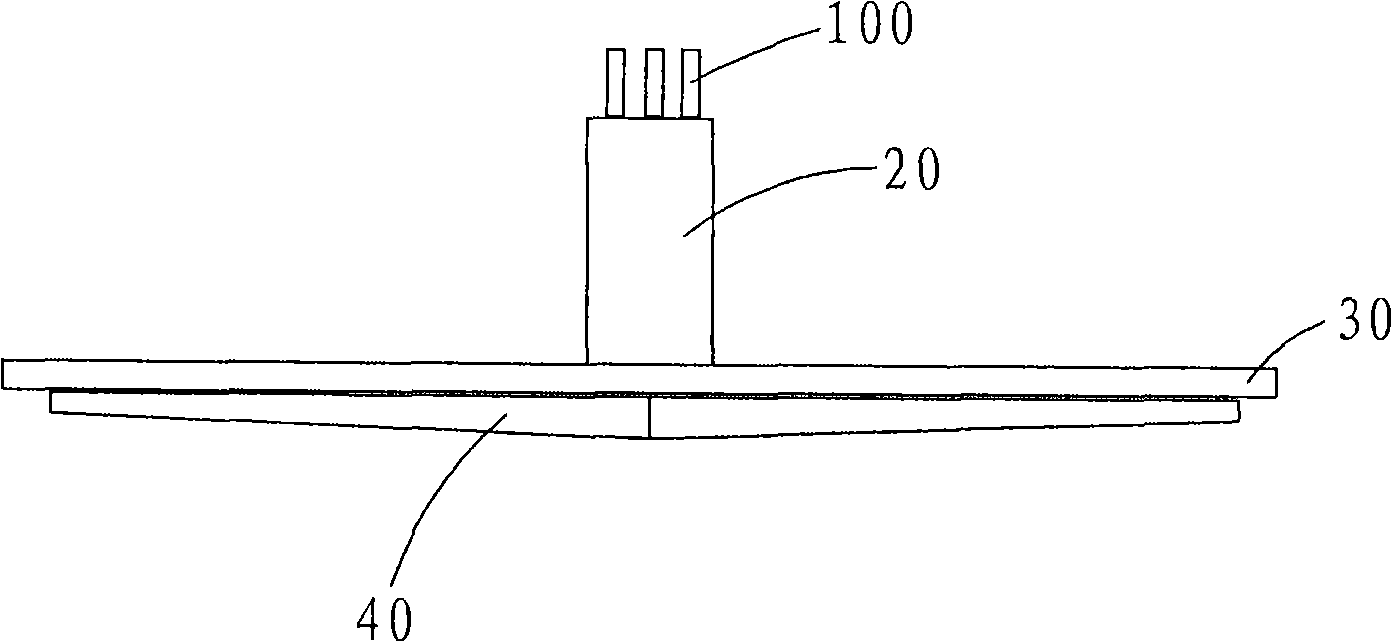

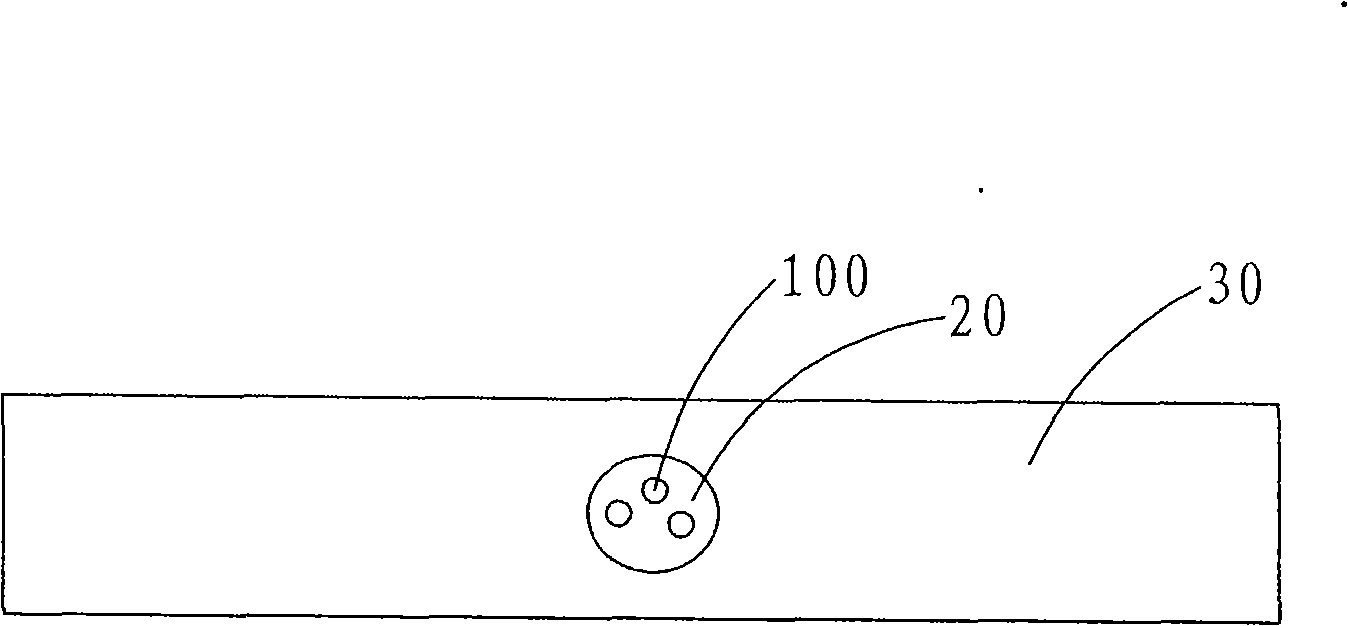

Nozzle system capable of continuously evening chemical vapour deposition of large area

A chemical vapor deposition, large-area technology, used in gaseous chemical plating, metal material coating processes, coatings, etc., which can solve nozzle blockage, film thickness, uneven optical and electrical properties of components, and change the composition of the reaction mixture gas. ingredients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific approach 1

