by weight

[0065] Lactase 1 part by weight

[0066] V A , V D Raw material 0.0440 parts by weight

[0067] Water 395.756 parts by weight.

[0068] Raw material standard:

[0069] Milk: in line with GB6914 standard

[0070] CPP powder: with embodiment 1

[0071] V A , V D Raw material: with embodiment 1

[0072] Lactase preparation: purchased from DSM Company, commodity model LG1000

[0073] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0074] Two, the production method of the low-lactose milk beverage containing CPP of the present embod...

Embodiment 3

[0081] Embodiment 3, acidic milk drink containing CPP and production method thereof

[0082] One, prepare the acidic milk drink containing CPP of the present embodiment according to the following ratio of raw materials:

[0083] 350 parts by weight of milk, 1 part by weight of CPP powder, 1.2 parts by weight of sodium carboxymethylcellulose, 1 part by weight of lactic acid, 2.5 parts by weight of citric acid, 0.5 parts by weight of food flavor, 50 parts by weight of white granulated sugar, and 593.8 parts by weight of water.

[0084] Raw material standard:

[0085] Milk: in line with GB6914 standard

[0086] CPP powder: with embodiment 1

[0087] The performance indicators of each raw material meet the requirements of relevant quality standards.

[0088] Two, the production method of the acidic milk beverage containing CPP of the present embodiment comprises the following steps successively:

[0089] (1) Remove the mechanical impurities in the raw milk whose temperature do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com