Polyarylether material containing azo group and fluorophor, as well as preparation and use thereof

A technology of fluorescent group and polyarylene ether, which is applied in the field of polymer material preparation, can solve the problems of complexity and limit large-scale use, and achieve the effect of wide application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

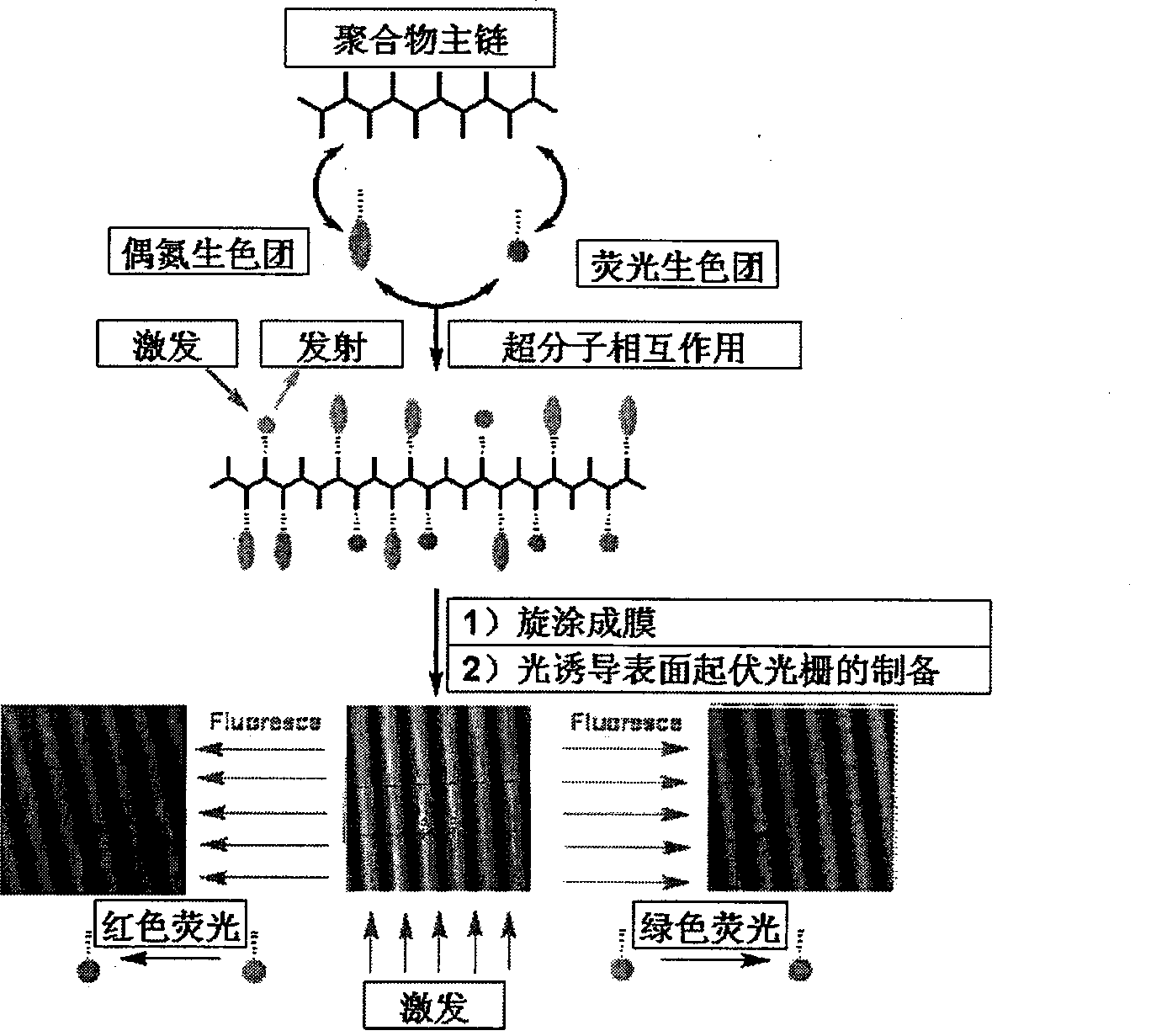

[0036] to combine figure 1 The process of preparing the fluorescent pattern in the present invention is described. figure 1 A schematic diagram of preparation of fluorescent patterns by the holographic method using polyarylether containing azo groups and fluorescent groups in the host and guest of the present invention is given. Azo groups, fluorescent groups, and polymers containing carboxyl groups or sulfonic acid groups in the side chains are prepared in a certain proportion into a solution, and then the polymer film is prepared by spin coating. The polymer film forms a surface relief grating under interference laser irradiation , under the irradiation of ultraviolet light, a fluorescent pattern with a grating structure can be obtained through a fluorescence microscope or a confocal fluorescence microscope. Moreover, patterns of different fluorescent colors can be realized by changing the type of fluorescent molecules.

