Composite biological film activated sludge denitrification dephosphorization denitrification method and reactor thereof

A denitrification dephosphorization and activated sludge technology, which is applied in the fields of sewage biochemical treatment and sewage resource utilization, can solve the problems of complex process, difficult operation and management, and high investment in infrastructure, so as to increase biomass and simplify operation and maintenance , the effect of less artificial requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

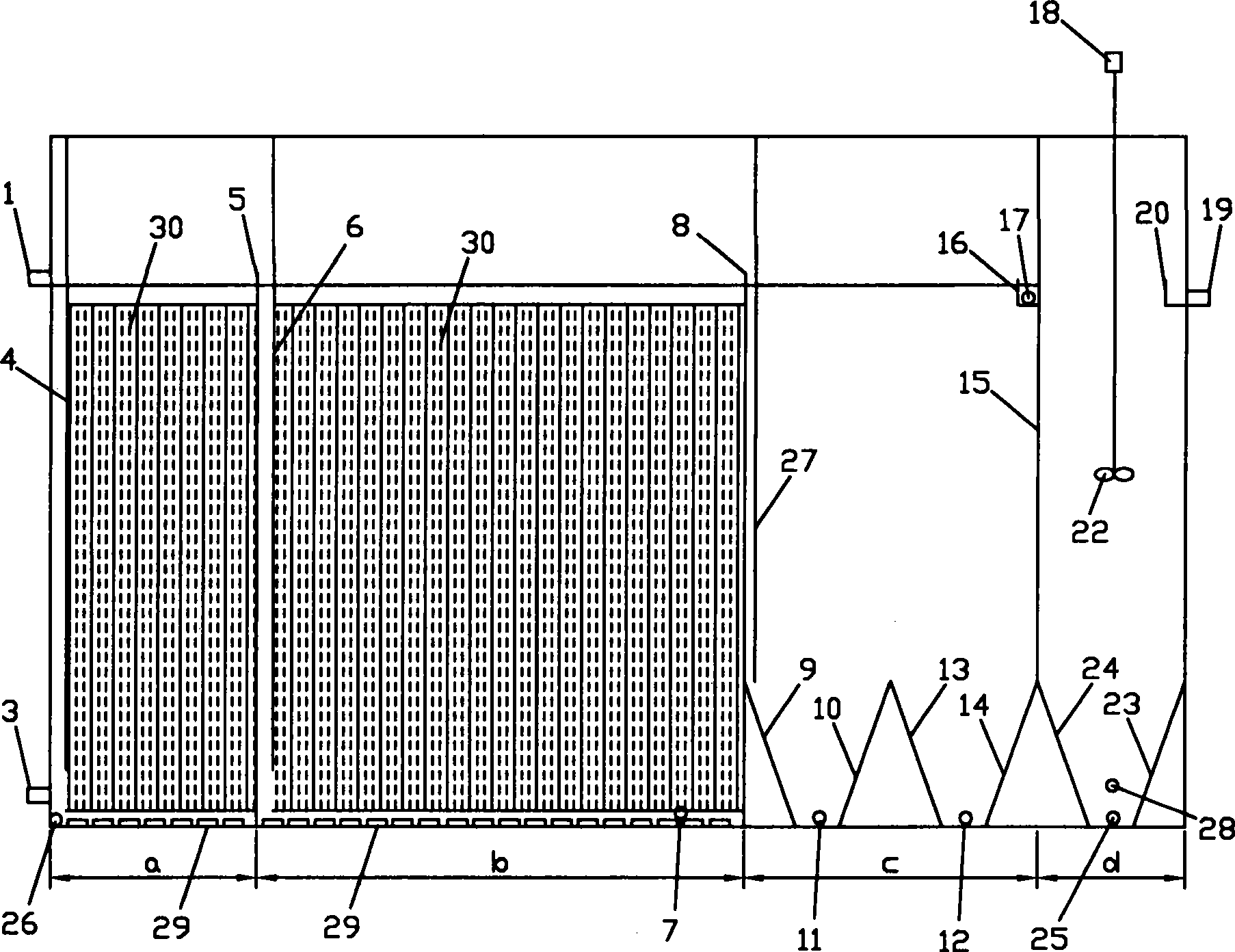

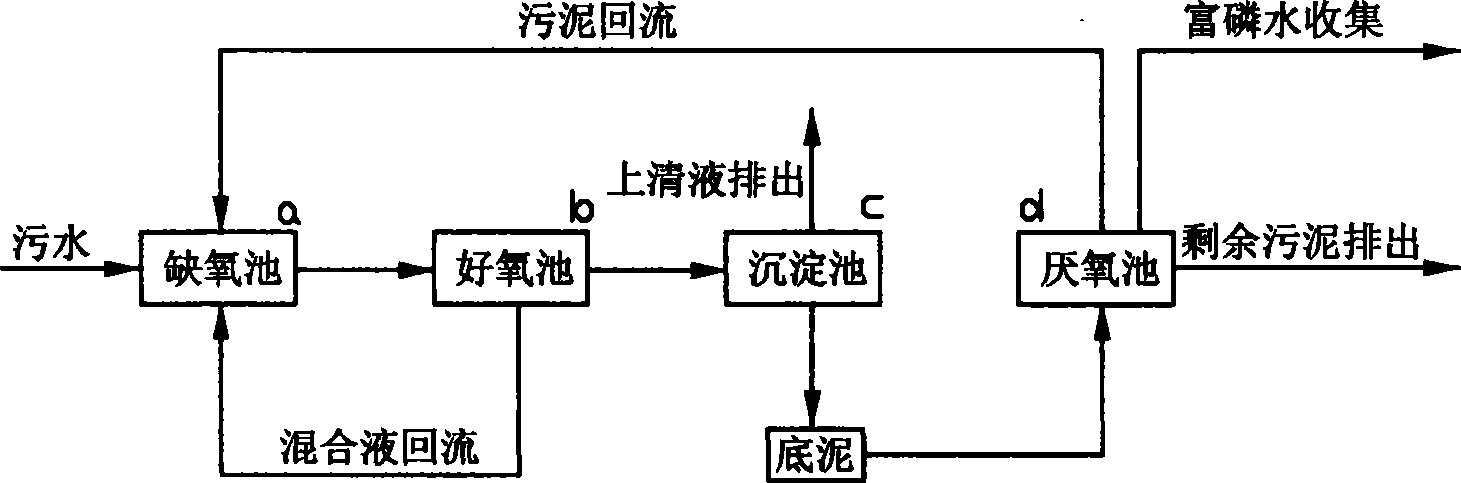

[0047] Using the water inlet pump, the sewage is transported to the anoxic pool a through the sewage inlet, and then the sewage enters the aerobic pool b; the aerobic pool b is equipped with a mixed liquid return device to return part of the mixed liquid to the anoxic pool a, and the rest is mixed The liquid enters the sedimentation tank c for solid-liquid separation, the supernatant is discharged, the bottom sludge enters the anaerobic tank d, part of the sludge is discharged in the form of residual sludge, and part of the sludge is returned to the anoxic tank a, mixed with the influent water, and Phosphorus-rich water collection is performed in the anaerobic pond d. After the phosphorus-rich water is collected, it can be chemically treated, mixed with the influent water, and then re-enter the reactor.

[0048] During the whole running process, keep the water temperature in the composite biofilm activated sludge denitrification denitrification denitrification reactor of the p...

Embodiment 2

[0052] Using the water inlet pump, the sewage is transported to the anoxic pool a through the sewage inlet, and then the sewage enters the aerobic pool b; the aerobic pool b is equipped with a mixed liquid return device to return part of the mixed liquid to the anoxic pool a, and the rest is mixed The liquid enters the sedimentation tank c for solid-liquid separation, the supernatant is discharged, the bottom sludge enters the anaerobic tank d, part of the sludge is discharged in the form of residual sludge, and part of the sludge is returned to the anoxic tank a, mixed with the influent water, and Phosphorus-rich water collection is performed in the anaerobic pond d. After the phosphorus-rich water is collected, it can be chemically treated, mixed with the influent water, and then re-enter the reactor.

[0053] During the whole running process, keep the water temperature in the composite biofilm activated sludge denitrification denitrification denitrification reactor of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com