Combined fluidized bed slag cooling apparatus

A technology of slag cooler and fluidized bed, which is applied in the field of cooling treatment of CFB boiler bottom slag, can solve the problems such as difficulty in perfecting the design structure of the air distribution device, obstruction of lateral movement, difficulty in slag discharge, etc., to meet the requirements of continuous slag discharge and Stable combustion conditions, simple gas-solid flow and mixing, and easy automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

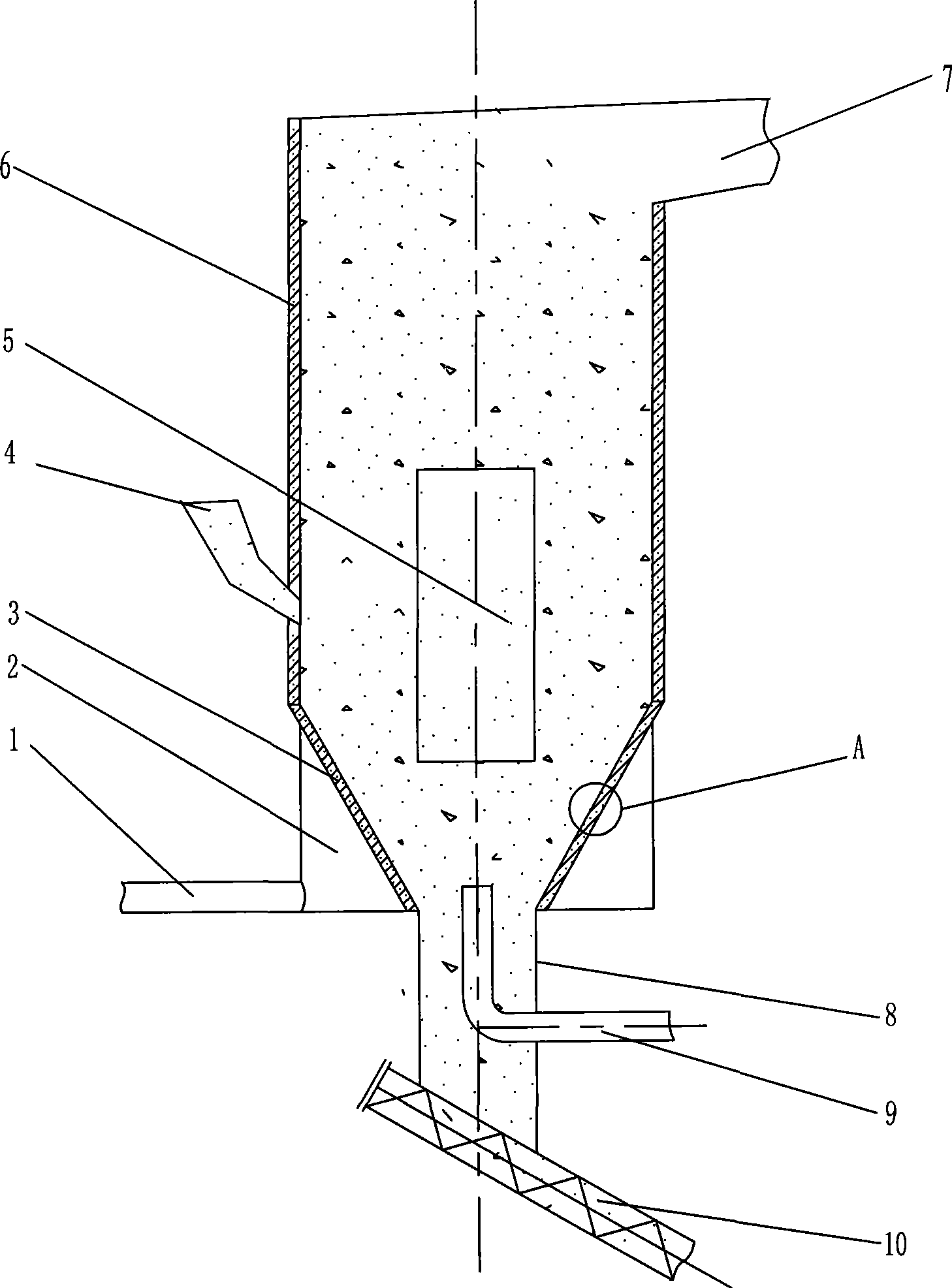

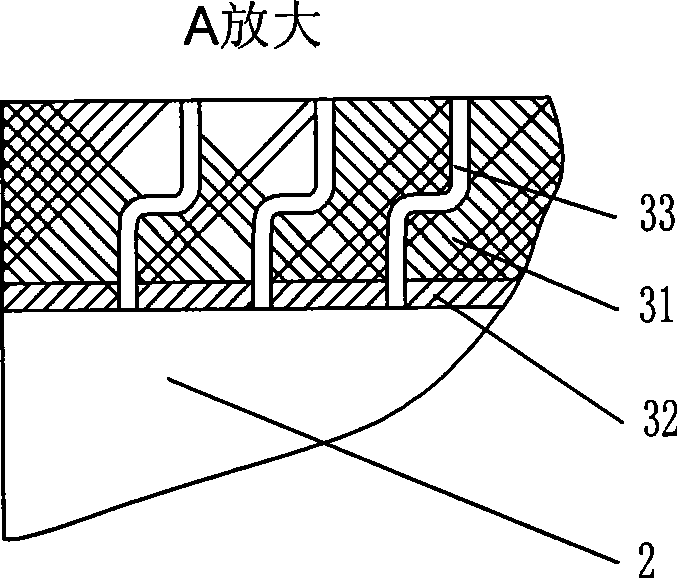

[0025] Such as figure 1 , 2 As shown, a combined fluidized bed slag cooler includes a body 6 , an air chamber 2 , an air distribution device 3 , a slag inlet pipe 4 , a slag discharge pipe 8 , an air inlet pipe 1 , and an air outlet pipe 7 . The body 6 is provided with a slag inlet pipe 4, and the bottom of the body 6 is connected to a slag discharge pipe 8; the lower part of the body 6 is provided with an air distribution device 3 and connected to the air chamber 2 with the air inlet pipe 1; the top of the body 6 is connected to an air pipe 7. In the slag discharge pipe 8, a spray pipe 9 for air intake is arranged.

[0026] Further, a guide pipe 5 is provided above the injection pipe 9 in the body 6 .

[0027] Furthermore, a mechanical slag discharge valve or a conveyor is installed at the outlet of the slag discharge pipe 8 . Conveyor can choose screw conveyor.

[0028] The upper part of the body 6 is a cylinder, and the lower part of the body 6 is a cone with a central ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com