Tungsten copper connection method

A connection method, tungsten-copper technology, applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems of limited application and complicated preparation process, and achieve the effect of simple process operation, good connection effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

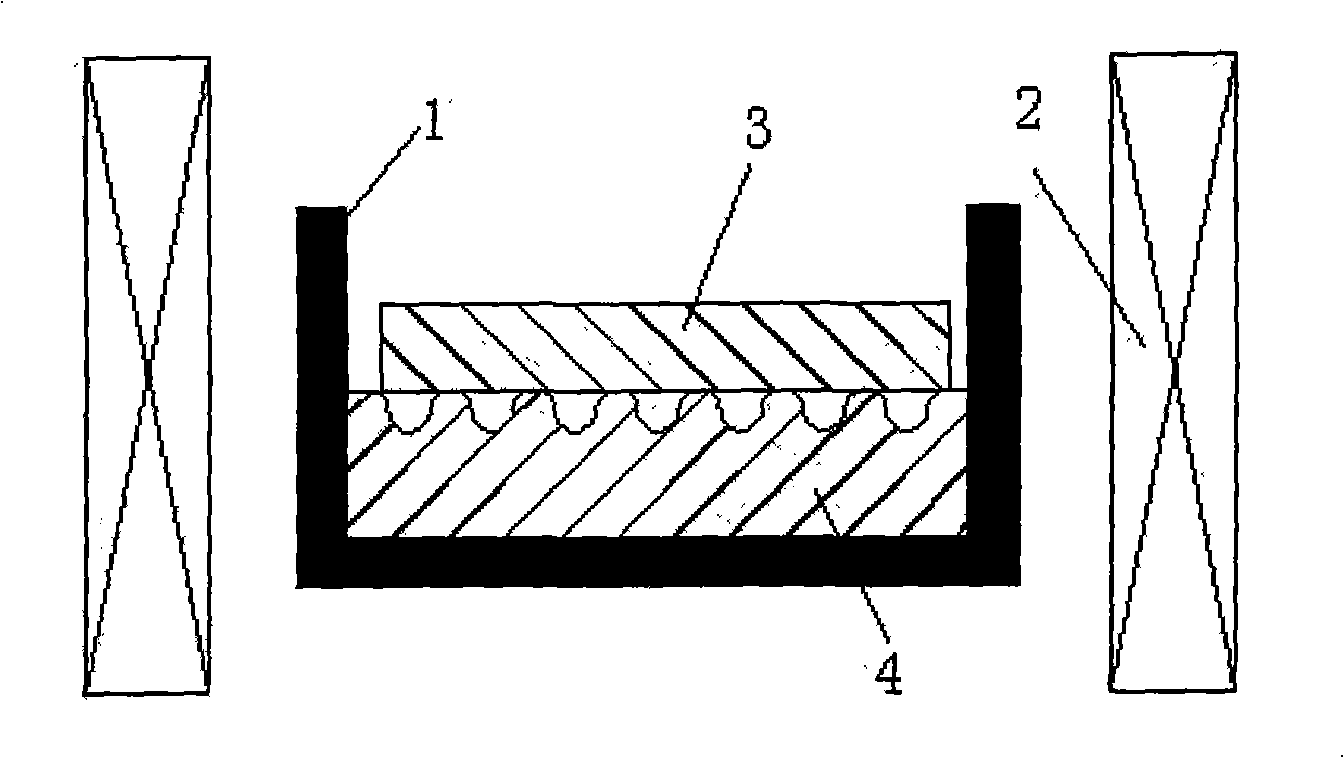

[0023] Industrial pure tungsten is connected with CuCrZr alloy, and the sample size is 30mm×30mm×5mm and 30mm×30mm×30mm respectively. The main points of the connection process are as follows:

