Complex fiber with high conductivity, high elasticity and stress sensing property and preparation thereof

A stress-sensing, high-conductivity technology, applied in fiber chemical characteristics, rayon manufacturing, single-component polyolefin rayon, etc. Falling off and other problems, to achieve the effect of good elasticity, low cost and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

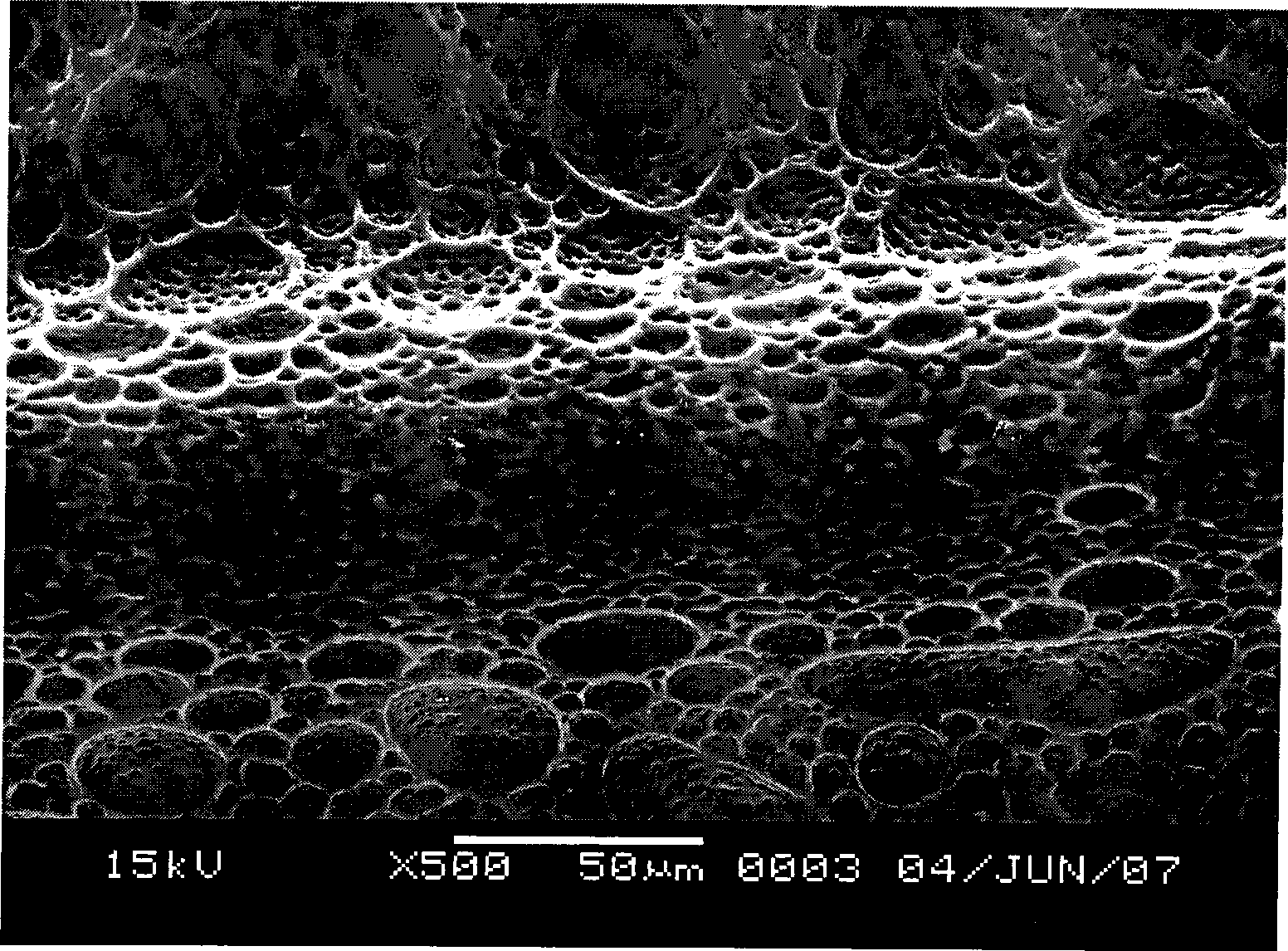

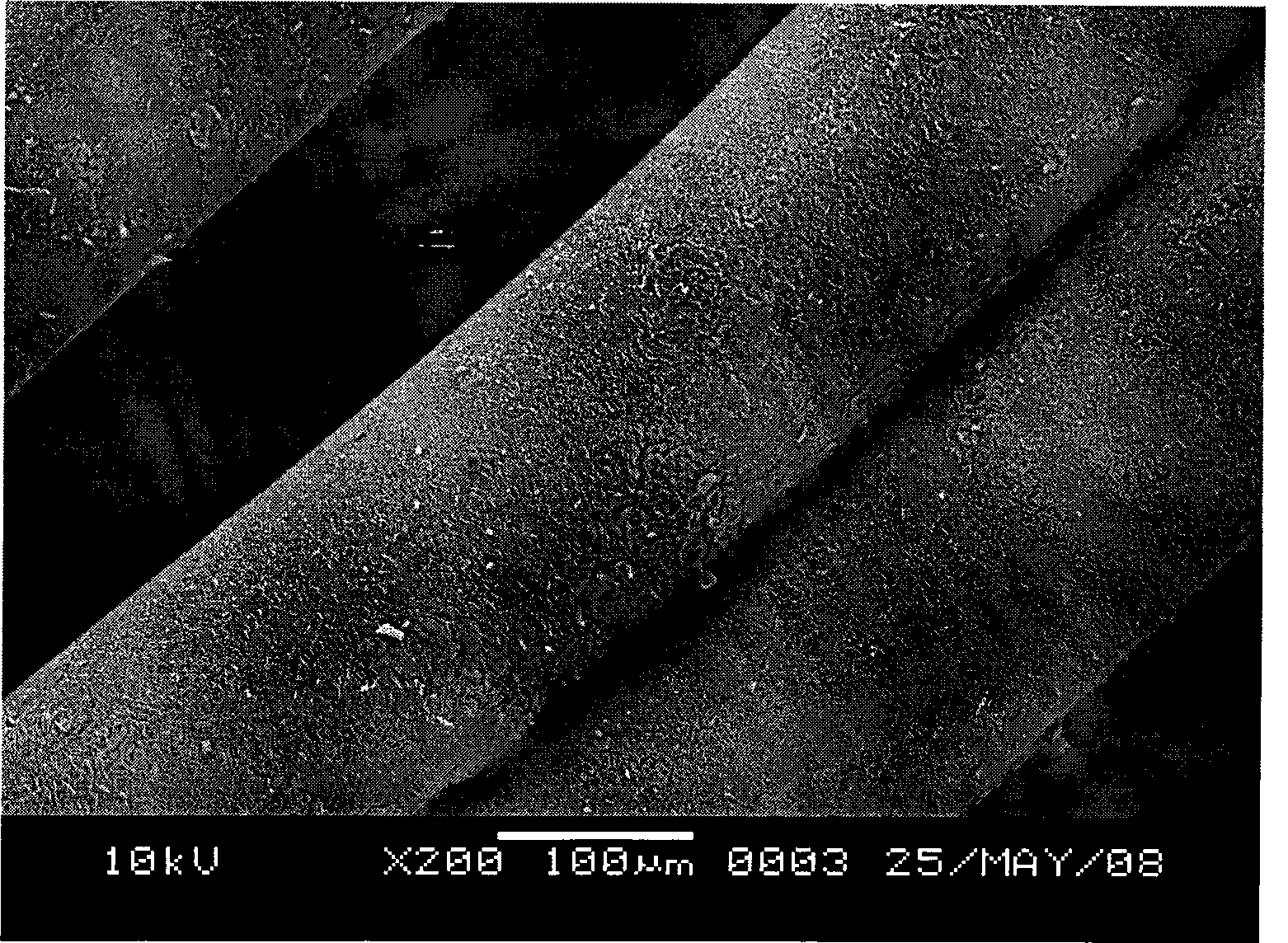

[0026] Add 100mg of multi-walled carbon nanotubes to 100ml of tetrahydrofuran, keep the temperature of the conductive medium bath at 0°C, and disperse with 100W ultrasonic assist, and pass the highly elastic polyolefin fibers through the carbon nanotube / tetrahydrofuran dispersion to control the dispersion of the fibers in the solvent. The soaking time is 5s, the composite fiber is obtained after the solvent volatilizes, the mass content of carbon nanotubes in it is 1%, and the resistivity of the composite fiber is 10 -2 Ω -1 cm -1 , The elongation at break is 500%.

Embodiment 2

[0028] Add 100mg single-walled carbon nanotubes to 100ml dimethylacetamide, keep the temperature of the conductive medium bath at 100°C, disperse with 50W ultrasonic assistance, and disperse the highly elastic polyamide fibers through the carbon nanotubes / dimethylacetamide liquid, control the soaking time of the fiber in the solvent to be 5s, obtain the composite fiber after the solvent volatilizes, the mass content of the carbon nanotube in it is 1%, and the resistivity of the composite fiber is 10 -2 Ω -1 cm -1 , The elongation at break is 500%.

