Single-slice integrated micro-lens and its production method

A technology of micro-lens and monolithic integration, which is applied to the structural details of lenses, lasers, and semiconductor lasers, etc., can solve problems such as harsh processing conditions, inconspicuous optical coupling performance, and poor control of lens shape, and achieve improved integrity. Excellent performance and reliability, good collection effect, and complete lens shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

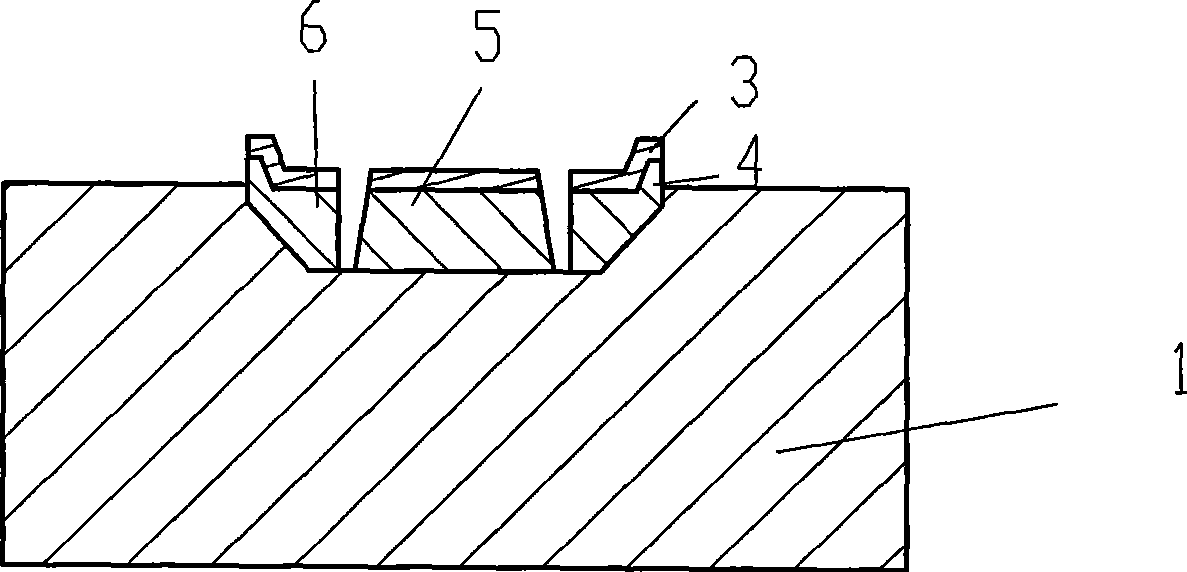

[0021] The present invention is described in further detail below in conjunction with accompanying drawing:

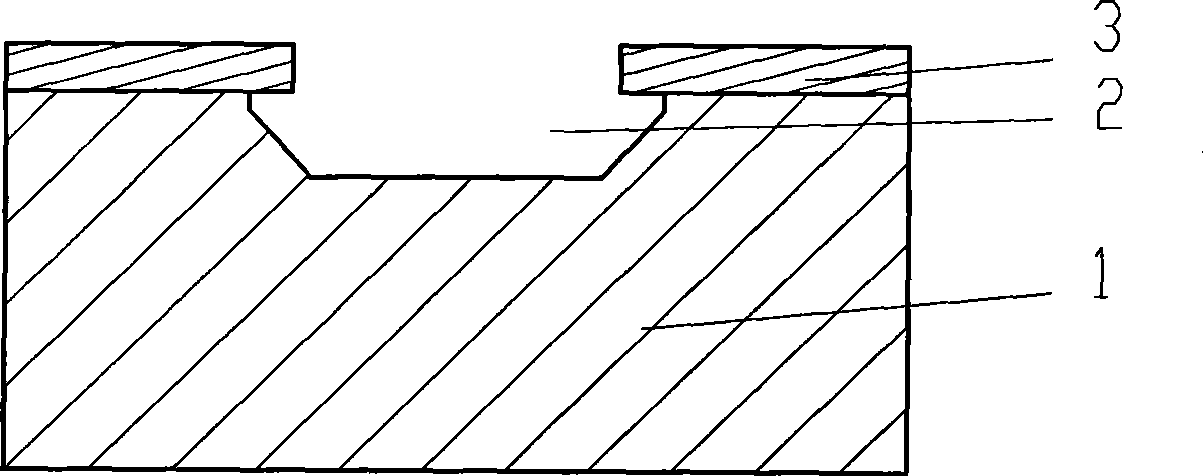

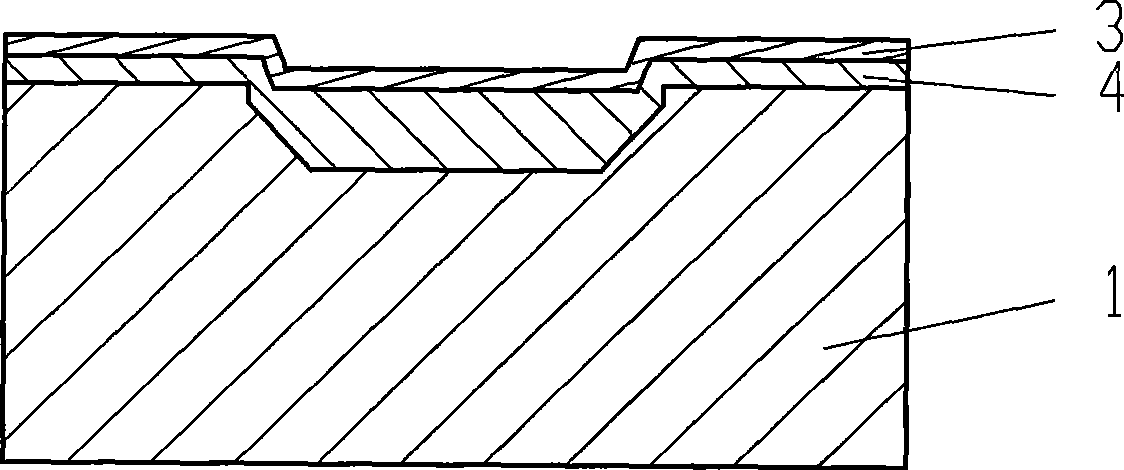

[0022] Such as figure 1 As shown, on an InP substrate 1, a pit 2 is etched by a wet etching process with a photoresist 3 as a mask.

[0023] The area and depth of the pits are adjusted according to the characteristics of the microlens.

[0024] The wet etching process adopts isotropic HBr, H 2 o 2 and H 2 O mixed solution, its volume ratio is 1:1:9, at room temperature (25°C), the corrosion rate is about 2 μm / min.

[0025] The pits can also be made by plasma dry etching process. Apply ICP etching equipment to adjust the reaction gas Cl 2 / CH 4 / H 2 The flow ratio is 7sccm:8sccm:5.5sccm, the incident power of radio frequency is 200W, the air pressure in the reaction chamber is 4-5mTorr, and a circular or square pit is made. By adjusting the reaction gas Cl 2 / CH 4 / H 2 The ratio of the ratio and the incident power of radio frequency and the air pressure in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com