Production method for ternary ferroelectric polymer thin-film material

A technology of ferroelectric polymers and ternary polymers, which is applied to fixed capacitance parts, thin film/thick film capacitors, stacked capacitors, etc., and can solve problems such as unclear origin mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Preparation of P(VDF-TrFE-CFE) ternary ferroelectric polymer precursor solution

[0020] Weigh 0.01g terpolymer P (60%VDF-33%TrFE-7%CFE) in a 250ml flask, add 100ml dimethyl sulfoxide, stir at 60°C for 3 hours, leave it for 24 hours, wait use.

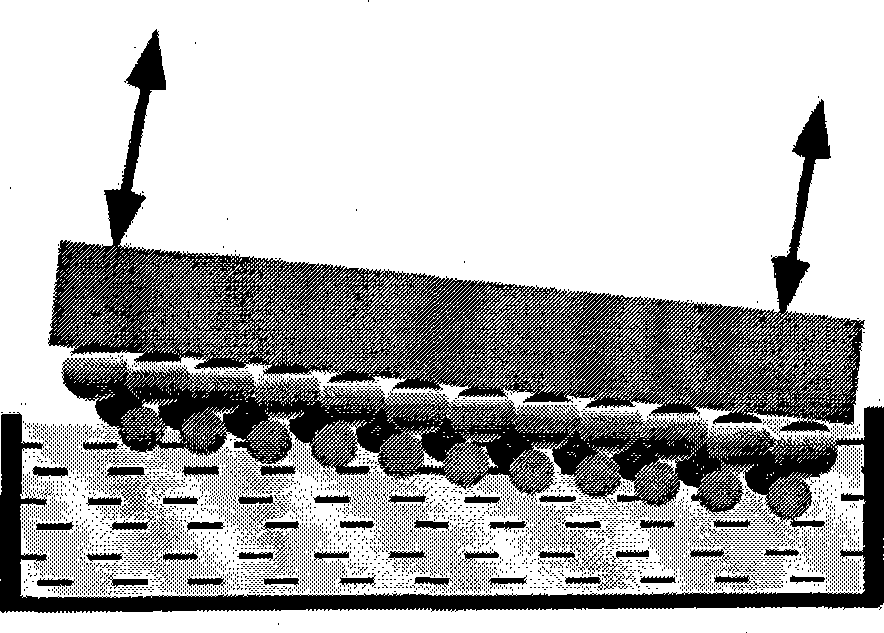

[0021] 2. Horizontal growth of ternary ferroelectric polymer LB films

[0022] Take 4ml of the precursor solution with a syringe, and then evenly drop it in the deionized water tank of the Nima311D LB film growth system. After standing for 1 hour, make the side of the glass substrate with the metal Al electrode layer and the surface of the deionized water float The precursor solution was contacted, and the film was horizontally transferred to the Al electrode layer under the surface pressure of 5mN / m, and pulled repeatedly for 30 times, and then the film was placed in an oven and annealed at 125°C for 5 hours, and finally the thickness of the film was 40-50nm. In between, evaporate the Al film on it as the upper electrode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com