Fast extraction and measurement method for plastid pigment in tobacco and tobacco products

A tobacco product and measurement method technology, applied in the field of tobacco chemical determination, can solve the problems of poor stability of carotenoid pigments, long extraction time, complicated pretreatment, etc., achieve shortened pretreatment time, high accuracy of measurement results, and easy operation Simple and easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

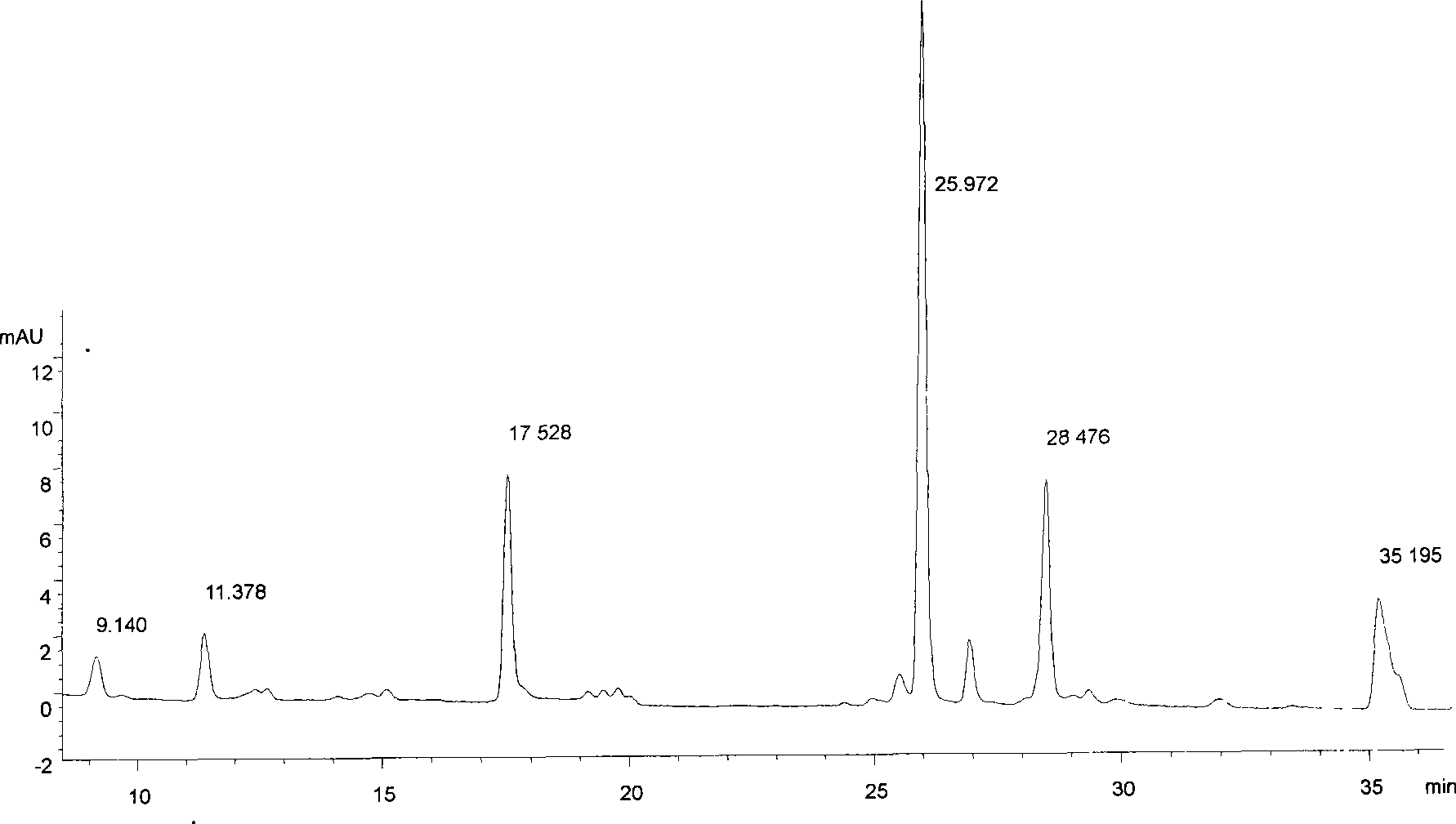

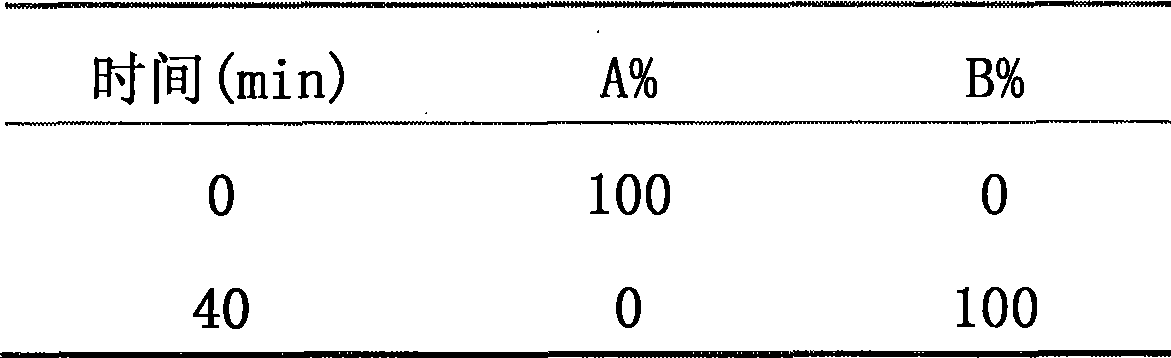

[0017] Take 500g of cured tobacco leaf sample according to the sample sampling standard, dry it at 40°C for 4h, crush it, pass it through a 40 mesh sieve, and the sample preparation is completed; accurately weigh 5.0000g of the prepared sample (accurate to 0.0001g), and pour it into 100ml Erlenmeyer flask, pour 40ml of 90% acetone (containing 0.1% dibutyl hydroxytoluene BHT) into the Erlenmeyer flask, ultrasonic extraction at room temperature for 20min, filter, and then use 10ml of 90% acetone (containing 0.1% dibutyl hydroxytoluene BHT) for the filter residue Hydroxyl toluene (BHT) was washed 2-3 times, the filtrate was combined, and the volume was adjusted to 100ml, and 2mL of the extract was taken, filtered with a 0.45μm microporous membrane, and the filtrate was analyzed by HPLC and quantified by the external standard method; wherein, the chromatographic column was SymmetryC18 Phase chromatographic column (3.9mm i.d. × 150mm, 4 μm) (Waters Company, USA); Mobile phase is: A,...

Embodiment 2