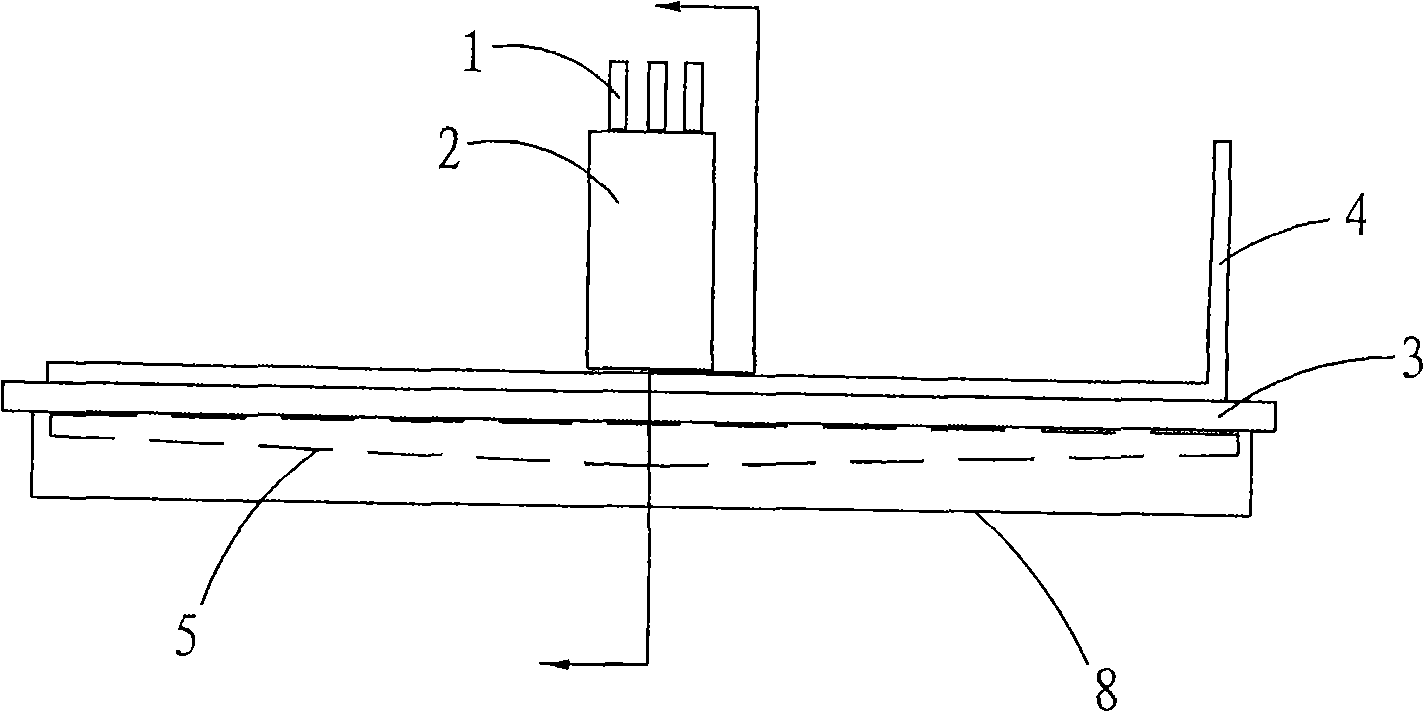

[0043] Concrete plan one: the V-shaped angle of the secondary reaction gas mixing chamber 8 is 20°, the volume ratio of the secondary reaction gas mixing chamber 8 and the volume of the nozzle 5 is 4:1, the secondary reaction gas mixing chamber The ratio of 8 to the volume of the primary reaction gas mixing chamber 2 is 1:1. Circulating water cooling system 4 The ratio of the cooling water pipe through which the cooling water circulates and the fixed panel 3 of the nozzle 5 to the area of the fixed panel 3 of the entire nozzle 5 is 1 / 8; the cooling is regulated by a continuously adjustable flow controller The water velocity is 1.2 meters per second and the flow rate is controlled at 60 liters per minute. It is actually measured that the mixing temperature of the reaction gas in the primary reaction gas mixing chamber 2 on the upper part of the fixed panel 3 of the nozzle 5 is between 87°C and 119°C, and the mixed reaction gas measured by three uniformly distributed thermocou...

specific approach 2

[0044] Concrete plan two: the V-shaped angle of the secondary reaction gas mixing chamber 8 is 15°, the ratio of the volume of the secondary reaction gas mixing chamber 8 to the volume of the nozzle 5 is 4:1, the secondary reaction gas mixing chamber The ratio of 8 to the volume of the primary reaction gas mixing chamber 2 on the upper part of the fixed panel 3 of the nozzle 5 is 1:1. Circulating water cooling system 4 The ratio of the cooling water pipe through which the cooling water circulates