Nutrition layer material additive for restoring road slope and bare mountain vegetation

A vegetation recovery and nutrient-based technology, applied in the fields of application, botany equipment and methods, soilless cultivation, etc., can solve problems such as impact, negative substrate fertility, and proportional control of burning seeds and seedlings, achieving broad application prospects and saving resources and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1-1

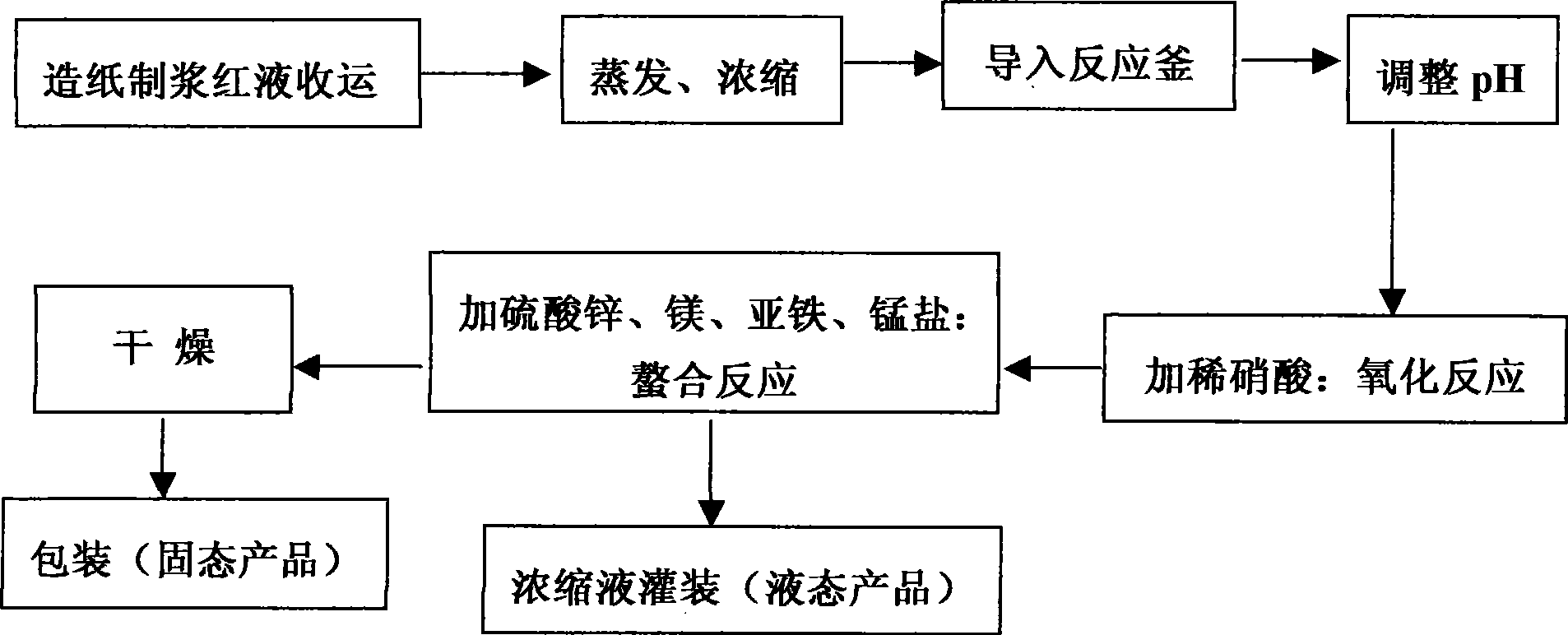

[0030] For the pulping red liquor collected from A paper mill, the pH is 4.8-5.0, and the MVC+MED-TC two-stage combined process is used for evaporation and concentration to a moisture content of 70%.

[0031] The chemical reaction ax was introduced, and the pH value of the concentrated solution was determined to be 3.5. Adjust the pH to 6.0 with slaked lime solution, and add dilute nitric acid with a percentage concentration of 33%, so that the pH of the material in the reactor was 3.0, and the temperature was controlled between 60 and 62°C. Between, stir for 35 minutes, cool.

[0032] Adding 2% zinc sulfate saturated solution, 3% magnesium sulfate saturated solution, 2% ferrous sulfate saturated solution, 3% manganese sulfate saturated solution by volume, reaction temperature control Between 50 and 52°C, stir for 20 minutes.

[0033] The paper-making red liquor lignin mixture processed through the above steps is further dried, and the drying process adopts the flash drying p...

example 1-2

[0035] For the pulping red liquor collected from B paper mill, the pH is 5.0-5.5, and the MVC+MED-TC two-stage combined process is used for evaporation and concentration to a moisture content of 40%.

[0036] Introduce a chemical reaction axe. After measurement, the pH of the concentrated solution is 1.5. Adjust the pH to 5.5 with quicklime, add dilute nitric acid with a percentage concentration of 35%, so that the pH of the material in the reactor is 1.5, and the temperature is controlled between 65 and 67°C. , stirred for 40 minutes, and cooled.

[0037] Add a 5% saturated solution of zinc sulfate by volume, a saturated solution of magnesium sulfate with a volume percentage of 2%, and a saturated solution of ferrous sulfate with a volume percentage of 3%. The reaction temperature is controlled between 55 and 57°C, and stirred for 25 minutes .

[0038] Fill the papermaking red liquor lignin mixture processed through the above steps directly. After testing, the total content ...

example 1-3

[0040] For the pulping red liquor collected from C paper mill, the pH is 5.0-5.5, and the MVC+MED-TC two-stage combined process is used for evaporation and concentration to a moisture content of 50%.

[0041] Introduce a chemical reaction axe. After measurement, the pH of the concentrated solution is 1.5. Adjust the pH to 5.5 with quicklime, add dilute nitric acid with a percentage concentration of 35%, so that the pH of the material in the reactor is 3.5, and the temperature is controlled between 68 and 70°C. , stirred for 30 minutes, and cooled.

[0042] Add 2% zinc sulfate saturated solution, 3% magnesium sulfate saturated solution, 3% ferrous sulfate saturated solution, 2% manganese sulfate saturated solution by volume, reaction temperature control Between 58-60°C, stir for 20 minutes.

[0043] The papermaking red liquor lignin mixture processed in the above steps is further dried, and the drying process adopts a spray drying process. After the drying is completed, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com