Solid phase preparation and use of organic modified calcium based montmorillonite

A technology of solid-phase preparation and organic modifier, applied in the field of organic modification of calcium-based montmorillonite, can solve the problems of unfavorable popularization, large energy consumption, complicated process and the like, achieves good industrial application value and low production cost , the effect of a wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Weigh 100g of calcium-based montmorillonite, 1g of dodecyltrimethylammonium chloride (DTAC) and 5g of coupling agent vinyltriethoxysilane and mix them together, and react with solid phase stirring at 100°C for 240min; The reaction product is discharged to obtain organic montmorillonite, which is denoted as DTAC-151.

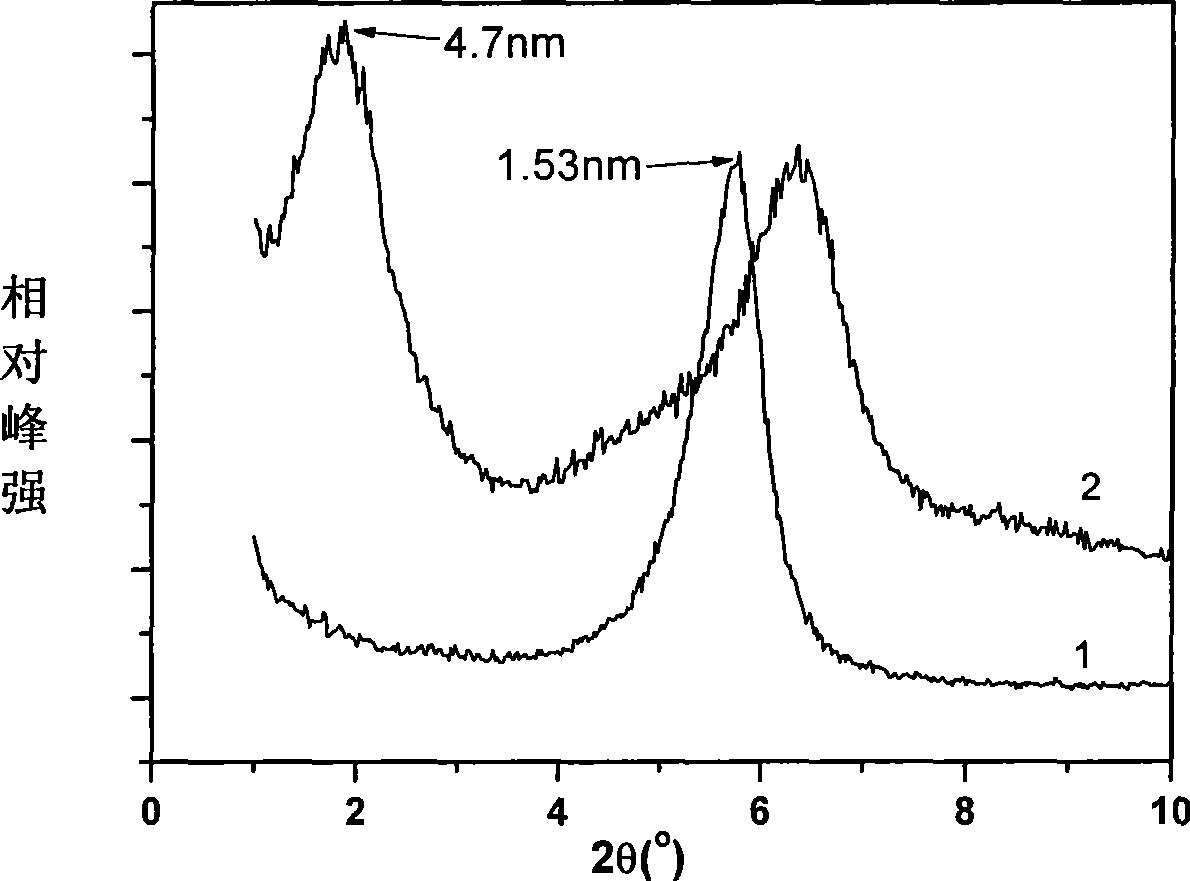

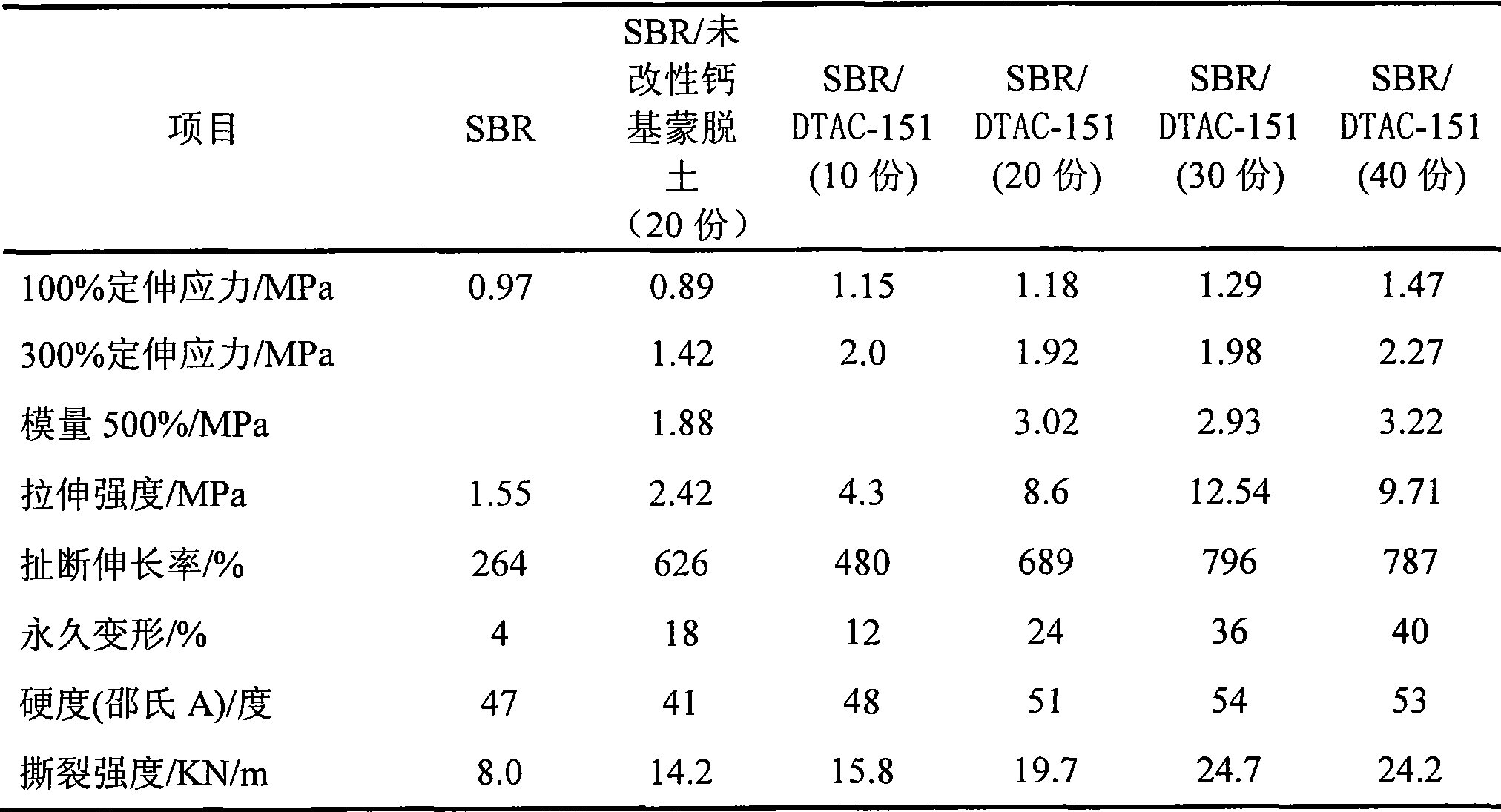

[0030] Add various compounding agents and vulcanizing agents and the above-mentioned organic montmorillonite according to the following formula. The formula is: 100 parts of styrene-butadiene rubber (SBR), 2 parts of stearic acid; 5 parts of zinc oxide; 1.5 parts of accelerator CZ; Agent DM 0.5 parts; sulfur 2 parts; montmorillonite variable. According to this formula, the SBR / DTAC-151 composite material was prepared by using different amounts of DTAC-151 and styrene-butadiene rubber, and the properties of the vulcanizate were tested. After the mixed rubber was parked overnight, it was vulcanized, and the test specimens were prepared according to the rele...

Embodiment 2

[0035] Take by weighing 100g calcium-based montmorillonite, 10g dodecyltrimethylammonium chloride (DTAC) and 3g coupling agent bis[3-(triethoxysilyl) propyl group] tetrasulfide and mix together, in Stir the reaction in solid phase at 100°C for 120 minutes; discharge the above reaction product to obtain organic montmorillonite, which is designated as DTAC-si69.