and the fixed panel 3 of the nozzle 5 to the area of the fixed panel 3 of the entire nozzle 5 is 1 / 11; the cooling water is adjusted by a continuously adjustable flow controller The flow rate is 1.5 meters per second and the flow rate is controlled at 50 liters per minute. It is actually measured that the mixing temperature of the reaction gas in the primary reaction gas mixing chamber 2 on the upper part of the fixed panel 3 of the nozzle 5 is between 94°C and 123°C, and the mixed ...

specific approach 3

[0045] Concrete scheme three: the angle of the V shape of the secondary reaction gas mixing chamber 8 is 20 °, the volume ratio of the volume of the secondary reaction gas mixing chamber 8 and the nozzle 5 is 4: 1, the secondary reaction gas mixing chamber The volume ratio of the body 8 and the primary reaction gas mixing chamber 2 on the upper part of the fixed panel 3 of the nozzle 5 is 1:1. Circulating water cooling system 4 The ratio of the cooling water pipe through which the cooling water circulates and the fixed panel 3 of the nozzle 5 to the area of the fixed panel 3 of the entire nozzle 5 is 1 / 11; the cooling is regulated by a continuously adjustable flow controller The water velocity is 1.5 meters per second and the flow rate is controlled at 60 liters per minute. It is actually measured that the mixing temperature of the reaction gas in the primary reaction gas mixing cavity 2 on the upper part of the fixed panel 3 of the nozzle 5 is between 97°C and 126°C, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com