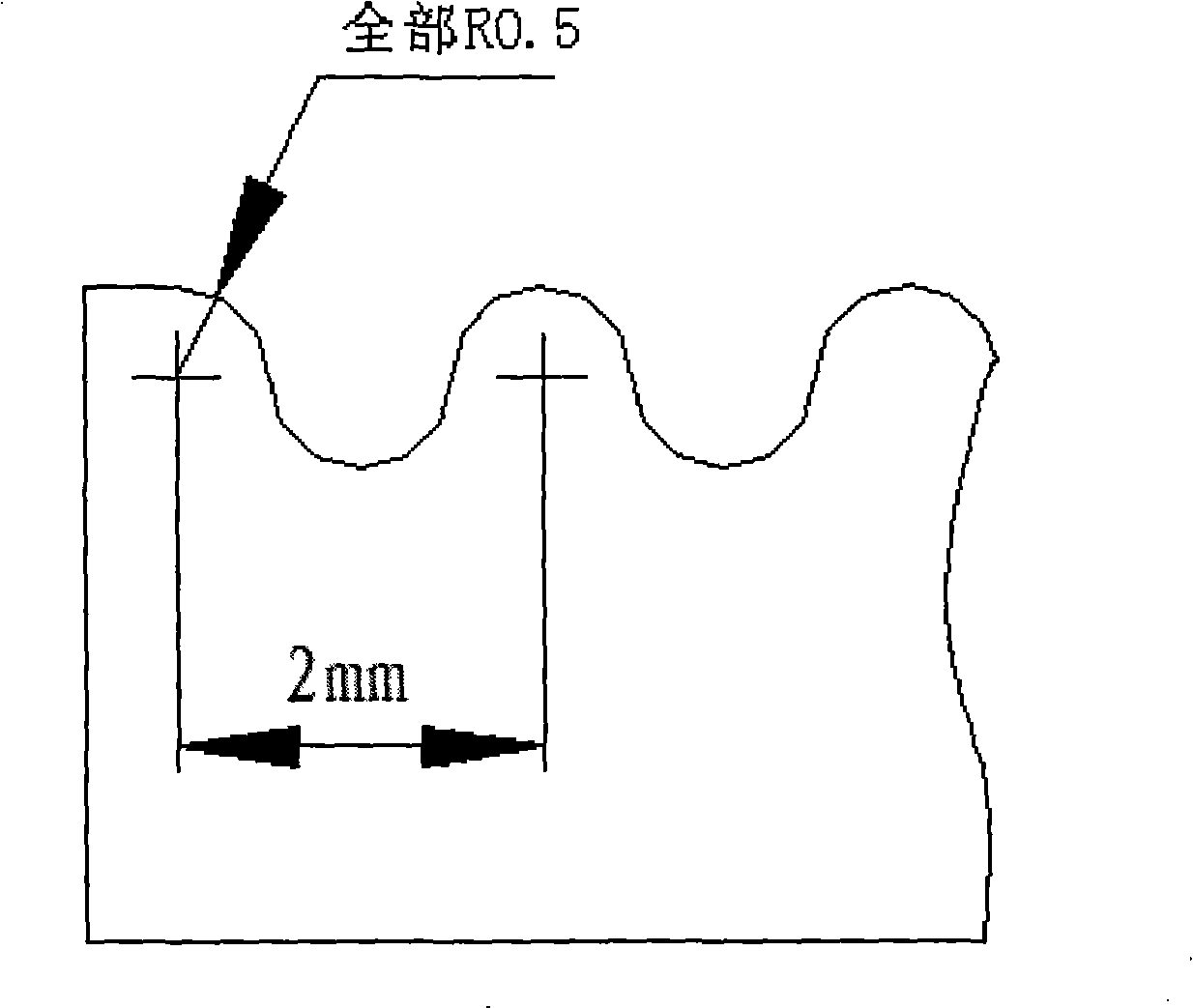

[0024] 1. Tungsten metal surface processing: use wire cutting to process wave grooves on the tungsten surface. The shape and size of the grooves are as attached. figure 2 Shown:

[0025] 2. Surface treatment of tungsten metal and copper metal: the tungsten wave surface is polished with metallographic sandpaper, and then cleaned with alcohol and acetone respectively; the pure copper to be cladding is polished with metallographic sandpaper, and then cleaned with alcohol and acetone respectively;

[0026] 3. Cladding: Put the pure copper to be cladding on the tungsten wave surface, put it in a graphite mold, and place it in a vacuum diffusion furnace. The heating rate is 180℃ / h, the holding temperature is 1160°C, and the holding time is 30 minutes. Cool slowly. After cladding, the thickness of...

Embodiment 2

[0030] In the cladding step, the heating rate is 150°C / h, the holding temperature is 1150°C, and the holding time is 40 minutes.

[0031] In the vacuum diffusion welding step, the heating temperature is 900°C, the holding time is 45 minutes, and the connection pressure is 8MPa.

[0032] The rest of the procedures and process parameters are the same as in Example 1.

Embodiment 3

[0034] Use industrial pure tungsten to connect with CuZn alloy (brass).

[0035] In the cladding step, the heating rate is 200°C / h, the holding temperature is 1200°C, and the holding time is 10 minutes.

[0036] In the vacuum diffusion welding step, the heating temperature is 850°C, the holding time is 90 minutes, and the connection pressure is 12 MPa.

[0037] The remaining procedures and process parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com