Terminal surface pump order variant grade doping composite plate laser amplifier

A laser amplifier, gradient doping technology, applied in lasers, laser parts, phonon exciters, etc., can solve problems such as uneven thermal stress of pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

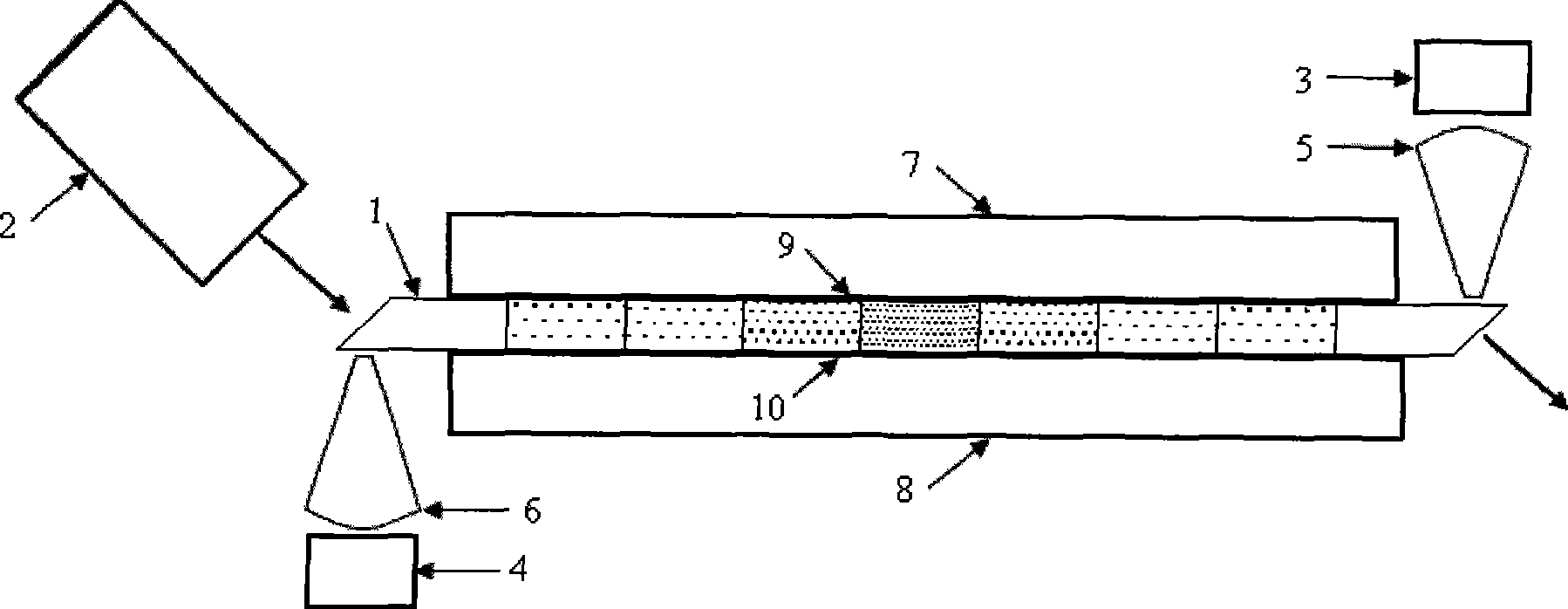

[0038] see first figure 1 , figure 1 It is a block diagram of the overall structure of the end-pumped gradient-doped composite slab laser amplifier of the present invention. It can be seen from the figure that the end-pumped step-change gradient doped composite slab laser amplifier of the present invention includes: laser gain medium 1, seed source 2, pump sources 3, 4, coupling lens conduits 5, 6, and slab cooling heat sink 7, 8, and indium transition layers 9, 10, which are characterized by:

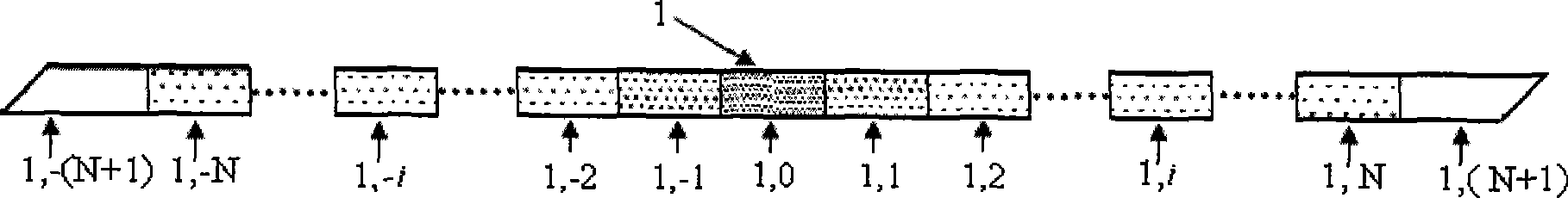

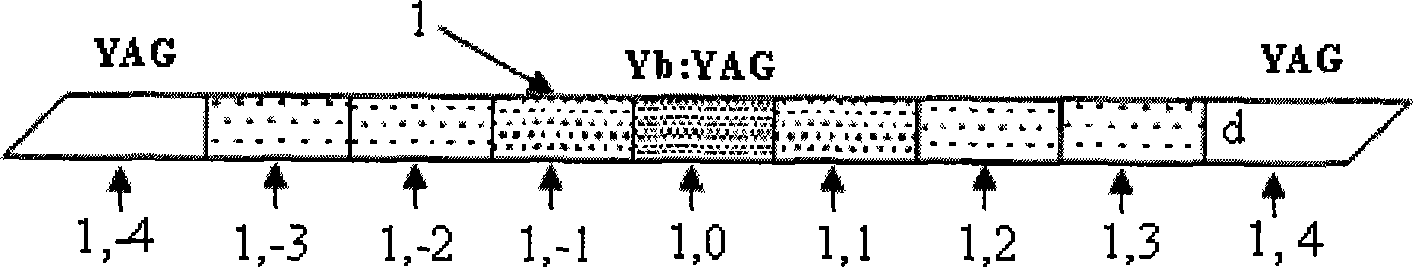

[0039] The laser gain medium 1 is an N-order gradient doped composite ceramic slab, wherein N is a positive integer greater than 1, see figure 2 , in the figure:

[0040] 1, 0 means the 0th order sub-slat,

[0041] 1, ±i means ±i-th order sub-slats, i=1, 2, 3,..., N;

[0042]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com