Lactobacillus casei capable of reducing beta-lactoglobulin antigen antigenicity in cow's milk and use thereof

A technology of Lactobacillus casei and lactoglobulin, which is applied in the application field of Lactobacillus casei, can solve the problems of reducing milk allergy, affecting the nutritional and sensory properties of cow milk, and the influence mechanism of allergy and flavor being unclear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Embodiment 1, the cultivation mode of Lactobacillus casei WPC09 of the present invention

[0051] (i) Strain activation: the original strain of Lactobacillus casei WPC09 was inoculated in MRS liquid medium, and activated by culturing at 37° C. for 12-16 h, and activated continuously for two generations.

[0052] (ii) Seed culture: After activation, Lactobacillus casei WPC09 is inoculated in 11% (w / v) skim milk sterilized at 110°C for 10 minutes, cultured at 37°C for 14-16h until curdling, continuous culture activation Two generations, used as mother starter.

[0053] (iii) Fermentation culture: Lactobacillus casei WPC09 was inoculated in 11% skim milk with an inoculation amount of 1% (V / V), and cultured at 37° C. for 24 hours.

Embodiment 2

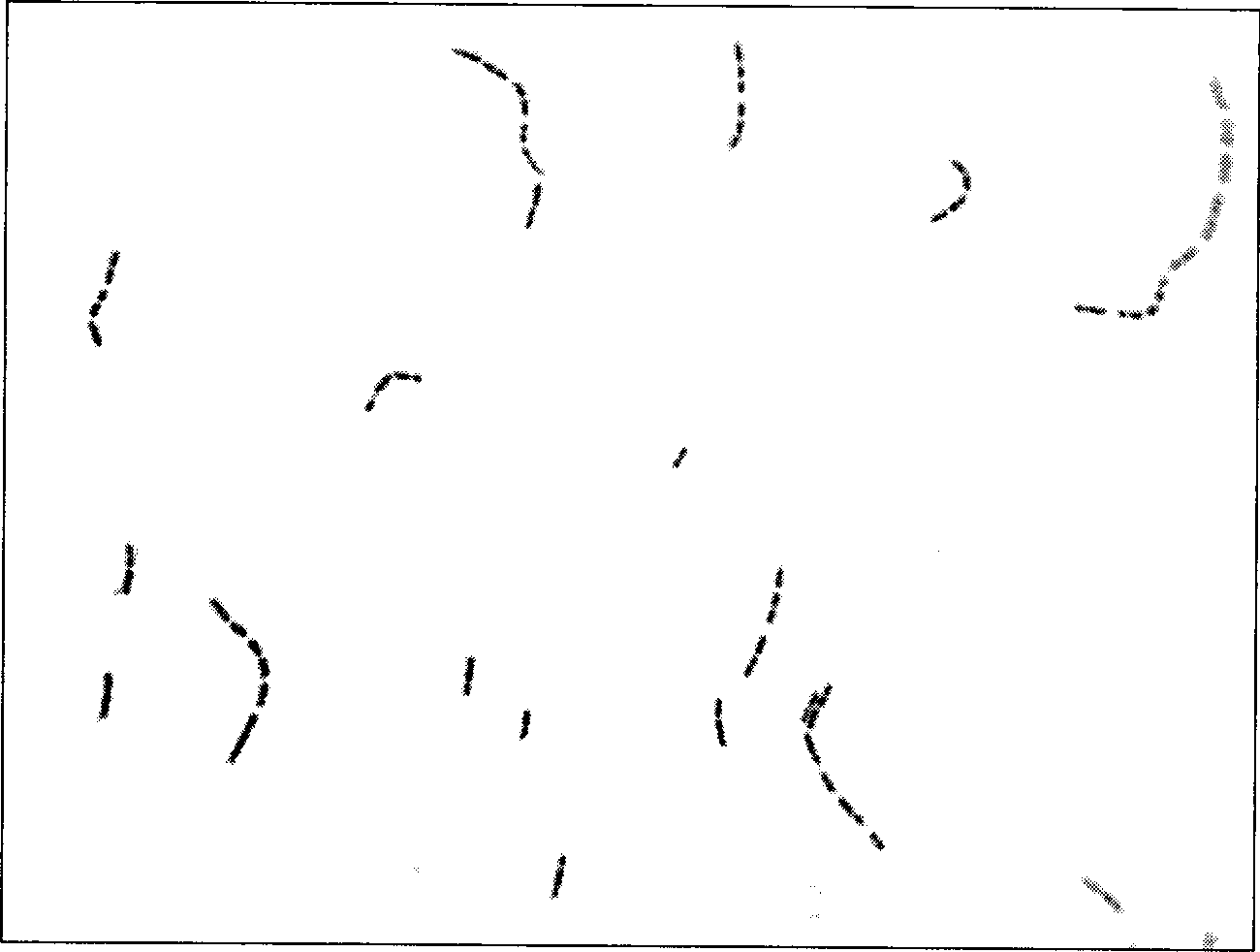

[0054] Embodiment 2, the physiological and biochemical characteristics and strain identification of Lactobacillus casei WPC09 of the present invention Inoculate Lactobacillus casei WPC09 in MRS liquid culture medium (BD Difco company, trade name Lactobacilli MRS Broth), cultured anaerobically at 37°C for 18h, centrifuged to get the thalline, and washed with PBS buffer solution (such as GNB10010 PBS buffer solution produced by Shanghai Water Source Biotechnology Co., Ltd., containing 0.144g KM per liter 2 PO 4 , 9.0g NaCl, 0.795g Na 2 HPO 4 7H 2 (2, pH7.4) was washed twice, inserted into API 50 CHL liquid medium (bio-Mérieux China Co., Ltd., API 50 CHLMedium) to make a bacterial suspension, and inserted into API 50 CH identification reagent strip (bio-Mérieux China Co., Ltd.), anaerobic culture at 37°C for 24h-48h, record the fermentation results of 49 kinds of carbohydrates by the strains, and input them into the identification software API LAB PLUS of Mérieux Company. Th...

