Stuffing with wing veins for biological treatment of exhaust gas

A technology for biological treatment and waste gas, applied in sustainable biological treatment, biological water/sewage treatment, chemical/physical processes, etc., can solve the problems of difficult biofilm blockage, microbial film hanging easily, and high pollution load, and achieve easy film hanging. , the effect of large biomass and high pollution load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

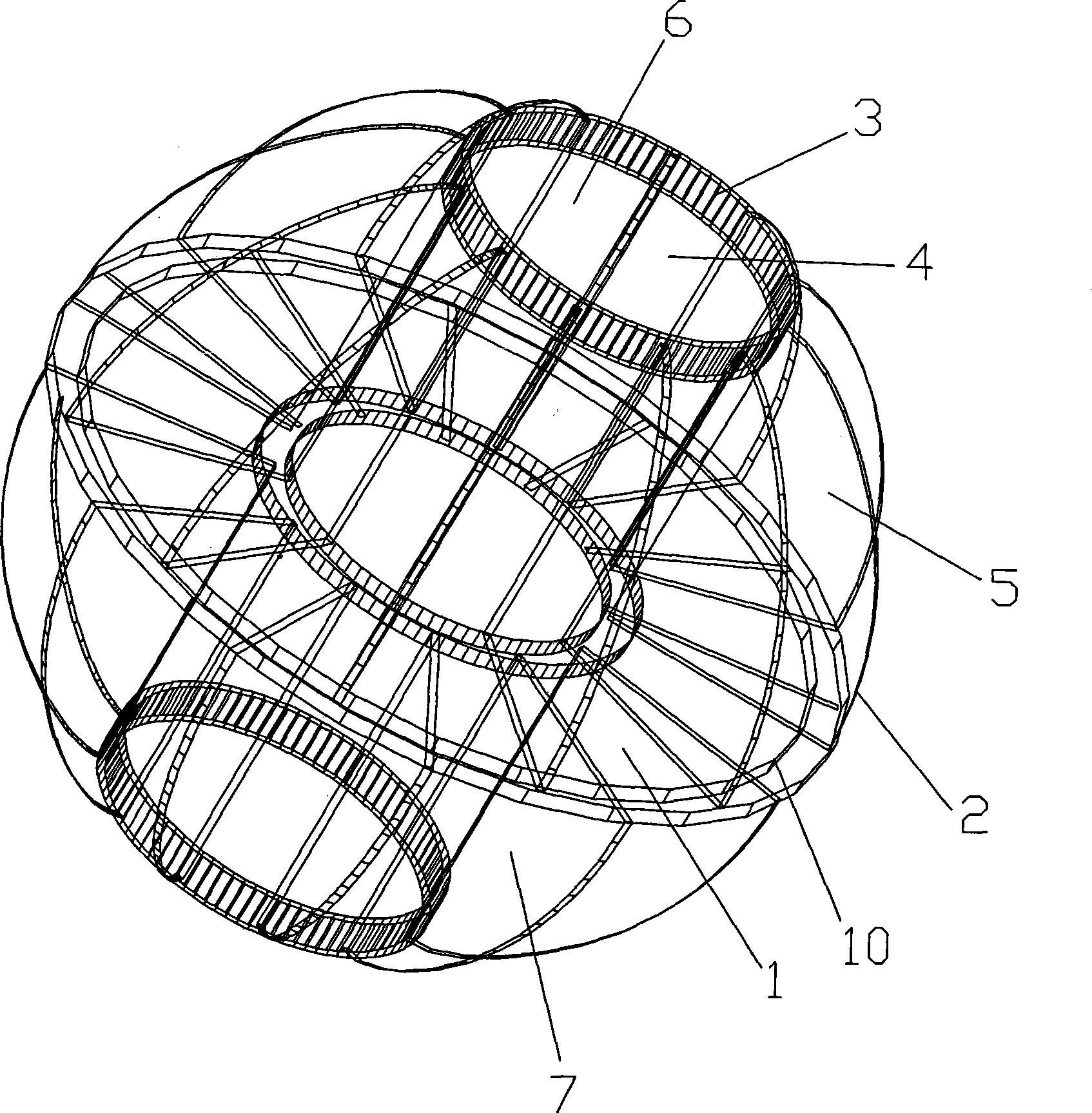

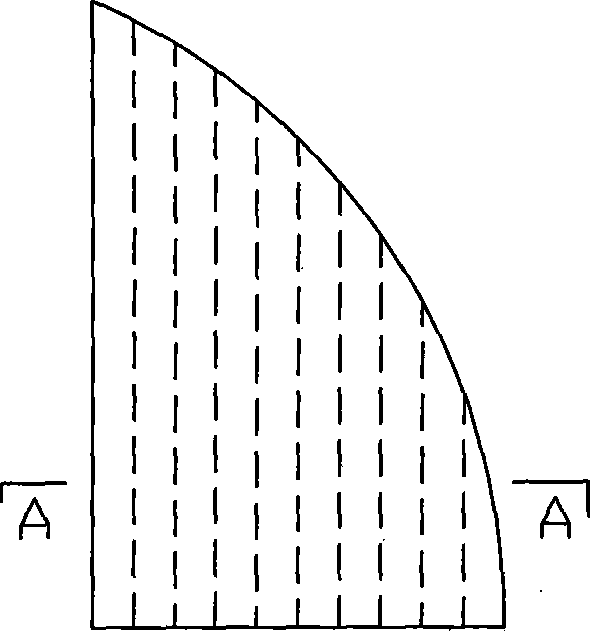

[0034] refer to Figure 1-3 : A kind of corrugated multi-faceted ball filler for waste gas biological treatment, the filler is surrounded by two hemispheres to form a grid body whose outer contour surface is a spherical surface, the butt surface of the two hemispheres constitutes the equatorial plane 1, and the equatorial plane 1 The outer ring is the equatorial ring 2; each of the hemispheres is provided with a latitude ring 3 parallel to the equatorial ring 2, and the plane where the latitude ring 3 is located is the latitude plane 4, between adjacent latitude planes 4 or the equatorial plane 1 Between the adjacent latitudinal planes 4 are connected blades 5 divergently distributed around the axis of the hemisphere, and the edges of the blades 5 are supported between adjacent latitudinal planes 4 or between the equatorial plane 1 and its adjacent latitudinal planes 4 , the outer arc edge forms the outer contour line of the sphere, and the grid unit 7 is formed between the ad...

Embodiment 2

[0057] refer to Figure 4-6 : A corrugated wing multi-face column filler for waste gas biological treatment, the filler is composed of an upper column 8 and a lower column 9. The outer contour surface is a cylindrical grid body, and the butt surface of the upper column and the lower column Constitute the equatorial plane 1, the outer ring of the equatorial plane 1 is the equatorial ring 2; one of the upper and lower cylinders is provided with at least one latitude ring 3 parallel to the equatorial ring 2, and the plane where the latitude ring 3 is located is the latitude plane 4. Between the adjacent latitude planes 4 or between the equatorial plane 1 and its adjacent latitude plane 4, there are blades 5 divergently distributed around the axis, and the edges of the blades 5 are supported between the adjacent latitude planes 4 or the equator Between the surface 1 and its adjacent latitude surface 4, its outer edge constitutes a cylindrical side, and a grid unit 7 is formed betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com