Edible microcapsule mineral matter nutritive salt and preparation method thereof

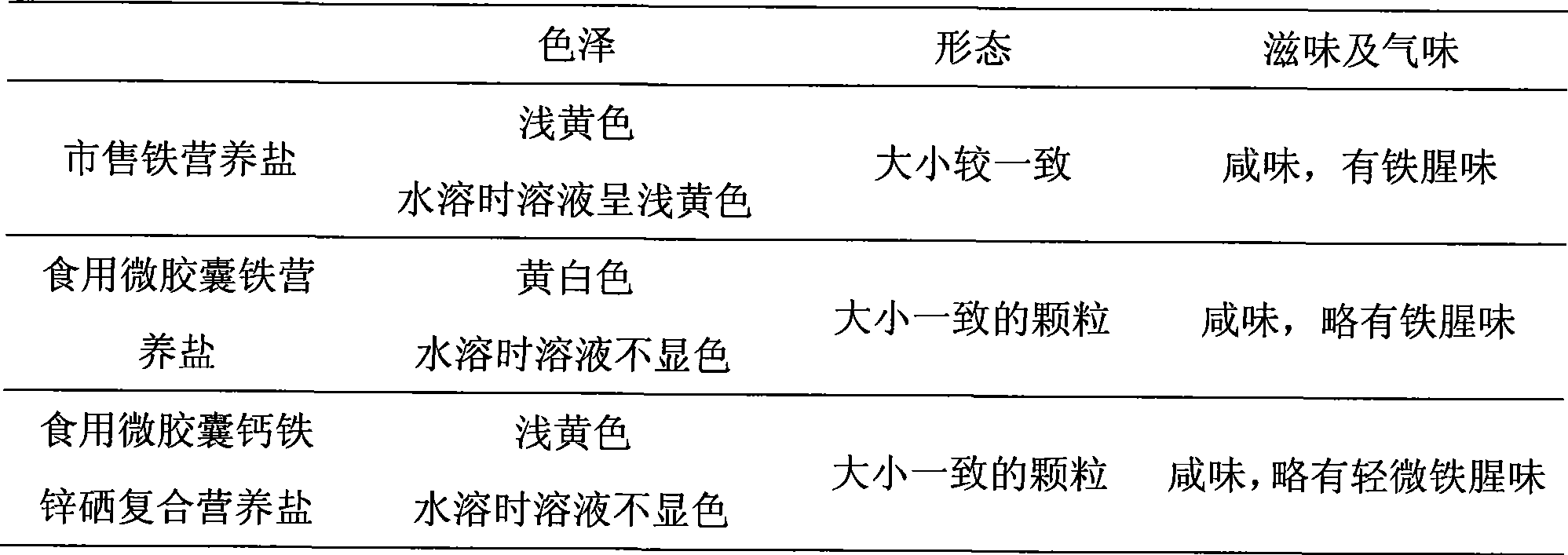

A technology of microcapsules and nutrient salts, which is applied in the field of food processing, can solve problems such as difficulty in mixing evenly, uneven color of nutrient salts, heavy iron smell, etc., and achieve the effect of improving nutritional value, consistent light yellow color, and light iron smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