Embodiment 2

[0038] Polyarylether, 4,4-dihydroxy azophenyl diphenyl sulfone, and rhodamine B containing carboxyl groups in the side chain are formulated into a solution with a mass concentration of cyclohexanone of 10% in a mass ratio of 88:10:2, and then After filtering with a 0.45 micron styrene filter head, spin-coat on a glass substrate to form a film, dry at 100°C for 12 hours, then heat up to 120°C for 12 hours in vacuum and put it in a desiccator for later use.

[0039] The obtained polymer thin film is under the interference of 355nm polarized laser (intensity 60mw / cm 2 ) for 30 seconds to form a surface relief grating.

[0040] Excited with ultraviolet light, regular red fluorescent patterns can be observed by fluorescence microscope or confocal fluorescence microscope.

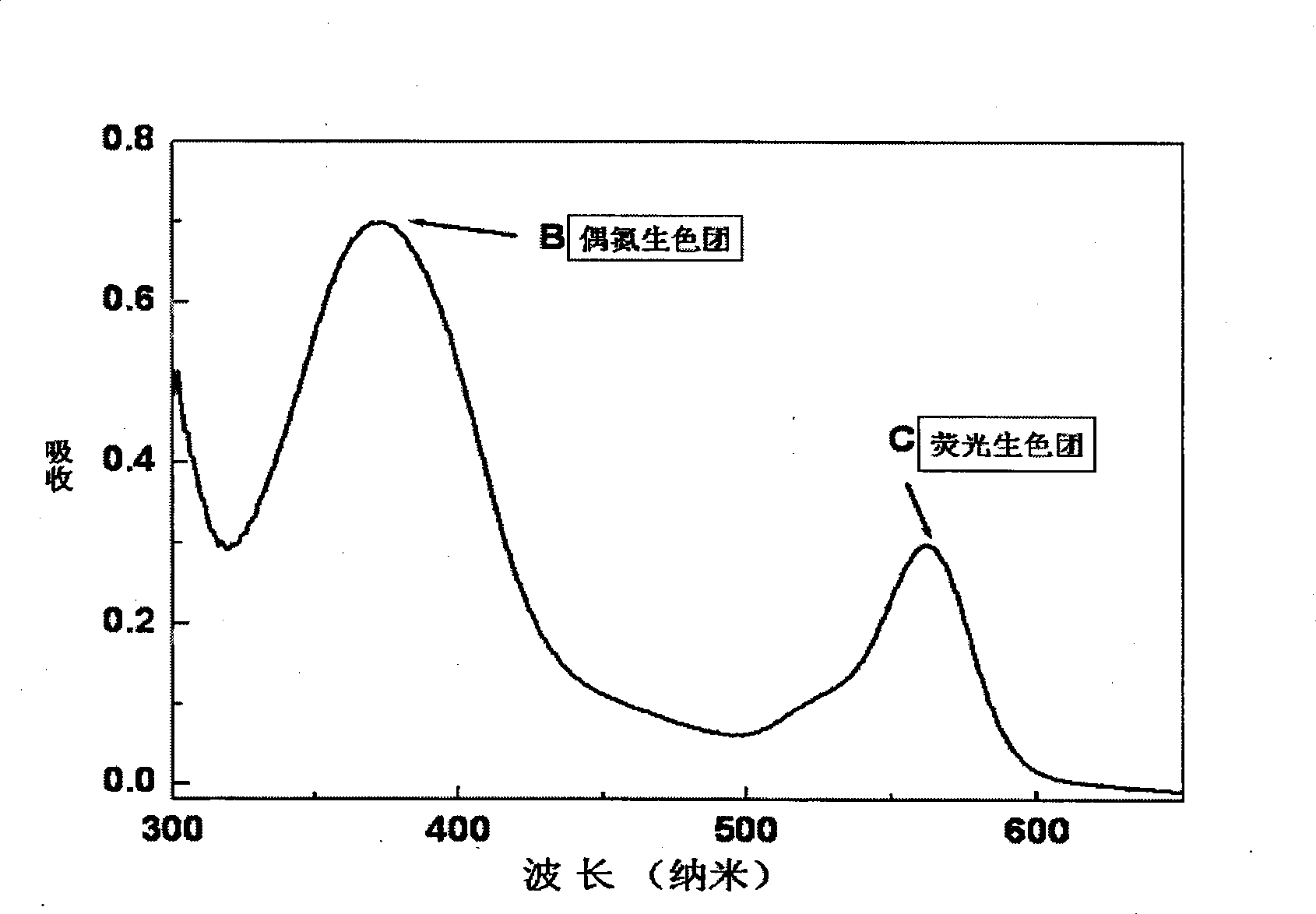

[0041] Such as figure 2 As shown, the figure shows the ultraviolet absorption spectrum of the host and guest containing azo groups and fluorescent groups (red) polyarylether. figure 2 The absorption peaks mark...

