Interface booster type non-nozzle electrofluid mechanics method and use thereof

A nozzle-less, power-assisted technology, which is applied to chemical instruments and methods, methods for granulating raw materials, devices for coating liquids on surfaces, etc., can solve problems such as small power-assisted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

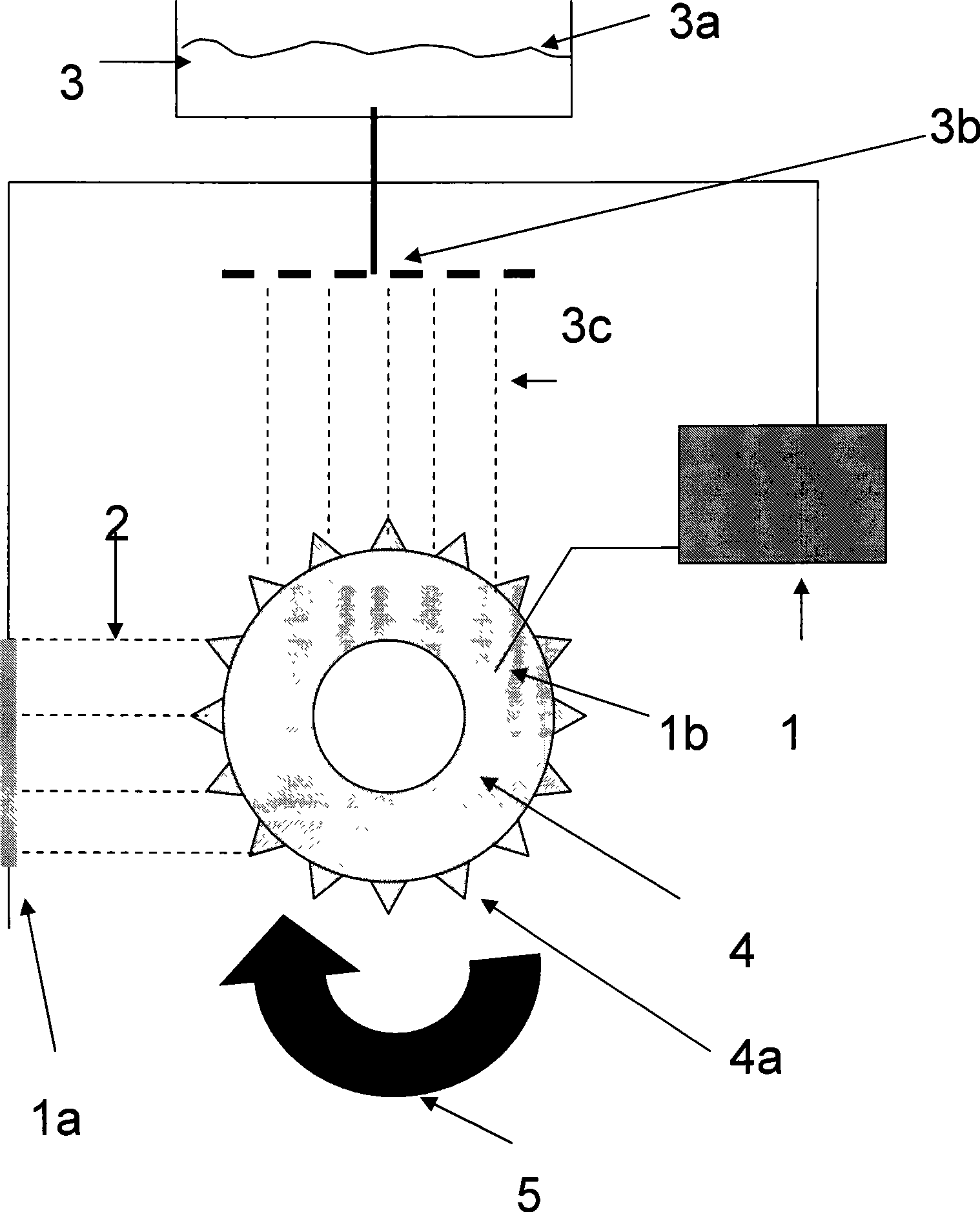

[0067] The electrohydrodynamic method of the centrifugal force electrohydrodynamic method of spraying the processed material without nozzles such as figure 1 shown. The processed material 3, that is, 22% polystyrene ethyl acetate solution with an average molecular weight of 15.8k Dalton, is sprayed onto the roller 4 through the processed material shower assembly 3b, that is, a row of shower pipes. When the roller rotates at 1000 When rotating at a speed of 1 / min, the sprayed processed material 3c is subjected to centrifugal force by the sharp protrusion 4a on the edge of the roller. The roller is connected to the positive pole of the 30,000-volt positive high-voltage power supply 1 as the working electrode 1b, and the counter electrode is combined with the collecting device 1a, that is, the collecting plate. When a high-voltage electric field is applied and the roller rotates, the material 3 to be processed is simultaneously subjected to centrifugal force and electrostatic fo...

