Microwave absorbing material with periodic nanostructure and preparation thereof

A technology of microwave absorbing materials and nanostructures, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult adjustment of electromagnetic parameters of microwave absorbers, heavy weight, weak absorption attenuation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

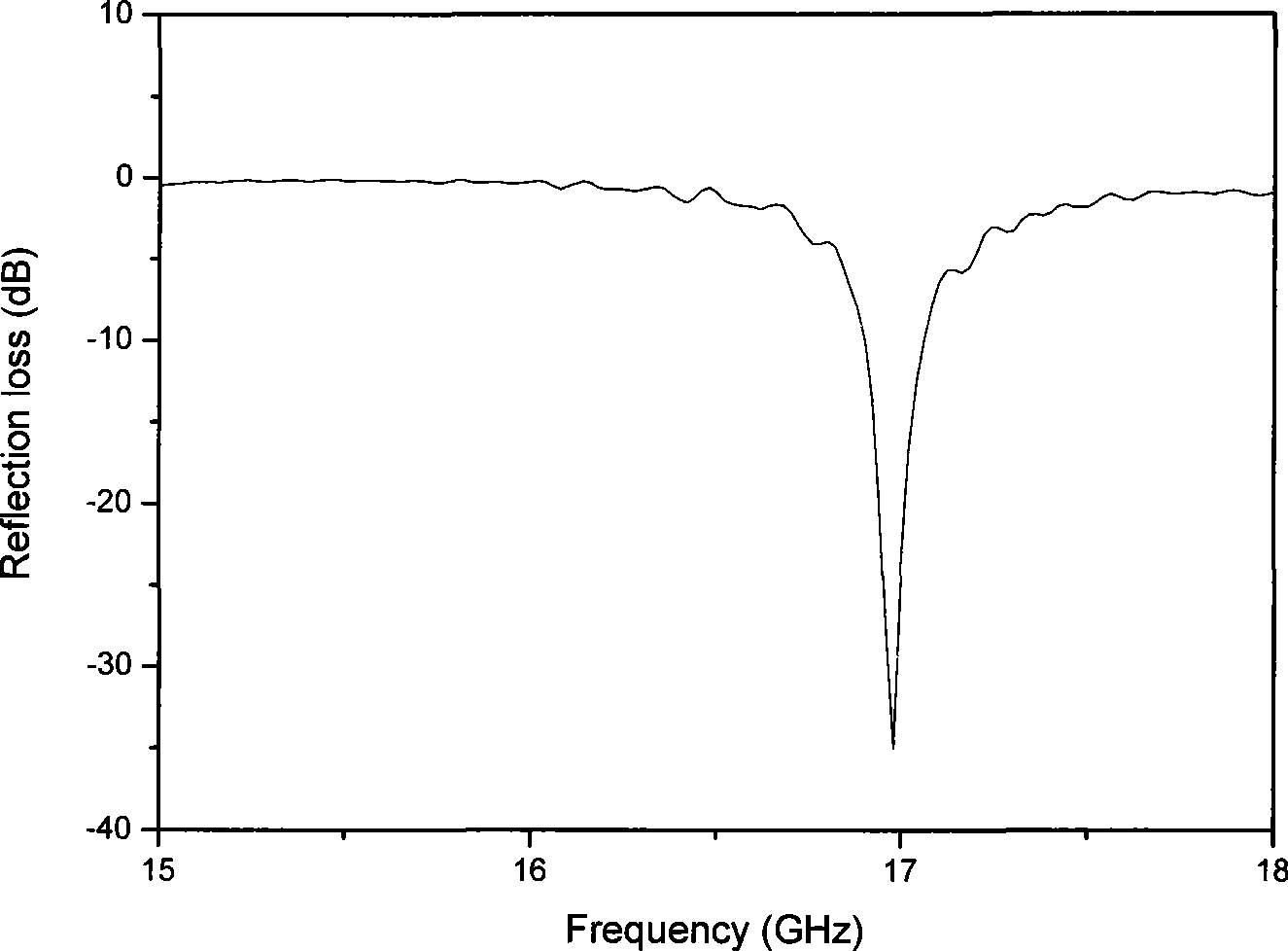

Image

Examples

Embodiment 1

[0019] ①Preparation of sol precursor solution: add 0.1 mol of divalent metal iron salt and 0.2 mol of trivalent metal iron salt into 50 ml of water, stir evenly, add 0.13 mol of organic acid into it, and after fully stirring, use Concentrated ammonia water adjusts the pH value of the solution to neutral, then adds 1.5 moles of urea, stirs, and when it is completely dissolved, under the protection of nitrogen, heat the above solution in an oil bath to 80 degrees Celsius and keep it for 2 hours to obtain a sol precursor solution .

[0020] ② Anneal the aluminum sheet for 10 hours at 500 degrees Celsius. After taking it out, use 85% phosphoric acid with mass fraction, 68% concentrated nitric acid by mass fraction, and water to make a mixed solution at a volume ratio of 8:1:1. After chemical polishing until the surface is bright, aluminum sheet is used as an anode, electrochemically corroded in an oxalic acid solution of 0.4 mol / L at 5 degrees Celsius and a voltage of 40 volts for 12 ...

Embodiment 2

[0024] In step ③, the oil bath is heated to 160 degrees Celsius and kept for 5 hours

[0025] The other steps are the same as in Example 1.

Embodiment 3

[0027] ①Preparation of the sol precursor solution: add 0.05 moles of divalent metal iron salt, 0.2 moles of trivalent metal iron salt and 0.05 moles of cobalt metal salt into 50 ml of water, stir well, add 0.3 moles of organic acid to it After fully stirring, adjust the pH value of the solution to neutral with concentrated ammonia water, then add 5 moles of urea, stir, after it is completely dissolved, under the protection of argon, heat the above solution in an oil bath to 80 degrees Celsius and keep it warm for 2 Hours to obtain a sol precursor solution.

[0028] The other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com