Embodiment 3

[0050] The process is the same as in Example 2, except that the fluorescent group rhodamine B is changed to aluminum octahydroxyquinoline.

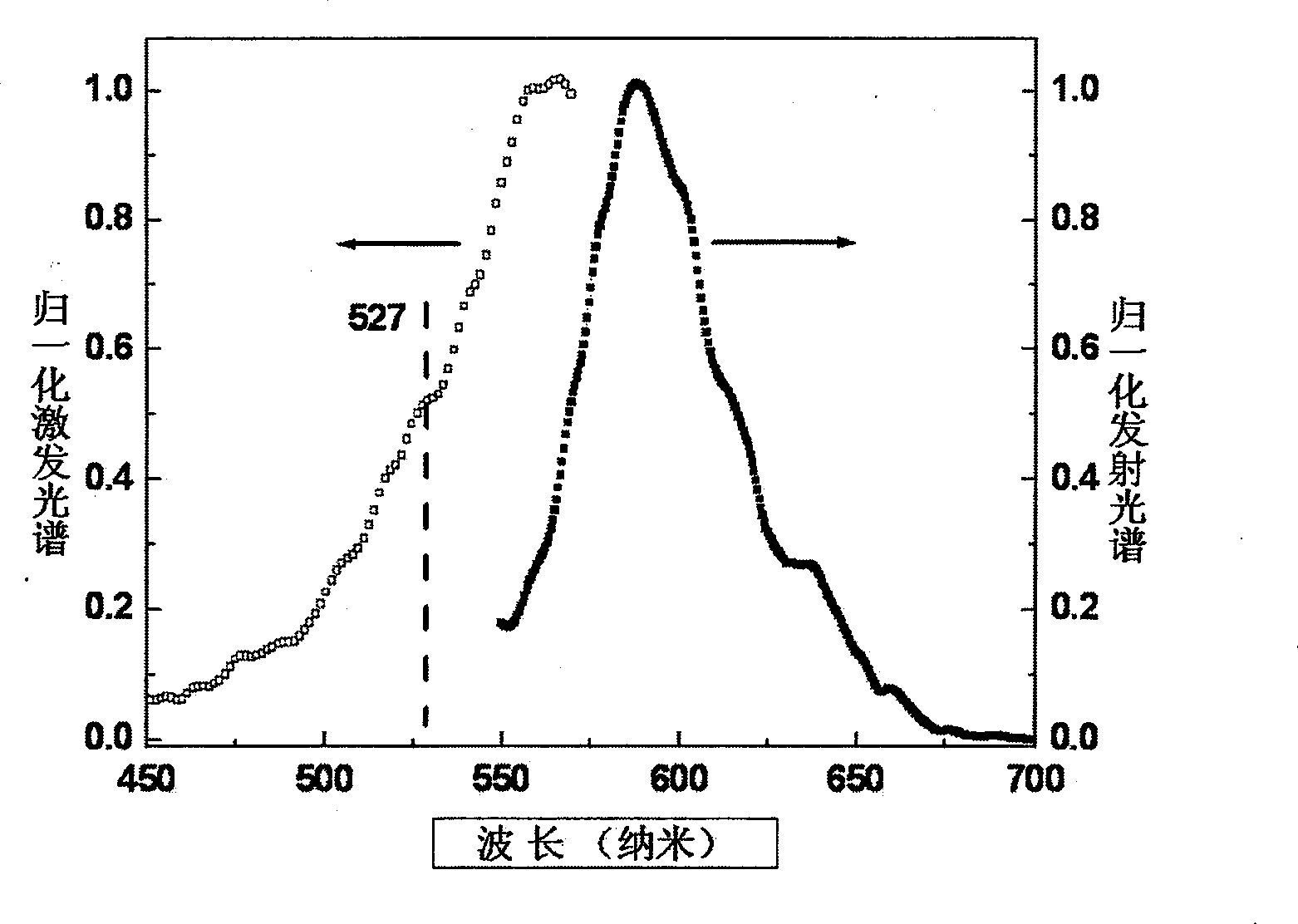

[0051] Such as Figure 8 as shown, Figure 8 The fluorescence spectrum of the host-guest type polyarylether film containing azo groups and fluorescent groups (green) is given. It can be seen that under the excitation of ultraviolet light, the obtained polymer film emits green fluorescence with a peak at about 520 nm.

[0052] see Figure 9 . Figure 9 The optical microscope pictures of host-guest type polyarylethers containing azo groups and fluorescent groups (green) are given. It can be seen that the complete periodic structure of the grating has a period of about 1.4 microns.

[0053] see Figure 10 . Figure 10 The fluorescence micrographs of the host and guest containing azo groups and fluorescent groups (green) polyarylether under ultraviolet light excitation are given. A complete fluorescent periodic structure pattern can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com