Embodiment 2

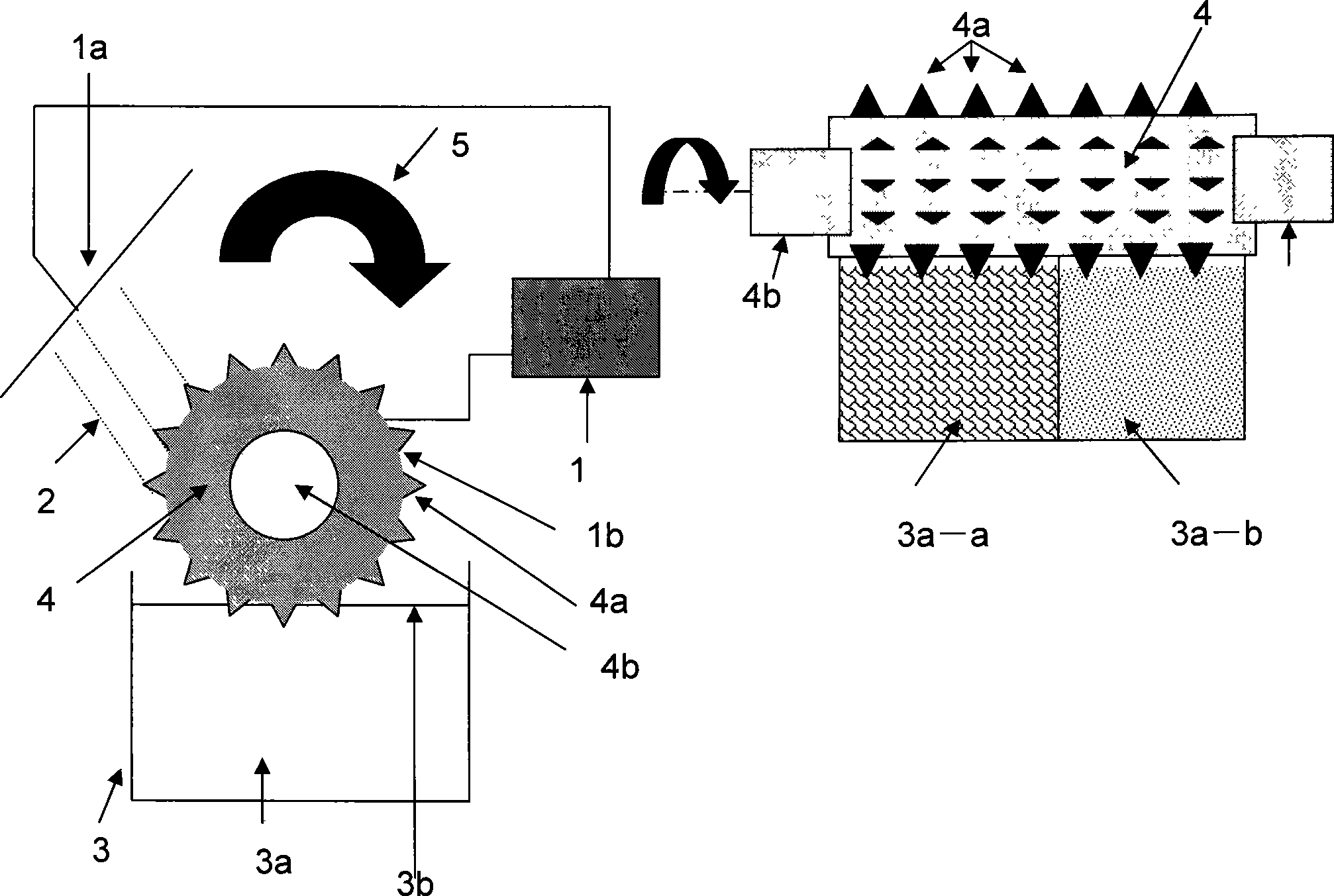

[0069] The roller impact electrohydrodynamic method of the material to be processed without nozzle is as follows: figure 2 Department shown. Fluidized processed materials 3a-a are 12% (mass fraction) polylactic acid acetone solution with a weight average molecular weight of about 150,000 and 3a-b are silver-loaded zeolites with a concentration of 20% W / V and a particle size of 100 nanometers 10% polyvinyl alcohol aqueous solution with an average molecular weight of 80,000 is located in the container 3 below the roller, and when the roller 4 rotates at a speed of 1000 rpm, the material to be processed is attached to the roller, and is subjected to centrifugation at the sharp protrusion 4a on the edge of the roller. force. The roller is connected to the negative pole of the 30,000-volt negative high-voltage power supply 1 as the working electrode 1b, and the counter electrode is combined with the collecting device 1a, that is, the collecting plate. When a high-voltage electri...

