Method for processing nitrous oxides in chlorinated exhaust of nitroaromatic compounds

A technology for nitro compounds and aromatic compounds, applied in the fields of energy saving, emission reduction and environmental protection, can solve the problems of high storage risk, low product added value, and difficulty in obtaining solid ammonia salts, etc., and achieve the effect of improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

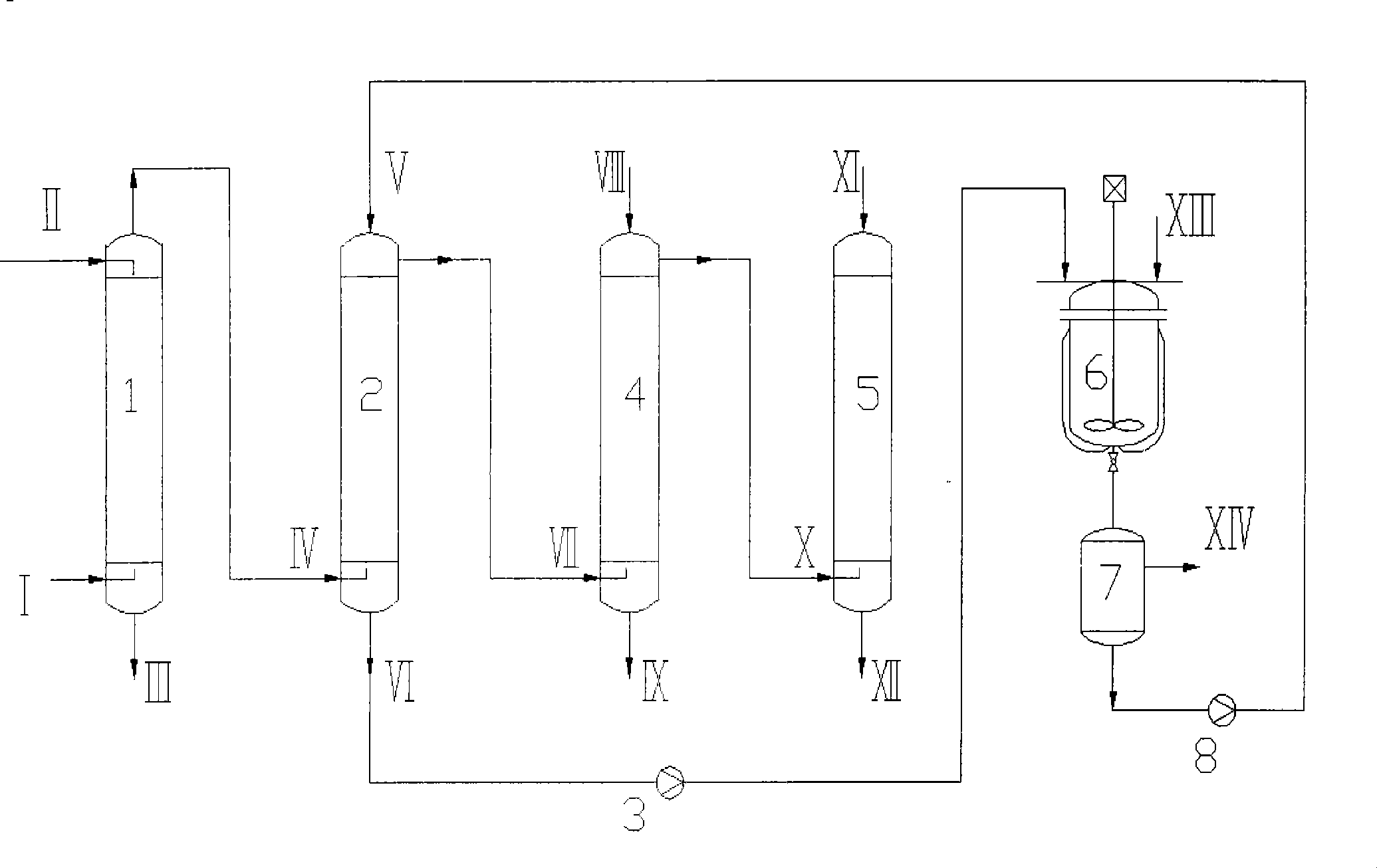

Method used

Image

Examples

Embodiment 1

[0030] The tail gas produced by the chlorination reaction is introduced into the tail gas absorption tower from the top of the chlorination reaction tower. The tail gas is composed of about 26% nitrogen dioxide, 18% nitroxyl chloride and 56% nitrosyl chloride, and 70% is added dropwise to the top of the tail gas absorption tower. Sulfuric acid, the temperature is controlled at about 30°C, the efficiency of absorbing nitrogen oxides is 65%, the content of nitric acid in the absorbed mixed acid is 10%, and the content of nitrous acid is 2%. The tail gas that cannot be completely absorbed is absorbed with water and dilute alkali in sequence to ensure that no harmful gas escapes.

Embodiment 2

[0032] The tail gas produced by the chlorination reaction is introduced into the tail gas absorption tower from the top of the chlorination reaction tower, and the tail gas is composed of about 26% nitrogen dioxide, 18% nitrosyl chloride and 56% nitrosyl chloride, and 80% is added dropwise from the top of the tail gas absorption tower. % sulfuric acid, the temperature is controlled at about 30°C, the efficiency of absorbing nitrogen oxides is 80%, the content of nitric acid in the absorbed mixed acid is 6%, and the content of nitrous acid is 5%. The tail gas that cannot be completely absorbed is absorbed with water and dilute alkali in sequence to ensure that no harmful gas escapes.

Embodiment 3

[0034] The tail gas produced by the chlorination reaction is introduced into the tail gas absorption tower from the top of the chlorination reaction tower, and the tail gas is composed of about 26% nitrogen dioxide, 18% nitrosyl chloride and 56% nitrosyl chloride, and 90% is added dropwise from the top of the tail gas absorption tower. % sulfuric acid, the temperature is controlled at about 30°C, the efficiency of absorbing nitrogen oxides is 90%, the content of nitric acid in the absorbed mixed acid is 6%, and the content of nitrous acid is 12%. The tail gas that cannot be completely absorbed is absorbed with water and dilute alkali in sequence to ensure that no harmful gas escapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com