[0022] According to the sample sampling standard, take 500g of finished cigarette samples, dry them at 40°C for 4 hours, crush them, pass through a 40-mesh sieve, and the sample preparation is completed; accurately weigh 5.0000g of the prepared samples (accurate to 0.0001g), and pour them into a 100ml triangular bottle, pour 40ml of 90% acetone (containing 0.1% dibutylhydroxytoluene BHT) into the conical flask, ultrasonically extract at room temperature for 20min, filter, and then use 10ml of 90% acetone (containing 0.1% dibutyl hydroxytoluene BHT) to filter the residue Hydroxytoluene (BHT) was washed 2 to 3 times, the filtrate was combined, and the volume was adjusted to 100ml, and 2mL of the extract was taken, filtered with a 0.45 μm microporous membrane, and the filtrate was analyzed by HPLC and quantified by the external standard method; the chromatographic column was a SymmetryC18 reverse-phase chromatographic column (3.9mm i.d.×150mm, 4μm) (Waters, USA); mobile phase: A, ...

Embodiment 3

[0024] Take 3000g of fresh tobacco leaves from the field, freeze-dry them at -45°C, crush them, pass through a 40-mesh sieve, and the sample preparation is completed; accurately weigh 1.0000g of the prepared sample (accurate to 0.0001g), pour it into a 100ml conical flask, and use 40ml90 % acetone (containing 0.1% dibutyl hydroxytoluene BHT) was poured into a conical flask, ultrasonically extracted at room temperature for 20 min, filtered, and the filter residue was washed with 10 ml of 90% acetone (containing 0.1% dibutyl hydroxytoluene BHT) for 2 ~ 3 times, combine the filtrate, dilute to 100ml, take 2mL extract, filter with 0.45μm microporous membrane, carry out HPLC analysis on the filtrate, quantify by external standard method; chromatographic column is SymmetryC18 reversed-phase chromatographic column (3.9mm i.d.×150mm , 4 μm) (U.S. Waters Company); Mobile phase is: A, 80% acetonitrile: isopropanol=1:1, B, ultrapure water; Flow velocity is 0.5ml / min, gradient elution; Det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com