Solar cells with phase grating nanostructures

A solar cell and phase grating technology, applied in the field of solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with drawings and embodiments.

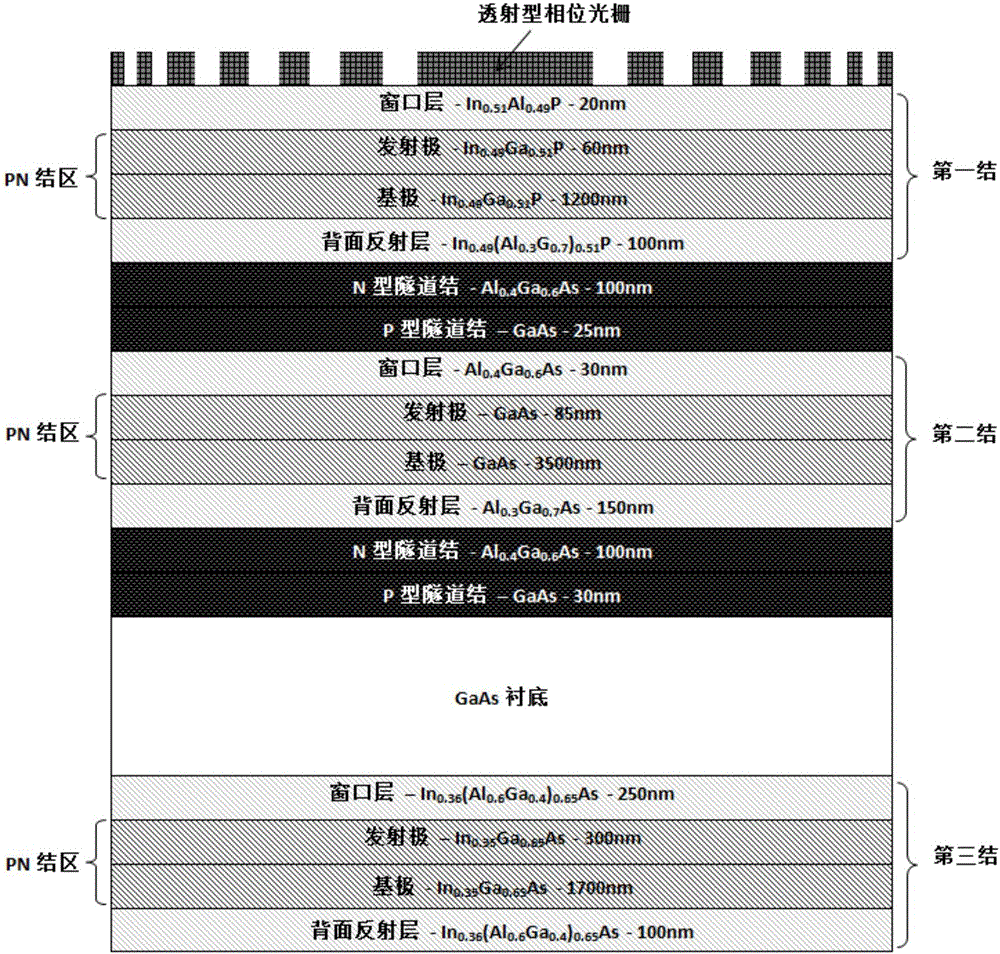

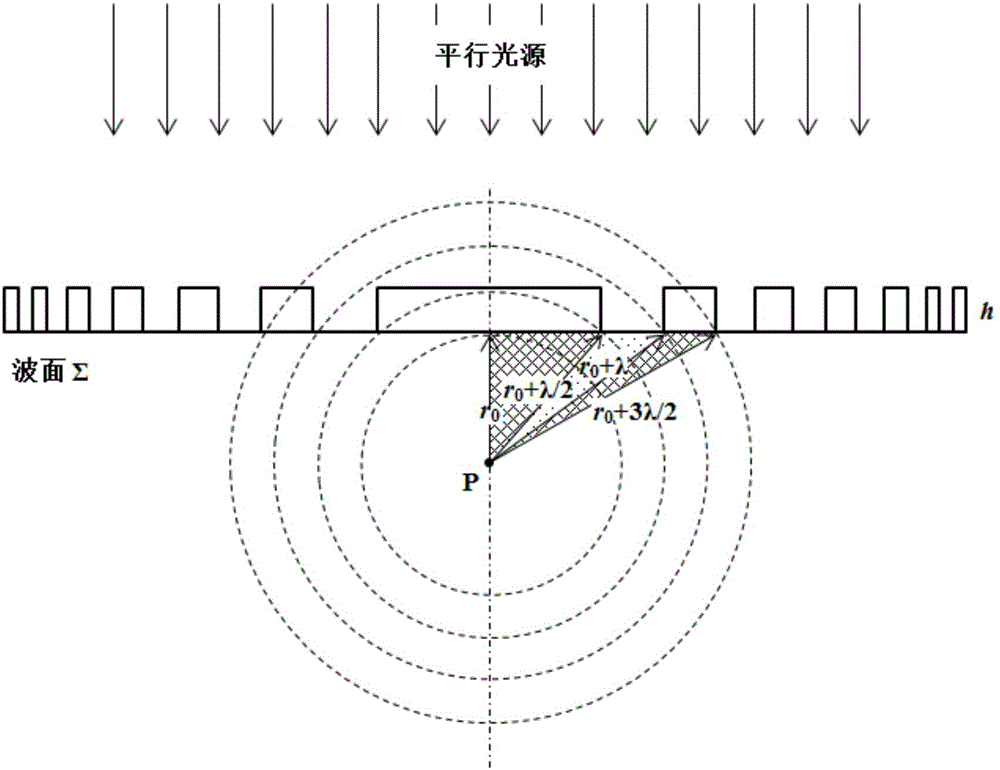

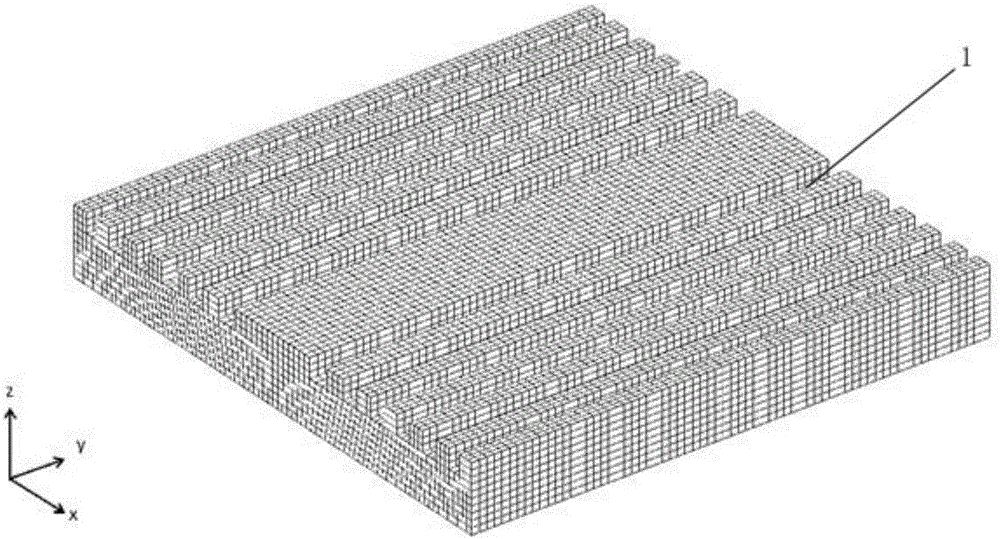

[0043] Such as figure 1 As shown, the present invention includes a solar cell; it is characterized in that: a transmission type phase grating is made on the upper surface of the solar cell, the phase grating is formed by a series of etched grooves, and the depth of the etched groove is given by the formula h=λ / [2(n-1)] is calculated so that the phase difference of the incident light propagating from the upper surface of the grating to the lower surface is π, where λ is the central wavelength of the incident light, and n is the refractive index of the phase grating material on the surface of the solar cell; The width and interval of the etching grooves are designed according to the Huygens-Fresnel principle and calculated by the Fresnel wave band method.

[0044]The depth of the etching groove is 1 / 4 of the central wavelength of the incident light, so that the phase di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com