Phosphine copolyamide / nano montmorillonite flame-retardant composite material and preparation thereof

A technology of flame-retardant composite materials and nano-montmorillonite, which is applied in the field of phosphine-containing copolyamide/nano-montmorillonite flame-retardant composite materials and its preparation, can solve the problems of low mechanical properties of polyamide, large amount of inorganic flame retardants, and In order to avoid problems such as poor combustion effect, it can achieve the effect of excellent performance, high flame retardant efficiency, and increased safety in use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the phosphine-containing copolyamide / nano-montmorillonite flame-retardant composite material in the present embodiment, its parts by weight are 10 parts of organic montmorillonite dispersed in nanoparticles by 15 parts by weight of phosphine-containing prepolymer and parts by weight of In the phosphine-containing copolyamide synthesized by 75 parts of nylon 66 salt.

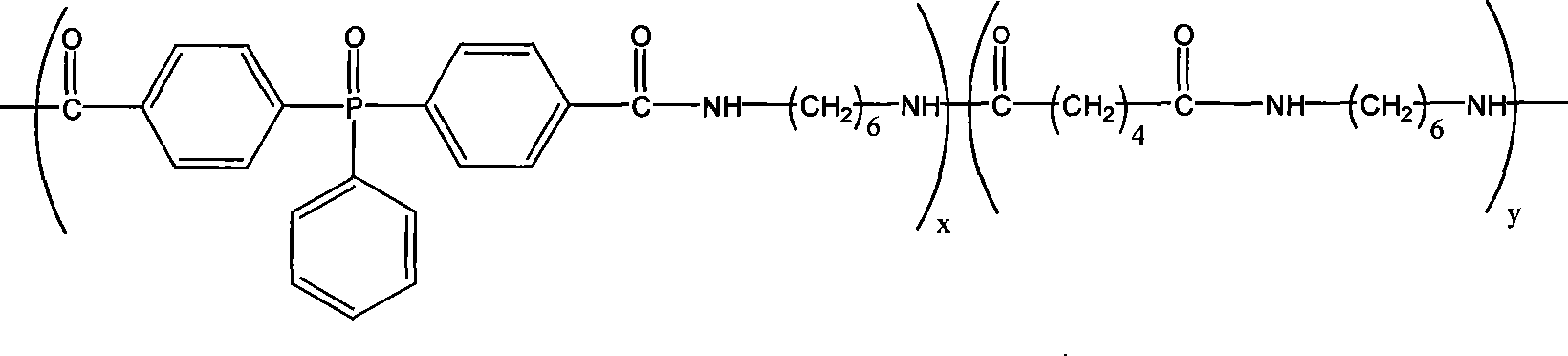

[0023] The polymeric molecular structure of the above-mentioned phosphine-containing copolyamide is

[0024]

[0025] x=1-100; y=1-100.

[0026] The intrinsic viscosity of the phosphine-containing copolyamide is between 1.2 and 2.5; the melting point of the above-mentioned phosphine-containing copolyamide is between 210 and 270°C.

[0027] The preparation method of producing above-mentioned phosphine-containing copolyamide / nanometer montmorillonite flame-retardant composite material comprises the following steps:

[0028] a) Preparation of hexamethylenediamine ethanol solution: dissolving 50 parts ...

Embodiment 2

[0036] In the phosphine-containing copolyamide / nano-montmorillonite flame-retardant composite material in the present embodiment, the organic montmorillonite of 7 parts by weight is dispersed in the phosphine-containing prepolymer of 7 parts by weight and the phosphine-containing prepolymer of 7 parts by weight. In the phosphine-containing copolyamide synthesized by 86 parts of nylon 66 salt.

