Transparent biodegradable polylactic acid nano composite material and preparation thereof

A nano-composite material and biodegradation technology, applied in the field of polyester nano-composite material and its preparation, can solve the problems of opacity, reduced transparency of polylactic acid, disadvantage, etc., and achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0040] A, premixing: take the material according to the proportioning of the weight portion of the embodiment 1-3 in table 1 and the technical index of explanation, put into the high-speed mixer and stir evenly; the speed of the high-speed mixer is 300 rpm;

[0041] B. Mixing: Put the above-mentioned uniformly stirred materials into an ordinary internal mixer, 175°C, 60 rpm, and mix for 5 minutes;

[0042] C. Hot press molding: hot press the above kneaded product at 190° C. and a pressure of 10 MPa to form a sheet with a thickness of 1.0 mm to obtain a transparent and fully biodegradable polylactic acid nanocomposite material.

[0043] Cut the sheet into dumbbell-shaped specimens, the thin neck part of which is 20 mm long and 4 mm wide, for tensile testing; cut it into square samples with a side length of 20 mm for light transmittance and haze testing. The mechanical properties and transparency measured according to the different compositions of the samples are shown in Table ...

Embodiment 4-7

[0045] A, premixing: take the material according to the proportioning of the weight portion of the embodiment 4-7 comparative example in Table 1 and the technical index of explanation, put into the high-speed mixer and stir evenly; the high-speed mixer rotating speed is 300 rev / min;

[0046] B. Mixing: Put the above-mentioned uniformly stirred materials into an ordinary internal mixer, 175°C, 60 rpm, and mix for 5 minutes;

[0047] C. Hot press forming: hot press the above kneaded product at 190° C. and a pressure of 10 MPa to form a 1.0 mm thick sheet to obtain a transparent and fully biodegradable polylactic acid nanocomposite material.

[0048] Cut the sheet into dumbbell-shaped specimens, the thin neck part of which is 20 mm long and 4 mm wide, for tensile testing; cut it into square samples with a side length of 20 mm for light transmittance and haze testing. The mechanical properties and transparency measured according to the different compositions of samples are shown i...

Embodiment 8

[0050] A, premixing: take the material according to the proportioning by weight of Example 8 in Table 1 and the technical index of explanation, put into high-speed mixer and stir evenly; The speed of high-speed mixer is 300 rev / min;

[0051] B. Mixing: Put the above-mentioned uniformly stirred materials into an ordinary internal mixer, 170°C, 60 rpm, and mix for 3 minutes;

[0052] C. Hot press molding: hot press the above kneaded product at 190° C. and a pressure of 10 MPa to form a sheet with a thickness of 1.0 mm to obtain a transparent and fully biodegradable polylactic acid nanocomposite material.

