Polyester dispersant, process for production of the same, and pigment composition using the same

A technology of dispersants and vinyl polymers, applied in the field of polyester dispersants, which can solve the problems of low viscosity and reduced coating resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

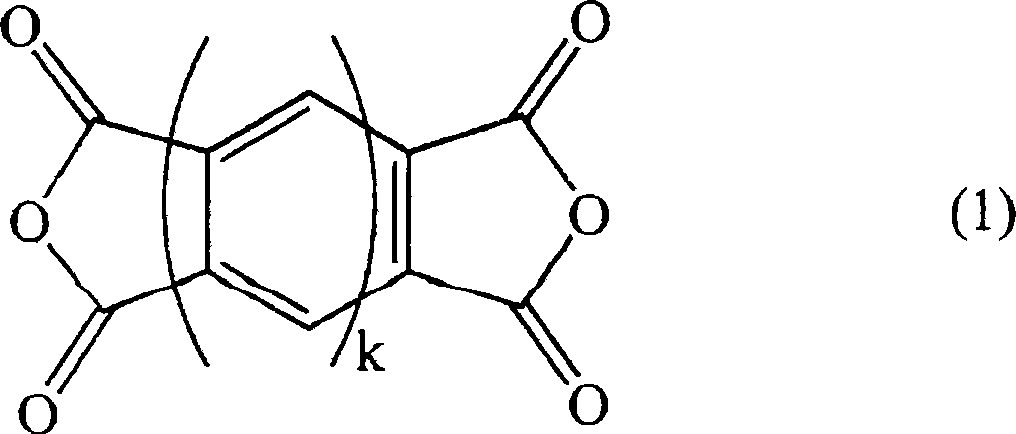

[0275] In a reaction vessel equipped with a gas introduction pipe, a thermometer, a condenser and a stirrer, 200 parts of n-butyl methacrylate were added, and the reaction vessel was purged with nitrogen. The inside of the reaction container was heated to 80°C, 12 parts of 3-mercapto-1,2-propanediol was added, and the reaction was carried out for 12 hours. 95% reaction was confirmed by solid content measurement. Next, add 12 parts of pyromellitic anhydride, 224 parts of cyclohexanone, and 0.40 parts of 1,8-diazabicyclo-[5.4.0]-7-undecene as a catalyst, and react at 120°C for 7 Hour. It was confirmed by measuring the acid value that 98% or more of the acid anhydride had been half-esterified, and the reaction was terminated to obtain a polyester dispersant with an acid value of 28 and a weight average molecular weight of 5800 (=dispersant 1, the same applies hereinafter).

Embodiment 2~6

[0277] Except having used the raw material and addition amount shown in Table 1, it synthesize|combined by the method similar to Example 1, and obtained the polyester dispersing agent.

Embodiment 7

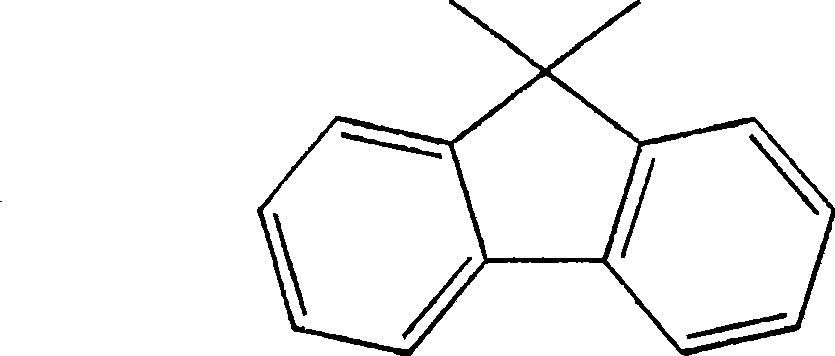

[0279] 100 parts of n-butyl methacrylate and 100 parts of benzyl methacrylate were added to a reaction vessel equipped with a gas inlet tube, a thermometer, a condenser and a stirrer, and the reaction vessel was purged with nitrogen. The inside of the reaction container was heated to 80°C, and a solution in which 0.1 part of 2,2'-azobisisobutyronitrile was dissolved in 12 parts of 3-mercapto-1,2-propanediol was added, and reacted for 10 hours. 95% reaction was confirmed by solid content measurement. 19 parts of pyromellitic anhydride, 231 parts of cyclohexanone, and 0.40 parts of 1,8-diazabicyclo-[5.4.0]-7-undecene as a catalyst were added and reacted at 120° C. for 7 hours. By measuring the acid value, it was confirmed that more than 98% of the acid anhydride had been half-esterified, and then the reaction was terminated to obtain a polyester dispersant with an acid value of 43 and a weight average molecular weight of 8500.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com