Preparation method of inorganic calcium phosphate salt/biodegradable polymer fiber film composite material

A biodegradable, calcium phosphate technology, applied in medical science, prosthesis, etc., can solve the problem that the biological activity and remineralization of calcium phosphate cannot be fully exerted, affect the morphology of composite fibers, the mechanical properties of orientation degree, and cannot be controlled. The distribution of mechanical properties in space of composite materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0024] A kind of embodiment of the present invention is, a kind of preparation method of inorganic calcium phosphate salt / biodegradable polymer fiber film composite material, and its method is:

[0025] Prepare polylactic acid fiber film with a thickness of 100 μm by electrospinning polylactic acid, and collect it with a high-speed roller with a line speed of 16.7m / s to obtain a polylactic acid oriented fiber film with a fiber orientation degree of more than 80%; soak the oriented fiber film In 2mg / mL gelatin / phosphate buffer, react at 2-4°C for 24 hours, after washing, the gelatin grafting amount is 0.02nmol / cm 2 The polylactic acid oriented fiber membrane; then mineralized in vitro, that is, soaking it in human simulated body fluid with a concentration of 1.5 times, soaking it for 7 days at 37°C, taking it out and cleaning it, and obtaining nano inorganic calcium phosphate / biodegradable polylactic acid Composite oriented fiber film, wherein the low crystalline calcium phosph...

Embodiment 2

[0028] Prepare polylactic acid fiber membranes with a thickness of 75 μm by electrospinning polylactic acid, and use a high-speed roller with a line speed of 16.7m / s to collect polylactic acid oriented fiber membranes with a fiber orientation of more than 80%; soak the oriented fiber membranes In 2mg / mL gelatin / phosphate buffer, react at 2-4°C for 24 hours, after washing, the gelatin grafting amount is 0.02nmol / cm 2 Polylactic acid oriented fiber membrane; then in vitro mineralization, that is, immersing it in 1.5 times the concentration of human simulated body fluid, immersing it at 37 ° C for 7 days, taking it out and cleaning it, and obtaining nano inorganic calcium phosphate / biodegradable polymer Lactic acid composite oriented fiber film, wherein the low crystalline calcium phosphate content is 15.1% (the preparation method of the polylactic acid composite oriented fiber film of this example is the same as that of Example 1).

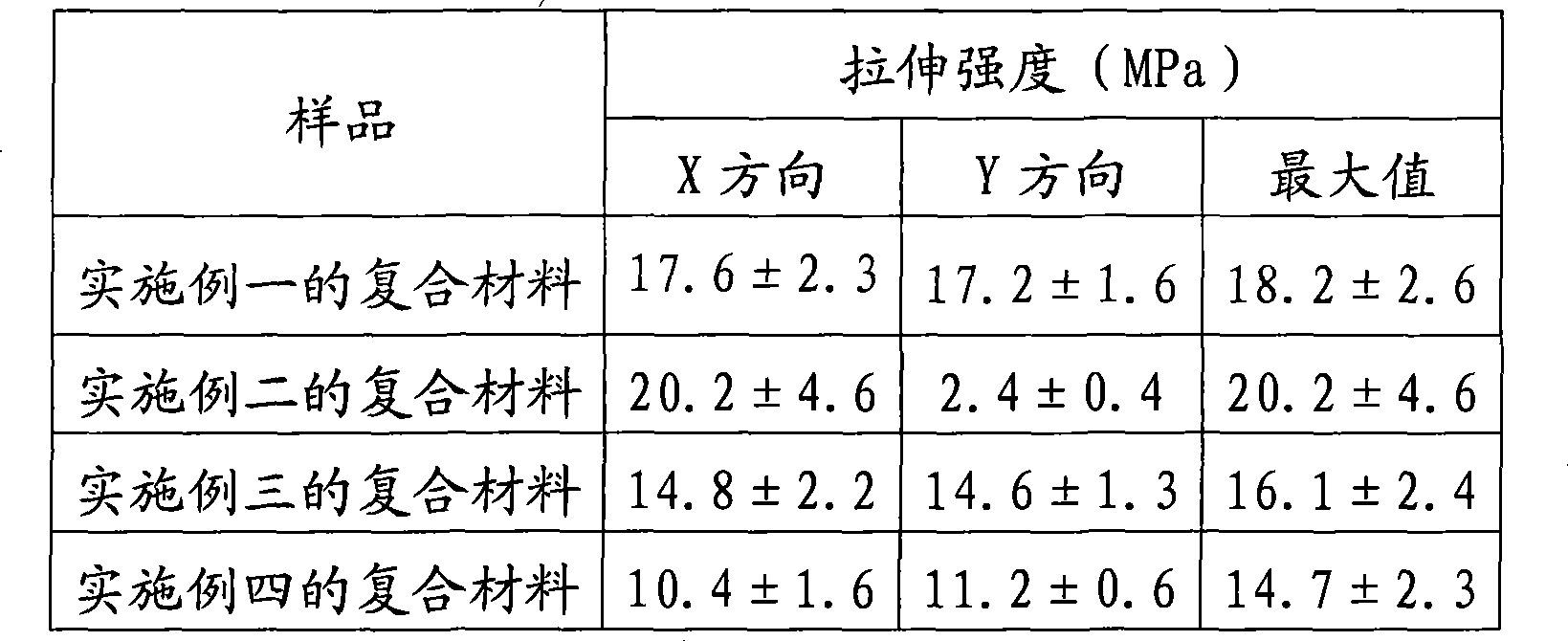

[0029] 8 layers of composite fiber membranes ...

Embodiment 3

[0031] This embodiment is basically the same as Embodiment 2, the difference is only:

[0032] Polylactic acid fiber membranes with a thickness of 150 μm were prepared by electrospinning.

[0033] Four layers of composite fiber membranes with a thickness of 150 μm were superimposed and arranged according to the fiber orientation angle between adjacent layers at 45°, and then subjected to hot-pressing treatment to obtain a composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com