Process and apparatus for preparing methanal with low transformational cycle method

A technology for the preparation and preparation of formaldehyde, which is applied in the direction of organic chemistry, can solve the problems of increased quantity, and achieve the effects of low conversion, high quality, and reduced operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

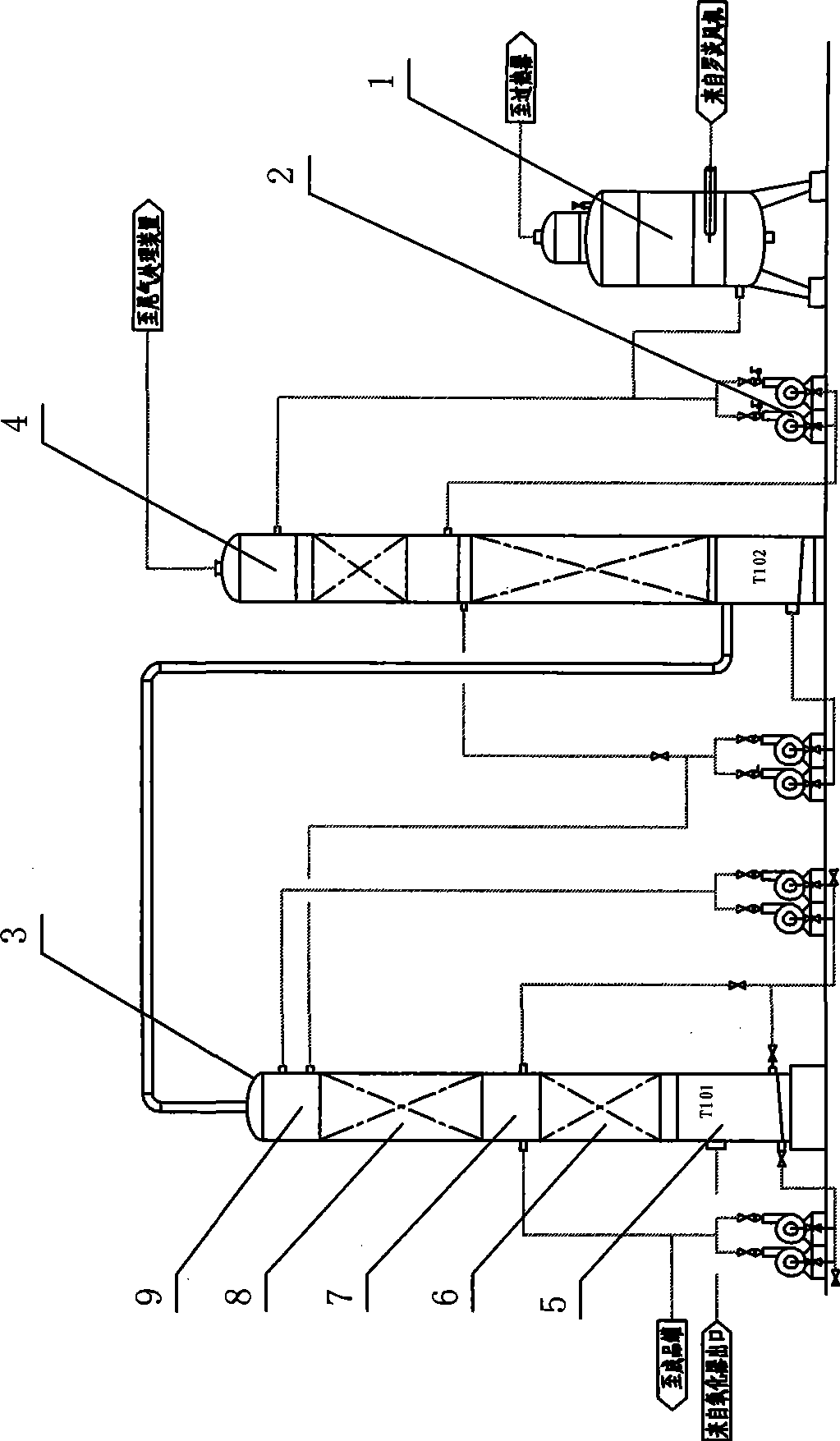

[0024] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

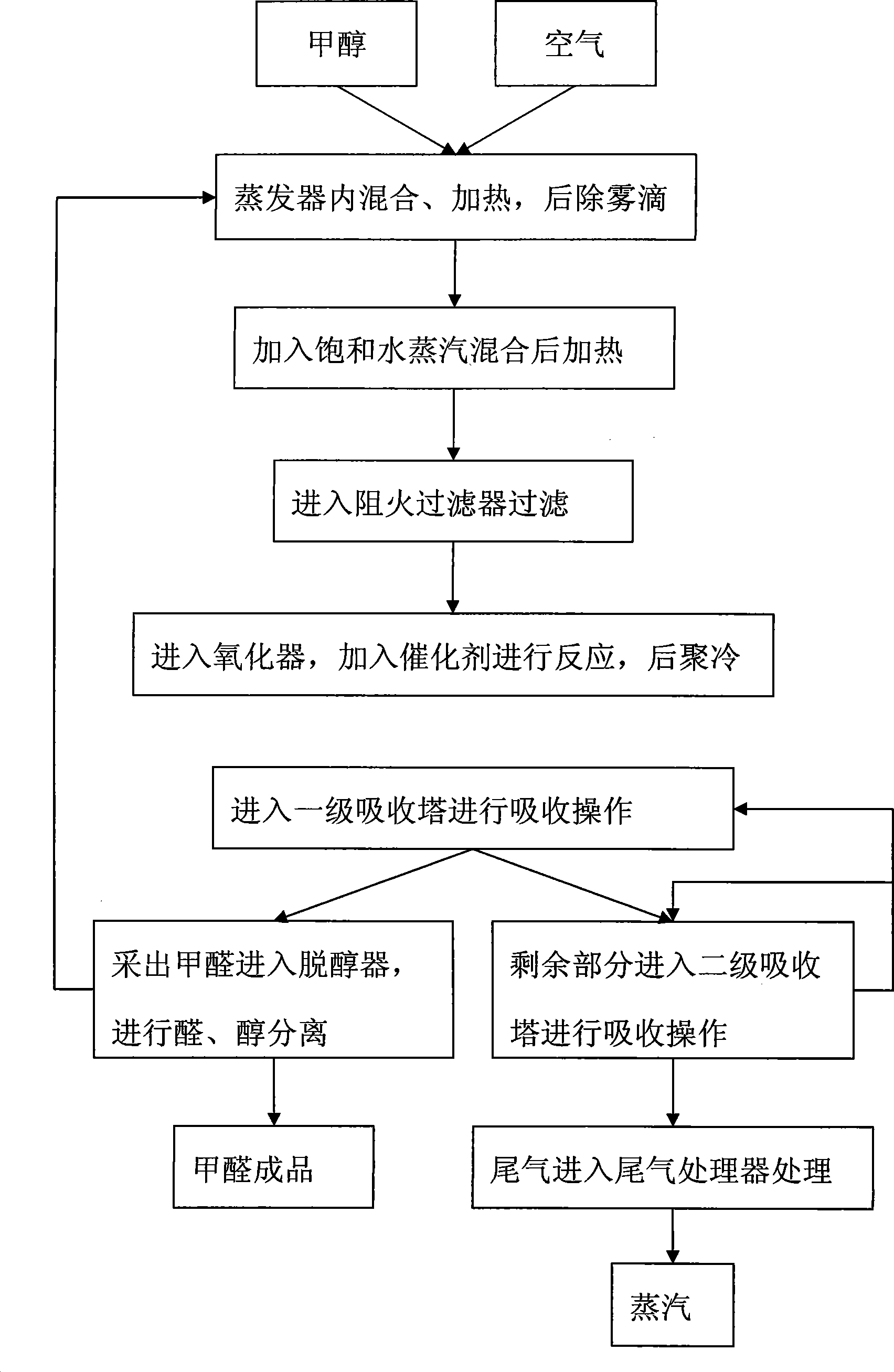

[0025] Such as figure 1 The formaldehyde preparation technology of the best embodiment shown, its technological process is as follows

[0026] (1) methanol and air are mixed in a ratio of 0.38 to 0.45 according to the oxygen-alcohol molar ratio;

[0027] (2) heating the binary mixture of methanol and air, and demistering the heated mixture;

[0028] (3) adding saturated steam to the mixture of methanol and air;

[0029] (4) Heating the ternary mixture of methanol, air and water vapor to between 100°C and 120°C, and then performing fire-stop filtration;

[0030] (5) The ternary mixture is fed with a catalyst, and the mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com