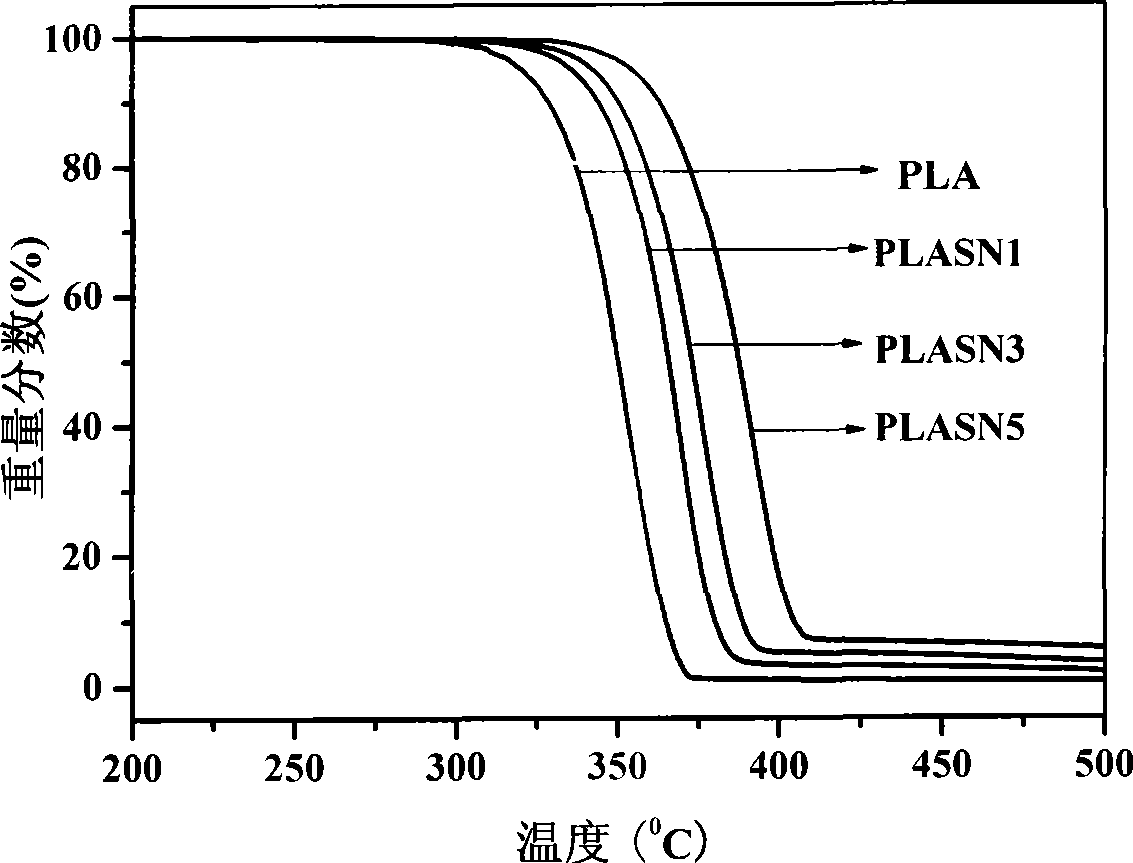

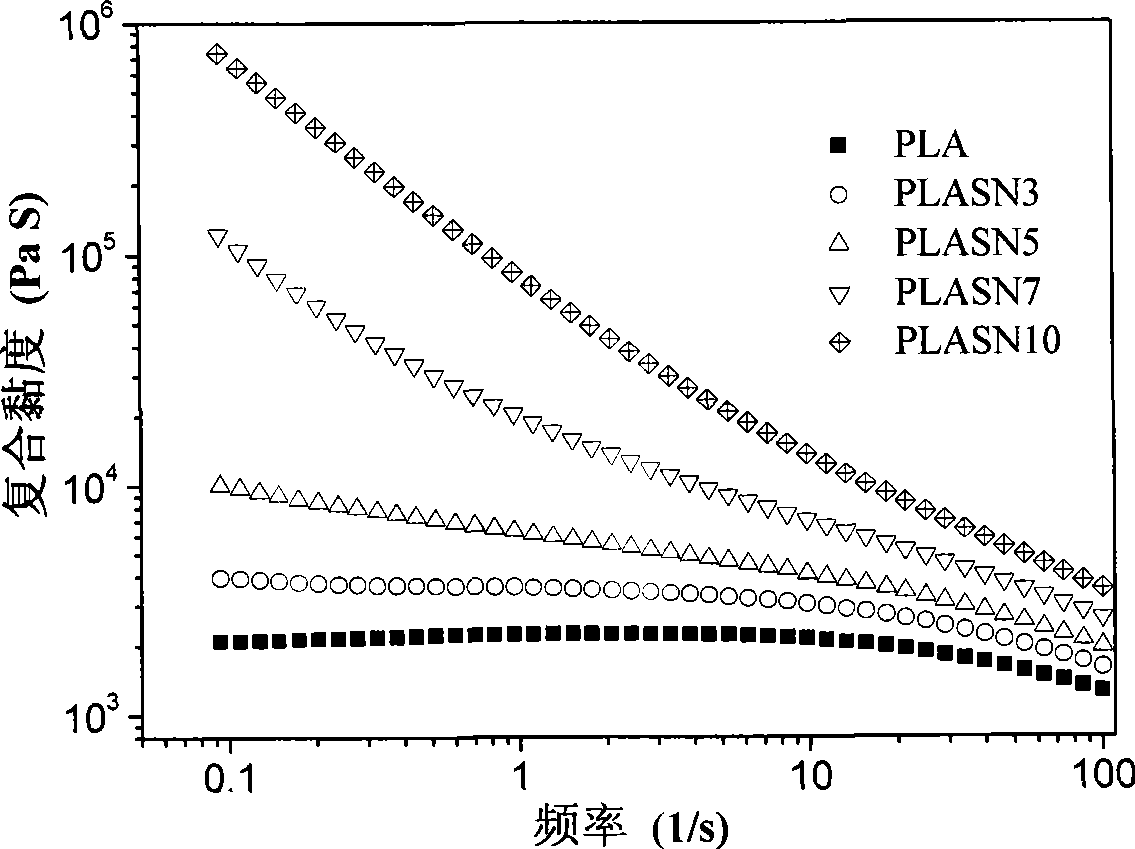

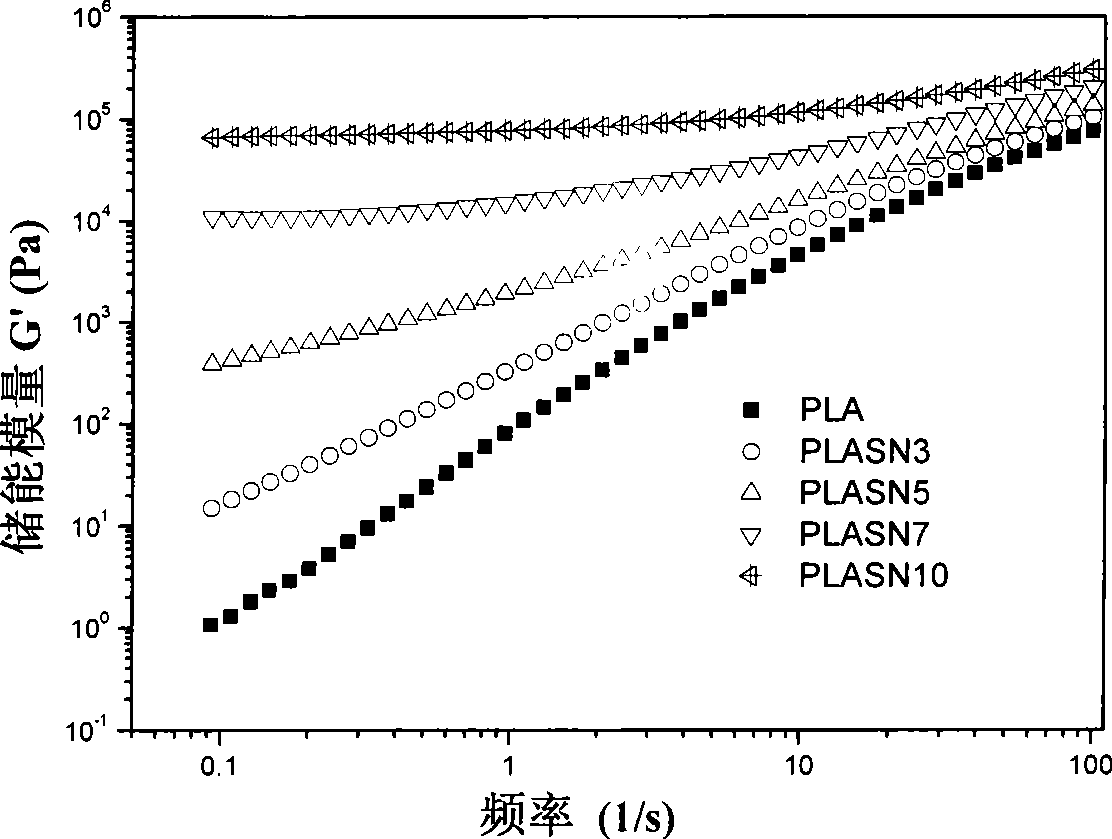

[0053] Cut the sheet into dumbbell-shaped specimens, the thin neck part of which is 20 mm long and 4 mm wide, for tensile testing; cut it into square samples with a side length of 20 mm for light transmittance and haze testing. The mechanical properties and transparency measured according to the composition of the samples are shown in Table 2, and the rheological properties ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com