Embodiment 3

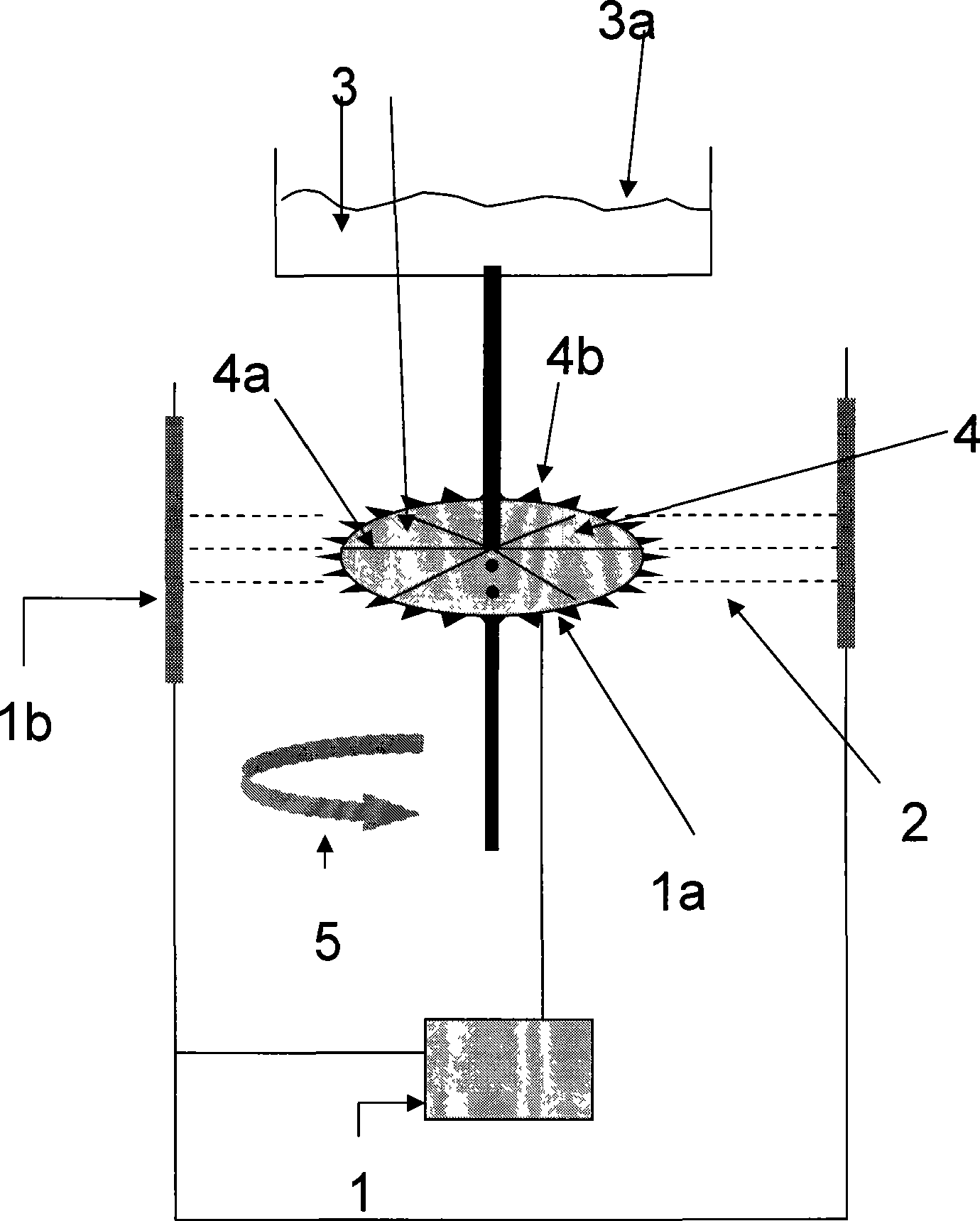

[0071] The system structure of centrifugal force electrohydrodynamic method without nozzle turntable is as follows: image 3 shown. The fluidized processed material 3, that is, the 10% polycaprolactone tetrahydrofuran solution with an average molecular weight of 120,000 and a concentration of 0.2% by weight of the tricalcium phosphate powder material with an average particle diameter of 300 nanometers is guided to the turntable 4 When the turntable rotates at a speed of 1000 rpm, the material to be processed follows the guide groove 4a on the turntable to the sharp protrusion 4b on the edge of the turntable to obtain centrifugal force. Connect the turntable to the negative pole of the 30,000-volt negative high-voltage power supply 1 as the working electrode 1b, and the counter electrode is combined with the collecting device 1a, that is, the collecting plate. When a high-voltage electric field is applied and the turntable rotates, the material 3 to be processed is simultaneou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com