Method for processing phenolic resin phenolic wastewater

A phenolic resin and treatment method technology, applied in water/sewage treatment, water/sewage multi-stage treatment, neutralized water/sewage treatment, etc., can solve the problems of secondary pollution, increase the difficulty of biochemical treatment, etc. Process stability, improve biochemical treatment capacity, and change the effect of serious pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

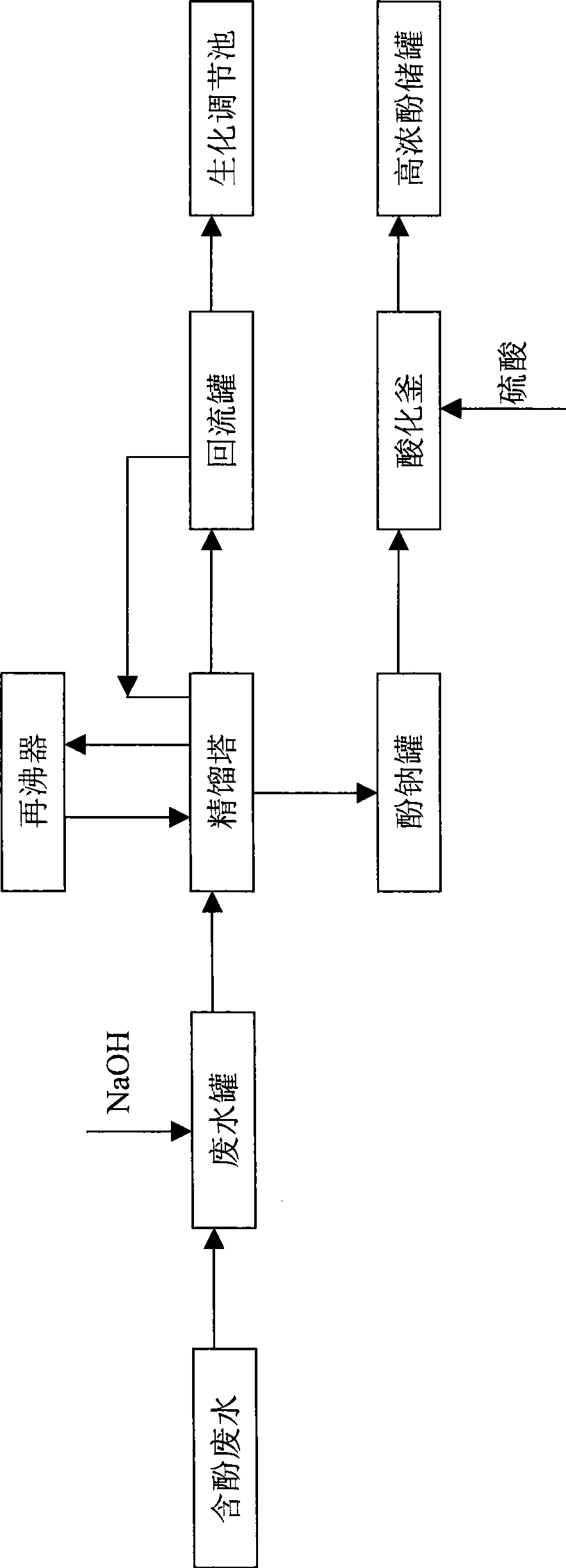

[0015] Such as figure 1 As shown, a large-scale test was carried out through continuous operation in the rectification tower. The production process is to mix the phenol-containing wastewater to be treated (phenol content is 2-5wt%) in the wastewater tank, and take samples to measure the phenol content of the wastewater to be treated. content and pH. Add sodium hydroxide and mix well to adjust the pH value of the wastewater to 11.5-14. The waste water with adjusted pH value is pumped into the rectification tower from the feed port of the rectification tower by vacuum, and the material is heated with hot water through the reboiler, and the initial stage adopts a total reflux state. Start to collect waste water from the top of the rectification tower after the effluent index at the top of the tower is stable, and start collecting sodium phenate when the temperature difference between the bottom and the top of the tower is 7-10°C, and the content of sodium phenate in the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com