Embodiment 3

[0058] The microbiological characteristic of embodiment 3, Lactobacillus casei WPC09

[0059] Lactobacillus casei WPC09 was inserted into MRS liquid medium at 1% (V / V), and cultured statically at 12, 20, 30, 40, 45 and 50°C for 12h, 24h and 48h respectively, and the growth status was observed. Listed in Table 2. The minimum growth temperature of Lactobacillus casei WPC09 is 20°C, and the maximum growth temperature is 45°C. It can grow at room temperature, but not at 12°C.

[0060] Table 2 Growth of Lactobacillus casei WPC09 strain at different temperatures

[0061]

[0062] Note: + means growth, - means no growth

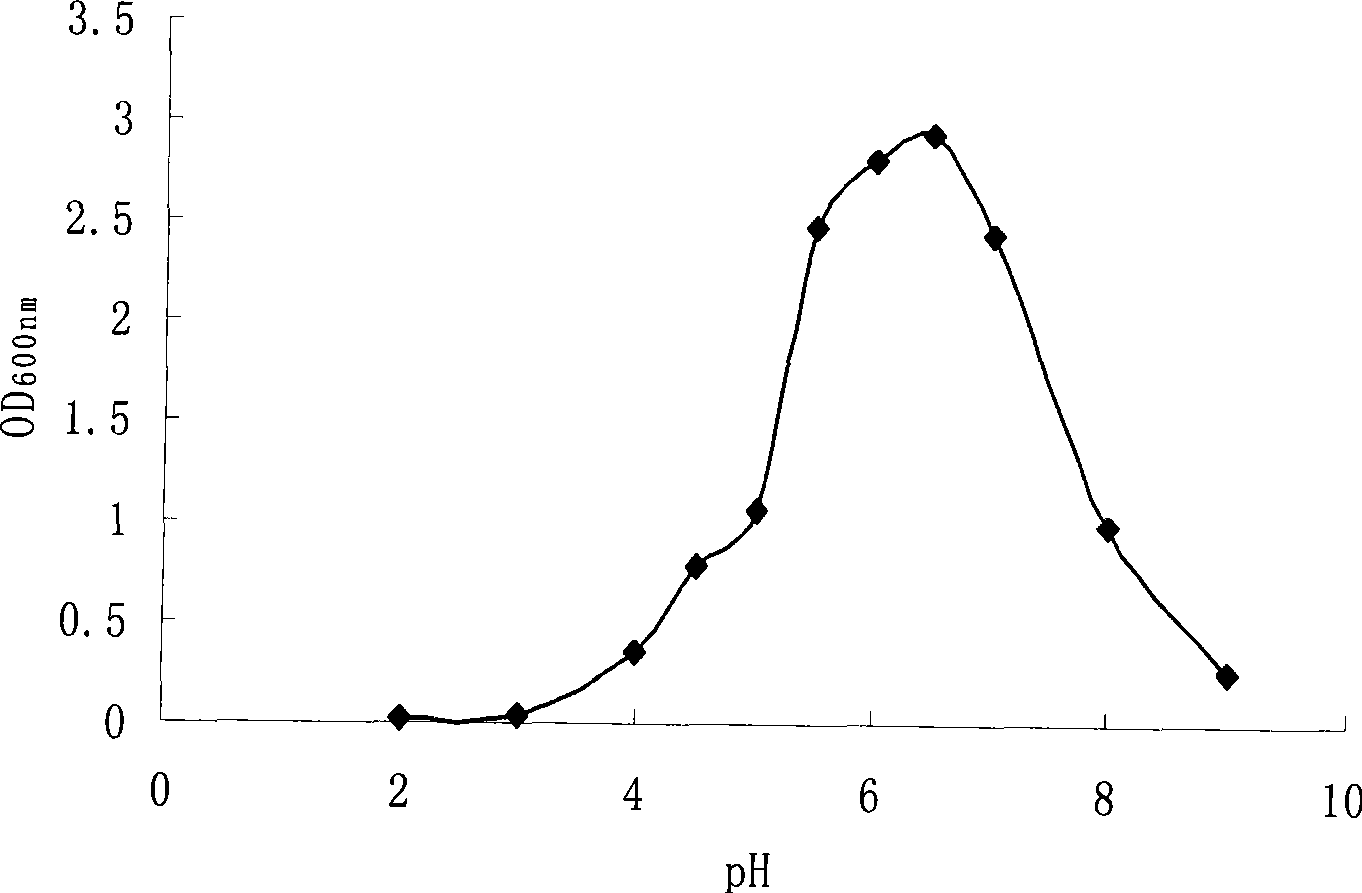

[0063] Insert the Lactobacillus casei WPC09 strain into the MRS liquid medium with different pH values at 1% (V / V), culture it statically at 37°C for 12h, and use the UV2100 ultraviolet spectrometer produced by Unico (Shanghai) Instrument Co., Ltd. Photometer measures the OD value (optical density value) of bacterium liquid at 600nm, observes the optimal gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com