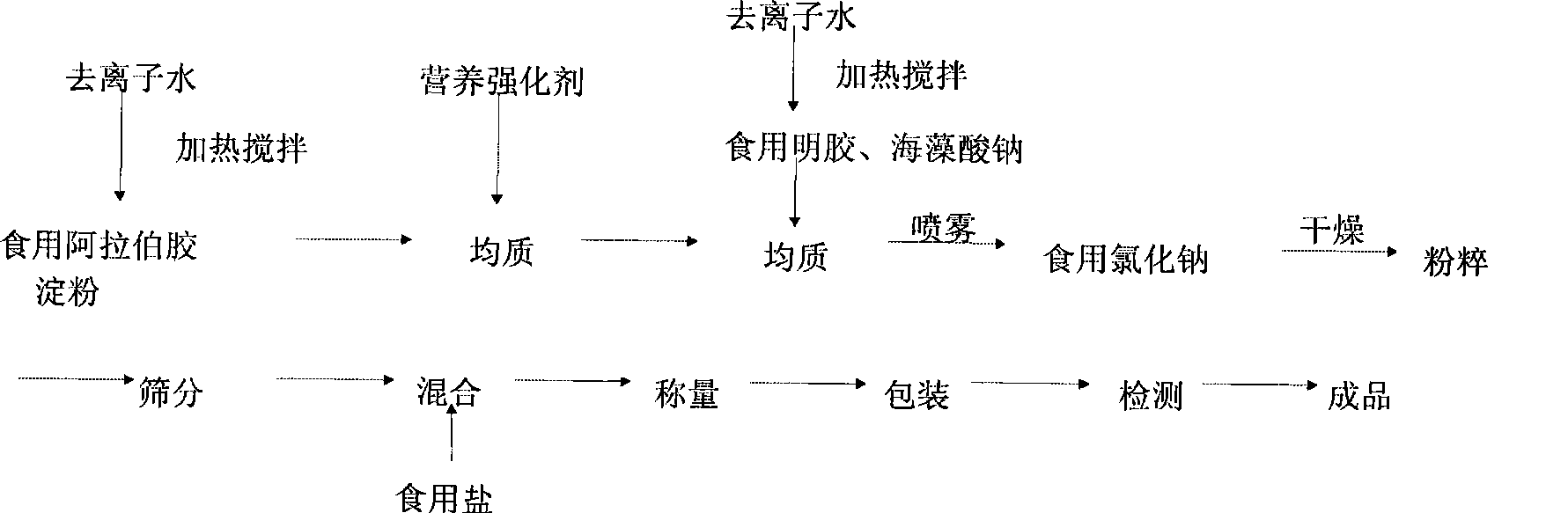

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 3000ml of deionized water into a container containing 10g of edible gum arabic and 20g of starch, heat up to 90°C, and after stirring thoroughly, add 30g of edible calcium lactate, stir for 5 minutes and put it into a homogenizer for homogenization Homogenization, the homogenization pressure is 40MPa, and the time is 40 minutes; in the material after the first homogenization, continue to add 1000ml of a solution containing 8% sodium alginate and 18% edible gelatin for the second homogenization, which is uniform The mass pressure is 40MPa, the time is 30 minutes, and it is ready for use;

[0032] (2) Add 800g of sodium chloride into a mixer with heating, heat while stirring, and raise the temperature to 90°C, then spray 5000ml of the second homogenized glue on the surface of sodium chloride evenly with a pressure spray device , while spraying, while stirring, the stirring time is 30 minutes, after spraying, keep warm for 25 minutes, the temperature is 90 ° C, and...

Embodiment 2

[0036] (1) Add 2000ml of deionized water to a container containing 5g of edible gum arabic and 35g of starch, heat up to 60°C, and after stirring thoroughly, add 40g of ferric sodium EDTA, stir for 5 minutes, and put it into a homogenizer for homogenization Homogenization, the homogenization pressure is 50MPa, and the time is 15 minutes; in the material after the first homogenization, continue to add 2000ml of a solution containing 5% sodium alginate and 20% edible gelatin for the second homogenization, the homogenization The pressure is 50MPa, the time is 30 minutes, and it is ready for use;

[0037] (2) Add 1000g of sodium chloride into a mixer with heating, heat while stirring, and raise the temperature to 70°C, then spray 6000ml of the second homogenized glue on the surface of sodium chloride evenly with a pressure spray device , while spraying, while stirring, the stirring time is 25 minutes, after spraying, keep warm for 30 minutes, the temperature is 80 ℃, make it dry; ...

Embodiment 3

[0041] (1) Add 500ml of deionized water into a container containing 15g of edible gum arabic and 5g of starch, heat up to 90°C, stir well, add 20g of sodium selenite, stir for 5 minutes and put it into a homogenizer Homogenization, the homogenization pressure is 30MPa, and the time is 30 minutes; in the material after the first homogenization, continue to add 2000ml of a solution containing 10% sodium alginate and 10% edible gelatin for the second homogenization, the homogenization The mass pressure is 30MPa, the time is 40 minutes, and it is ready for use;

[0042] (2) Add 400g of sodium chloride to a mixer with heating, heat while stirring, and raise the temperature to 90°C, then spray 3000ml of the second homogenized glue on the surface of sodium chloride evenly with a pressure spray device , while spraying, while stirring, the stirring time is 30 minutes, after spraying, keep warm for 25 minutes, the temperature is 90 ° C, and make it dry;

[0043] (3) Grinding the dry ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com