Zero point calibration method and its use in optical micro-scanning micro-thermal imaging system

A technology of micro-scanning and optical flat panel, which is applied in the field of scanning zero, can solve the problems that the spatial resolution of the system cannot be improved, the design of the optical flat-panel micro-scanning system falls short, and the quality is poor, so as to improve efficiency and reliability, light weight, The effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

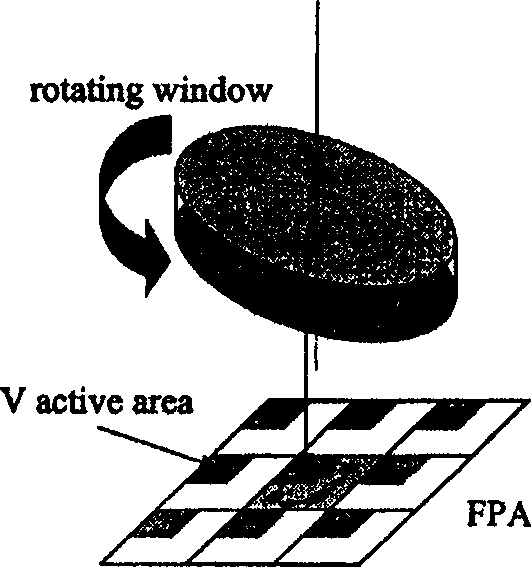

[0091] 1. Micro-scanning zero-point calibration of the actual optical micro-scanning micro-thermal imaging system

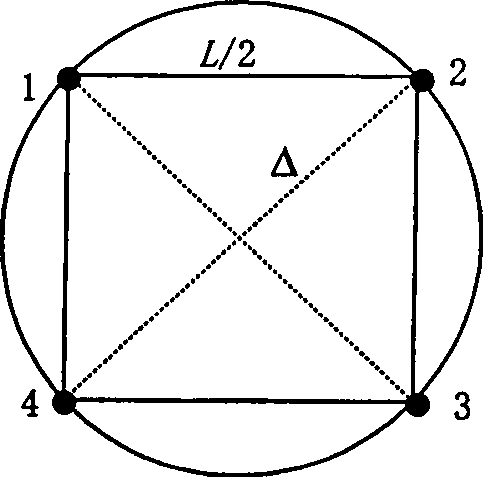

[0092] The zero-point calibration of the actual micro-thermography system is carried out by using the above-mentioned micro-scanning zero-point calibration method. Figure 9 The micro-displacement positions of four low-resolution images collected in the standard 2×2 micro-scan mode before and after micro-scanning zero point calibration are given, and the coordinate unit in the figure is 1 unit pixel. It can be seen that after micro-scanning zero-point calibration, the low-resolution image acquisition position is significantly closer to the upright regular quadrilateral than before calibration, which shows the effectiveness of the micro-scanning system zero-point calibration method.

[0093] Of course, due to the inevitable error factors such as mechanical vibration and environment in actual processing, assembly and system work, the micro-displacement positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com