System and method for monitoring semiconductor processing technique

A technology of processing technology and monitoring system, applied in semiconductor/solid-state device testing/measurement, semiconductor/solid-state device manufacturing, electrical components, etc. Ratio and other issues to achieve the effect of improving signal-to-noise ratio and resolution, improving accuracy and reliability, and realizing precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

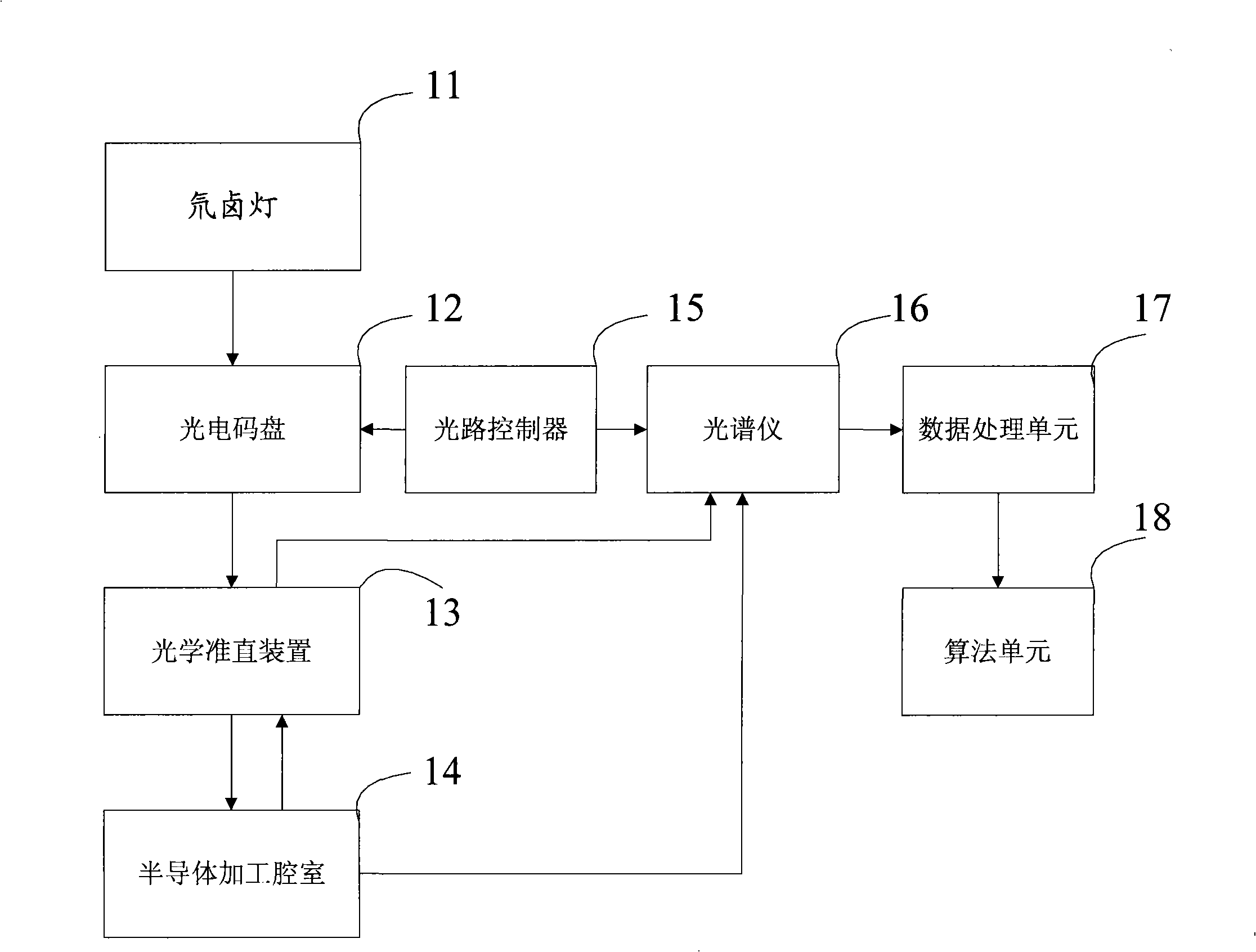

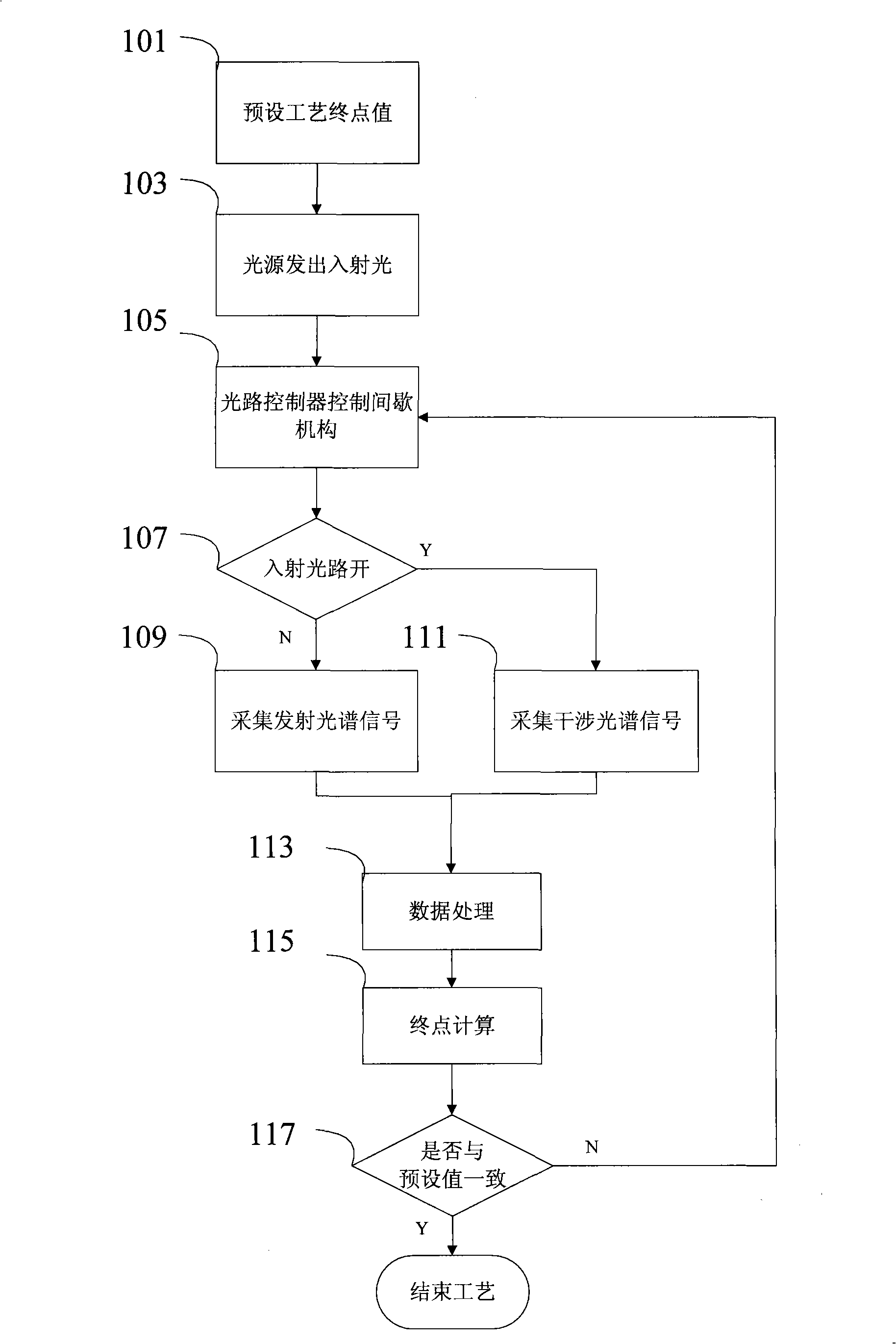

[0037] The present invention discloses a monitoring system and method for semiconductor processing technology, referring to figure 1 and figure 2 An embodiment of the present invention is described. figure 1 It is a schematic diagram of the monitoring system of the semiconductor processing technology described in this embodiment, figure 2 It is a schematic flowchart of the monitoring method of the semiconductor processing technology described in this embodiment.

[0038] Such as figure 1 As shown, the monitoring system of the semiconductor processing technology described in this embodiment includes: a high-power deuterium-halogen lamp 11, a photoelectric code disc 12, an optical collimation device 13, an optical path controller 15, a multi-channel CCD spectrometer 16, and a data processing unit 17 and arithmetic unit 18.

[0039]The deuterium halogen lamp 11 provides a broadband continuous light source, and its spectral range is 180-2000nm, which is used to emit continuo...