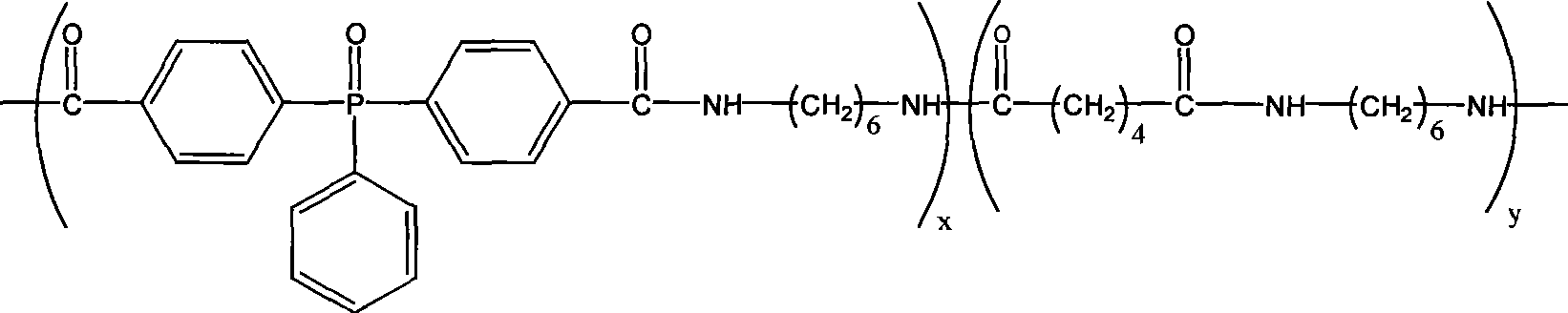

[0037] The polymeric molecular structure of the above-mentioned phosphine-containing copolyamide is

[0038]

[0039] x=1-100; y=1-100.

[0040] The intrinsic viscosity of the phosphine-containing copolyamide is between 1.2 and 2.5; the melting point of the above-mentioned phosphine-containing copolyamide is between 210 and 270°C.

[0041] The preparation method of producing above-mentioned phosphine-containing copolyamide / nanometer montmorillonite flame-retardant composite material comprises the following steps:

[0042] a) Preparation of hexamethylenediamine ethanol solution: dis...

Embodiment 3

[0050] Phosphine-containing copolyamide / nanometer montmorillonite flame-retardant composite material in the present embodiment, its weight part is that 5 parts of organic montmorillonite are dispersed in the phosphine-containing prepolymer of 10 parts by weight and 10 parts by weight of organic montmorillonite with nanoparticles In the phosphine-containing copolyamide synthesized by 85 parts of nylon 66 salt.

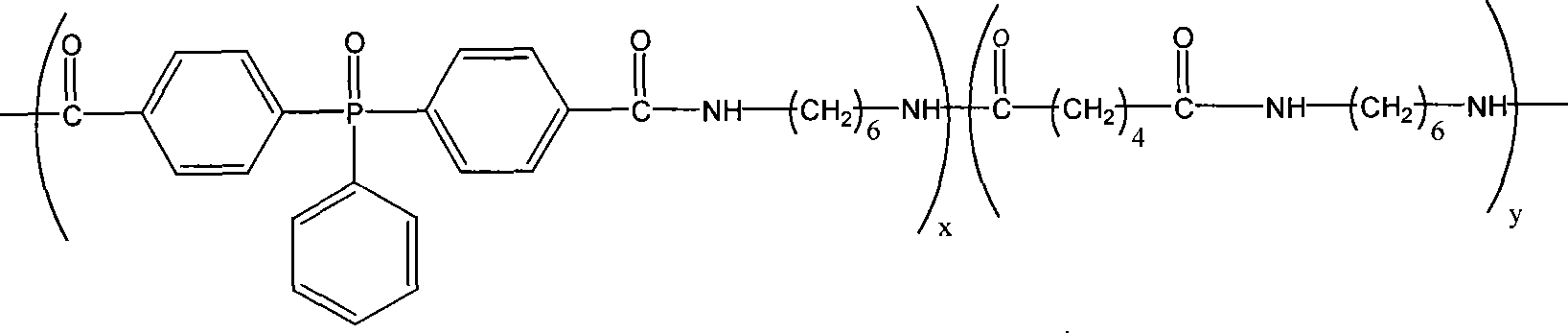

[0051] The polymeric molecular structure of the above-mentioned phosphine-containing copolyamide is

[0052]

[0053] x=1-100; y=1-100.

[0054] The intrinsic viscosity of the phosphine-containing copolyamide is between 1.2 and 2.5; the melting point of the above-mentioned phosphine-containing copolyamide is between 210 and 270°C.

[0055] The preparation method of producing above-mentioned phosphine-containing copolyamide / nanometer montmorillonite flame-retardant composite material comprises the following steps:

[0056] a) Preparation of hexamethylenediamine etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com