Closed type hydraulic transmission for heliostat of solar thermal power generation system

A hydraulic transmission device, solar thermal power generation technology, applied in the direction of solar thermal power generation, mechanical power generated by solar energy, fluid pressure actuation device, etc., can solve the problems of poor control reliability, large installation space, low efficiency, etc., and achieve reliability Improvement, low manufacturing cost and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

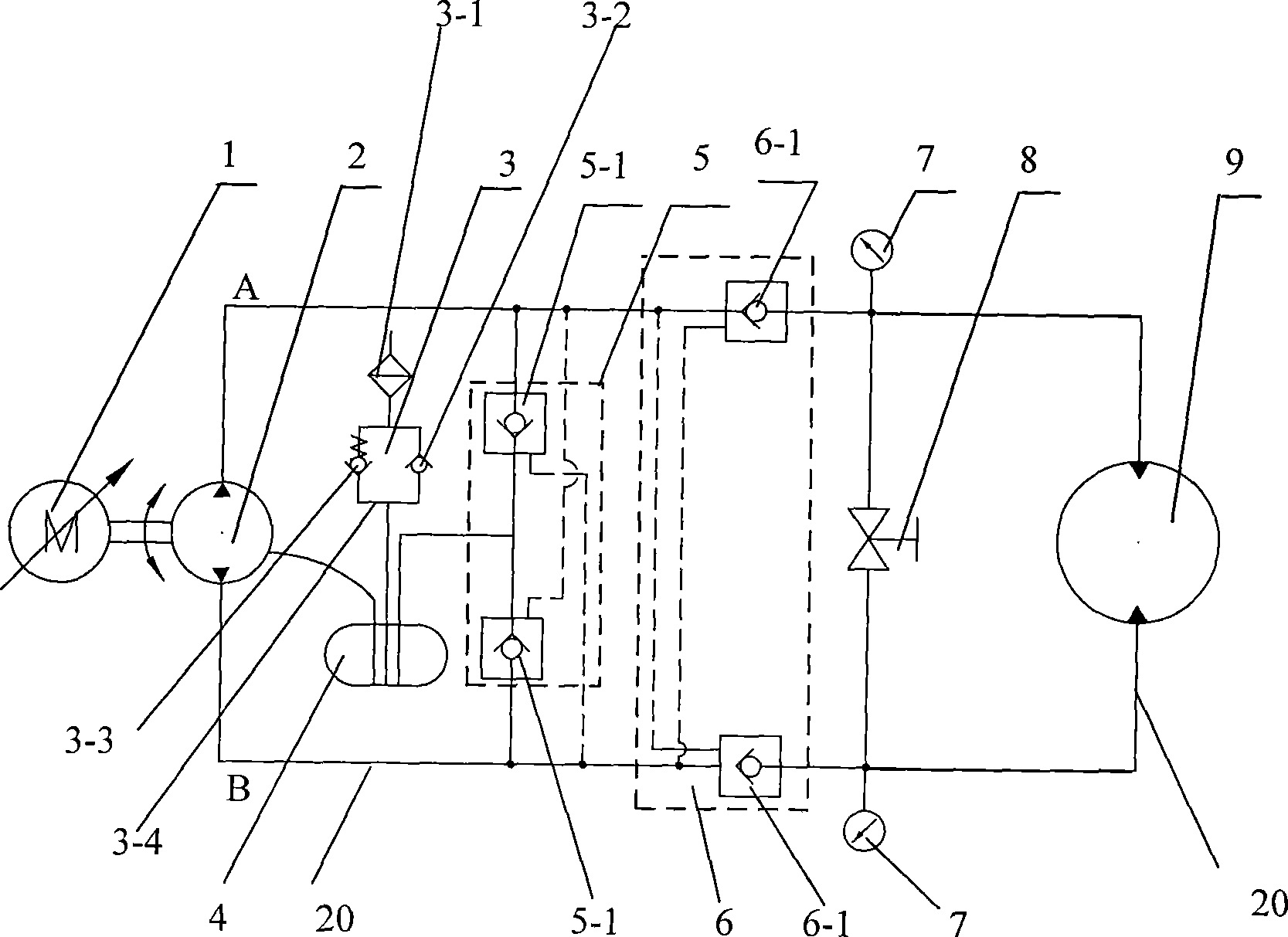

[0009] Specific implementation mode one: as figure 1 As shown, the closed hydraulic transmission device used on the heliostat of the solar thermal power generation system described in this embodiment includes an AC servo motor or a frequency conversion motor 1, a bidirectional quantitative pump 2, a pre-pressed air filter 3, a sealed Pressure oil tank 4, replenishment valve assembly 5, two-way hydraulic lock assembly 6 and swing hydraulic motor 9, the AC servo motor or frequency conversion motor 1 is connected to the two-way quantitative pump 2 through a coupling, and the two-way quantitative pump 2 is connected to the swing A closed circuit 20 is formed between the hydraulic motors 9, the oil discharge port of the two-way quantitative pump 2 communicates with the sealed pressure oil tank 4, the pre-pressurized air filter 3 communicates with the sealed pressure oil tank 4 through the oil pipe, and the oil supply valve assembly 5 is connected in parallel on the closed circuit 2...

specific Embodiment approach 2

[0010] Specific implementation mode two: as figure 1 As shown, the pre-pressurized air filter 3 in this embodiment is composed of an air filter 3-1, an intake check valve 3-2 and an exhaust check valve 3-3, and the intake check valve 3-2 and the exhaust one-way valve 3-3 are connected in parallel through the oil pipe to form the circuit 3-4, the air filter 3-1 is connected in series with one end of the circuit 3-4, and the other end of the circuit 3-4 is connected with the closed pressure oil tank 4 connected. A pre-pressurized air filter 3 is installed on the airtight pressure oil tank 4 to ensure that the airtight pressure oil tank has a certain positive pressure. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: as figure 1 As shown, the replenishment valve assembly 5 in this embodiment is composed of two plug-in hydraulic control check valves 5-1 butted together. The oil supply valve assembly 5 composed of two plug-in hydraulic control check valves 5-1 connected in series is connected in parallel in a closed circuit, which can reliably ensure that the oil suction port of the quantitative pump is connected to the (small) sealed pressure oil tank 4 The hydraulic oil is communicated to compensate the leakage of the two-way quantitative pump 2 and the swing hydraulic motor 9, to ensure that the pressure in the low-pressure pipeline (oil pipe) is greater than the air separation pressure, and to prevent cavitation and air infiltration. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com