Embodiment 2

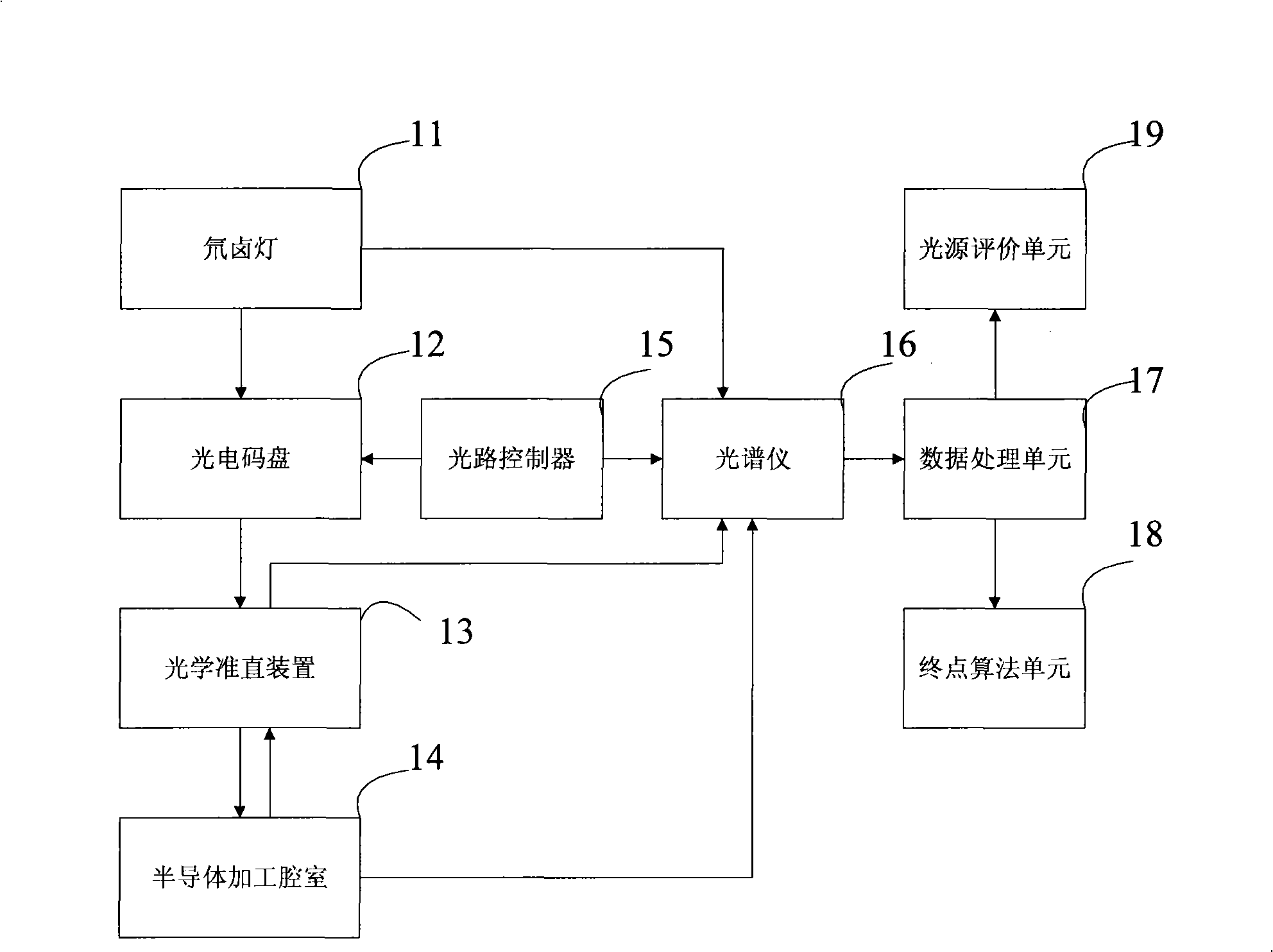

[0048] In the process of semiconductor processing process monitoring, the drift and disturbance of the intensity of the light source will reduce the resolution of the interference spectrum signal, which directly affects the accuracy and reliability of process monitoring. Therefore, the semiconductor processing process monitoring system and method described in this embodiment also A light source evaluation unit is provided to monitor the stability and lifetime of the continuous light source in real time. The following is attached image 3 and Figure 4 The present embodiment is explained.

[0049] Such as image 3 The monitoring system of the semiconductor processing technology described in the shown embodiment includes: a high-power deuterium-halogen lamp 11, a photoelectric code disc 12, an optical collimation device 13, an optical path controller 15, a multi-channel CCD spectrometer 16, and a data processing unit 17. An algorithm unit 18 and a light source evaluation unit...

Embodiment 3

[0054] Before the OES and IEP endpoint algorithms, it is necessary to perform data processing on the signals collected by the multi-channel CCD spectrometer 16 . The emission spectrum data records the plasma state of the reactive gas and generated gas participating in the etching process during the processing process, and the information that the strength of the same spectrum changes with the amount of reactants or products during the etching process; interference The spectral data records the periodically changing reflected light intensity information due to the change of the wafer film layer in the processing chamber during the process; and the light source intensity data records the change information of the light source intensity during the process.

[0055] This embodiment describes the processing method of the OES, IEP and light source intensity data of the semiconductor processing process monitoring system with reference to the accompanying drawings.

[0056] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com