Continuous production method for 4,6-dinitryl o-sec-butylphenol inhibitor

A technology of o-sec-butylphenol and polymerization inhibitor, applied in 4 fields, can solve problems such as increased production risk, and achieve the effect of reducing the number of operators, reducing the influence of human factors, and reducing the size of the reaction equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

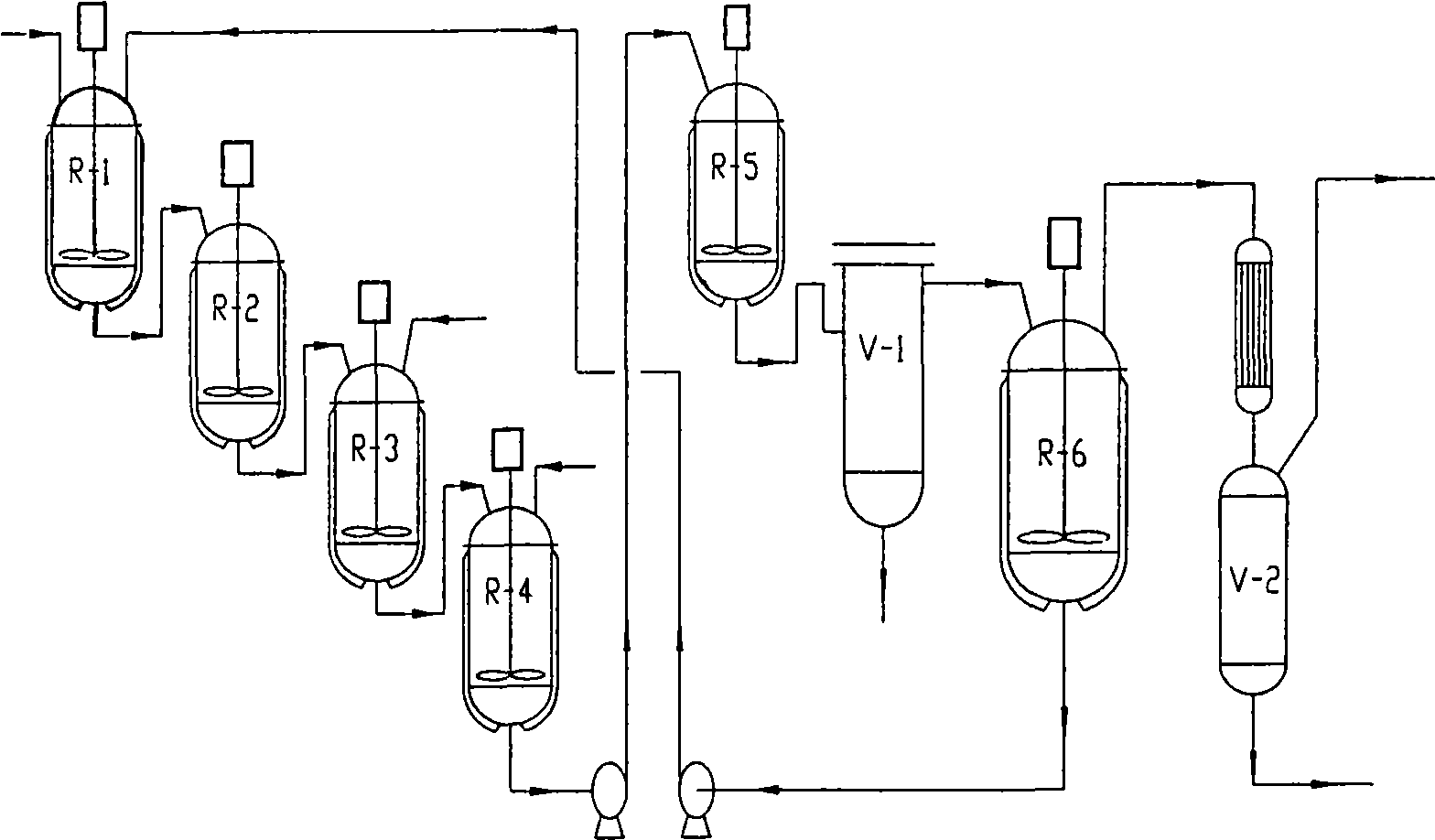

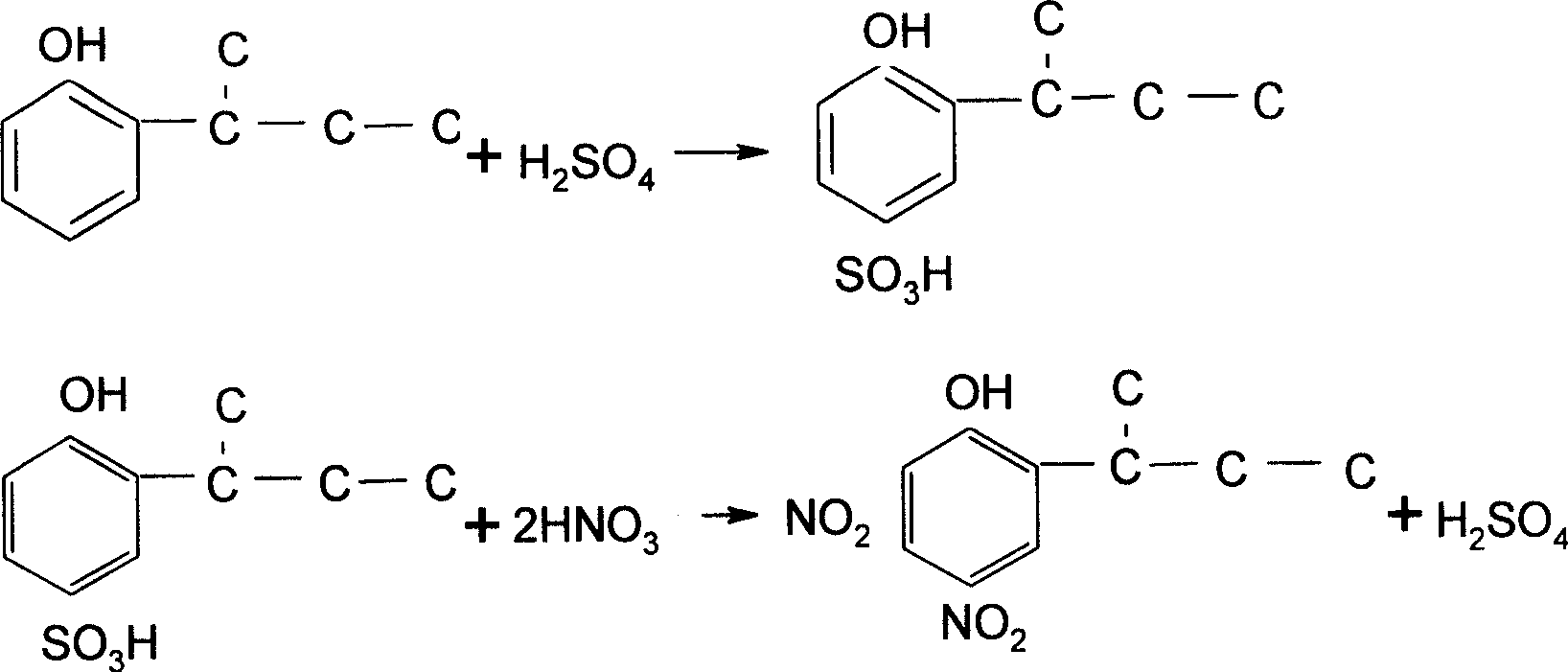

[0023] Connect 5 small enamel kettles of 100-500L in series by utilizing the potential difference, and the reaction materials o-sec-butylphenol, sulfuric acid, and nitric acid are set at a molar ratio of sulfuric acid to o-sec-butylphenol of 1:1.2-1.4, nitric acid and o-sec The butylphenol molar ratio is 1:2.2-3.2, and the amount is continuously added to the reactor equipment in sequence through the metered flow rate, and the temperature is controlled by the ice-salt water vapor. 97%-98% o-sec-butylphenol passes through the flowmeter at 0.10-0.25m per hour 3 Enter the R-1 sulfonation tank, and at the same time, 70%-90% sulfuric acid flows at 0.05-0.125m per hour 3 Enter the R-1 sulfonation tank for sulfonation reaction, the temperature is controlled at 40-60°C. It flows into the R-2 sulfonation tank through the potential difference for further reaction, and the temperature is controlled at 70-90°C. Flow into the R-3 tank through the potential difference, and at the same time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com