Embodiment 3

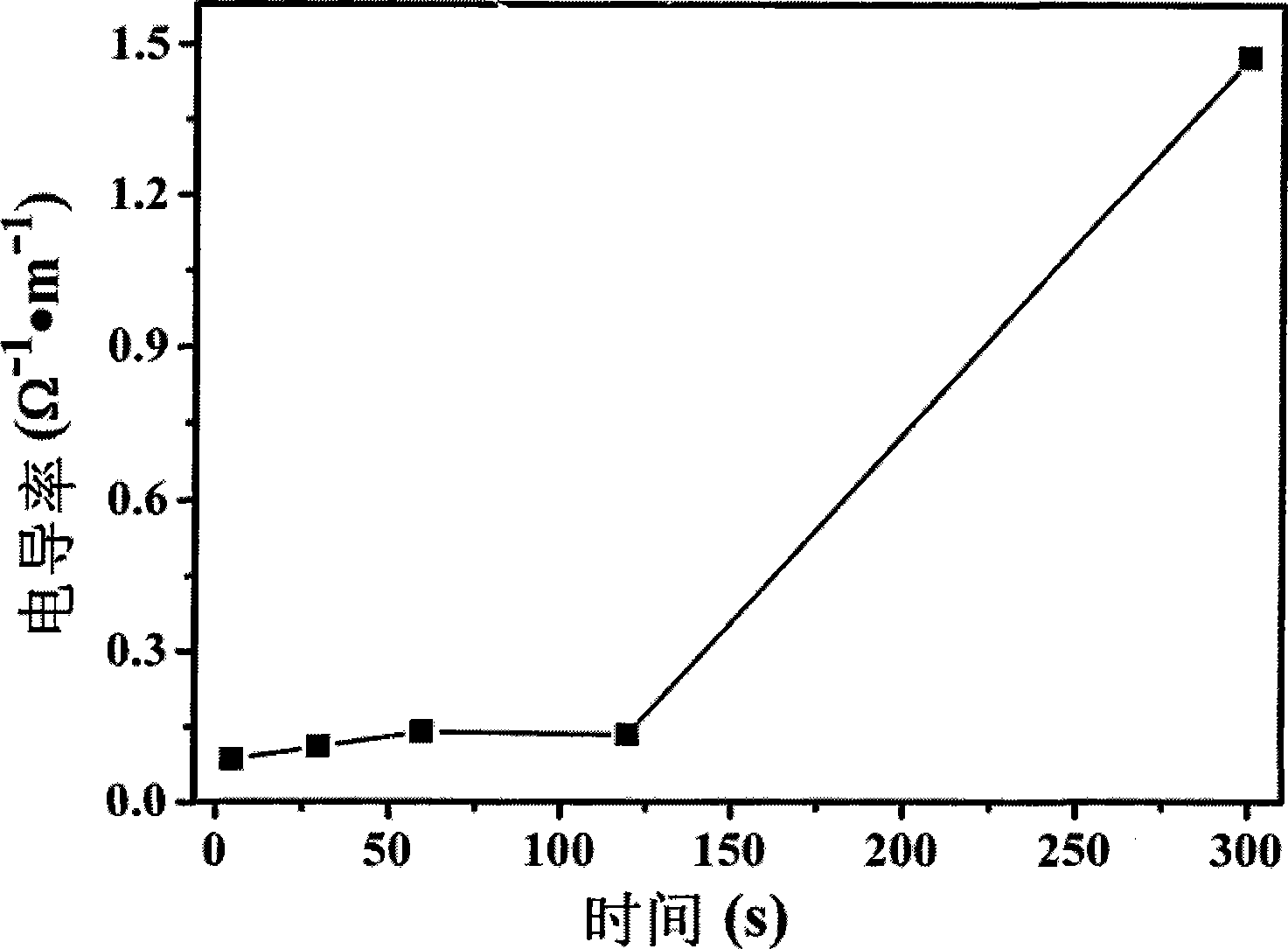

[0030]Add 100mg of multi-walled carbon nanotubes into 100ml of dichloroethane, keep the temperature of the conductive medium bath at 0°C, disperse with 50W ultrasonic assistance, and pass the polyurethane fiber through the carbon nanotube / dichloroethane dispersion to control the fiber in The soaking time in the solvent is 600s, and the composite fiber is obtained after the solvent volatilizes, the mass content of carbon nanotubes in it is 20%, and the resistivity of the composite fiber is 10 2 Ω -1 cm -1 , The elongation at break is 1500%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com