Enzymatic reaction black garlic fermentation method and special device

A technology for enzymatic reaction and fermentation of black garlic, applied in application, food preparation, food science and other directions, can solve the problems of inability to see the inside of the outer skin, trouble for consumers to take, and inability to mass-produce, and achieves shortened processing time and simple structure. , the effect of simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

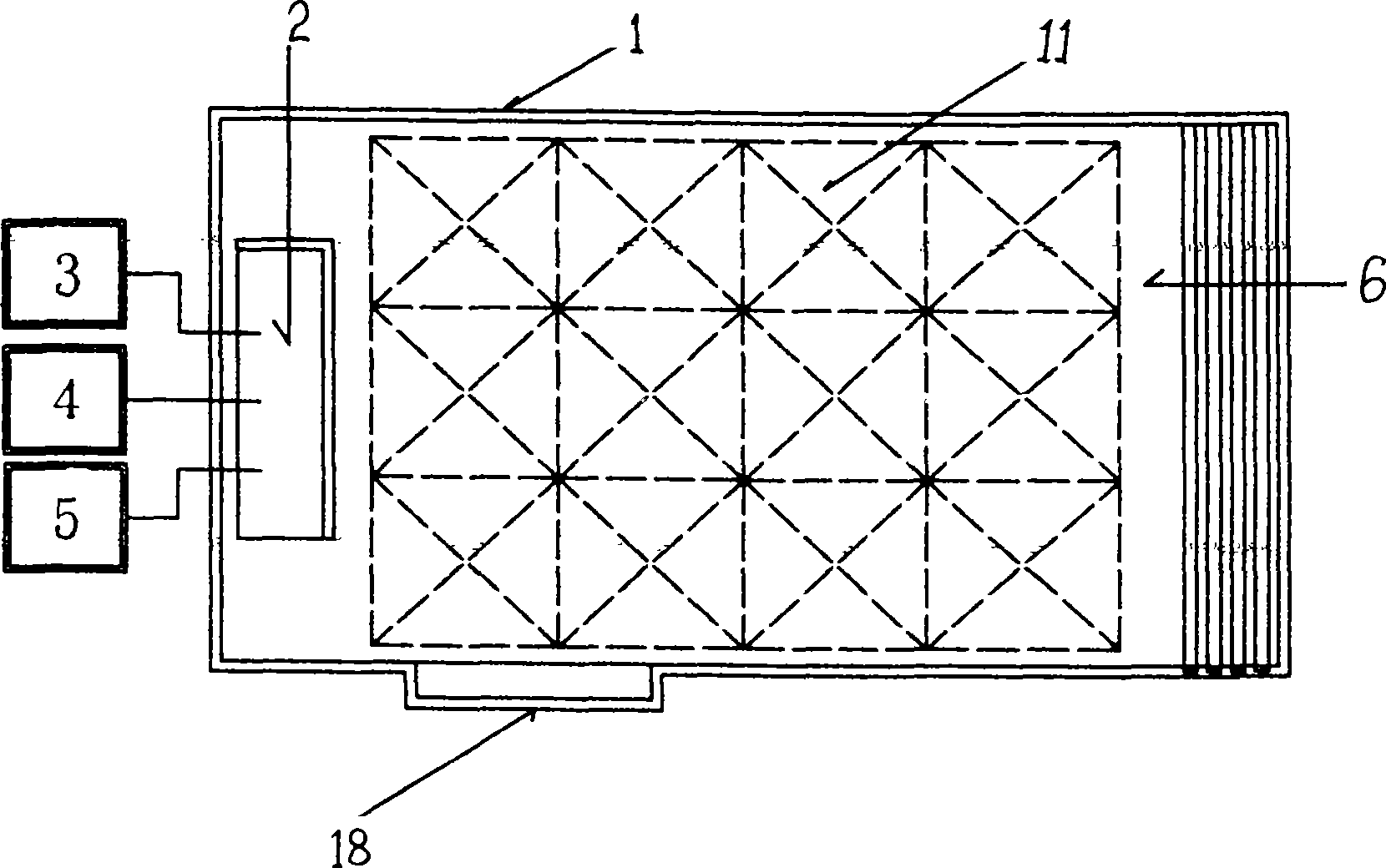

[0026] use as Figure 2-6 The fermentation chamber shown in the figure carries out enzymatic fermentation and processing of black garlic. One side of the fermentation chamber 1 is provided with a heat exchanger assembly 2, and the other side is provided with an adjustment device consisting of an air direction adjustment plate 6 and an air direction adjustment plate frame 14. The heat exchange The heat exchanger assembly 2 includes an assembly frame 16, a first heat exchanger 7 is arranged in the heat exchanger assembly frame, and an air circulation fan 10 is installed on the lower part of the first heat exchanger, and a heating element is installed in the assembly frame 16 as required. The cooling exchanger 8 is constructed with concrete on the ground of the fermentation chamber 1. The second heat exchanger 9 is set under the concrete floor 17. The outside of the fermentation chamber near the heat exchanger assembly is provided with a first heating device 3, a second heating de...

Embodiment 2

[0030] The original product of black garlic obtained in Example 1 is pushed back into the fermentation chamber for drying. The calculation of the drying time is to start the second heater, and calculate the temperature rise of the fourth stage set temperature value. The fourth stage set the temperature It is 30°C, and the set time is 10-20 hours. After the heating device stops, open the access door and push the fermentation rack out of the fermentation room to obtain semi-dried black garlic.

Embodiment 3

[0032] Add purified water 4-5 times the weight of black garlic to the original product of black garlic obtained in Example 1, heat to 98-103°C, heat-preserve and extract for 3-8 hours; centrifuge the solid-liquid and collect the filtrate to obtain the black garlic extract .

[0033] Example 3

[0034] The enzymatically fermented black garlic raw product obtained in Example 1 was freeze-dried, and then crushed into powder to obtain black garlic powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com