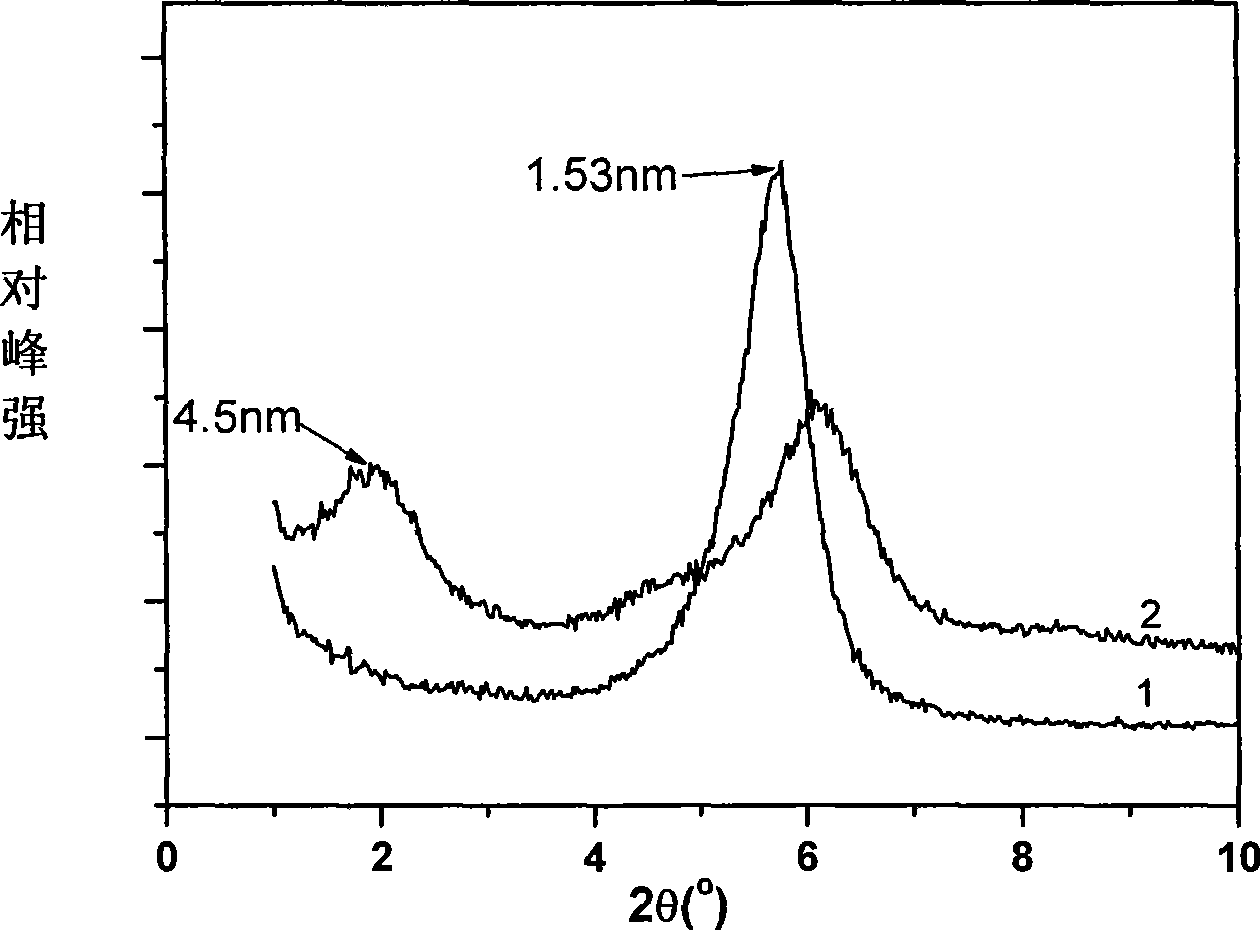

[0036] According to the formulation of Example 1, different amounts of DTAC-si69 and styrene-butadiene rubber were used to prepare SBR / DTAC-si69 composite materials, and the properties of the vulcanized rubber were tested. From the mechanical properties of the styrene-butadiene rubber / organically modified montmorillonite composite in Table 2, it can be seen that the addition of DTAC-si69 makes the mechanical properties of the composite significantly better than that of styrene-butadiene rubber / unmodified montmorillonite and pure styrene-butadiene rubber . figure 2 It is the XRD spectrum of the styrene-butadiene rubbe...

Embodiment 3

[0038] Weigh 100g of calcium-based montmorillonite, 20g of tetraethylenepentamine, and 1g of coupling agent vinyltriethoxysilane, mix them together, and stir and react in solid phase at 80°C for 240min; discharge the above reaction product to obtain organic montmorillonite off the soil.

[0039] Get 6g of the organic montmorillonite prepared in Example 3, according to the basic formula of the rubber compound: 100 parts of natural rubber NR, 2 parts of stearic acid; 5 parts of zinc oxide; 1.5 parts of accelerator CZ; 0.5 part of accelerator DM; 1.5 parts; 6 parts of montmorillonite, the composite material was prepared, vulcanized after parking overnight, the vulcanization condition was 143°C × normal vulcanization time (t 90 ). The performance of the vulcanizate of the composite material prepared in Example 3 is shown in Table 3. The mechanical properties of natural rubber / organic montmorillonite. It can be seen from Table 3 that the addition of organic montmorillonite has sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com