Recovering experimental method for detecting amino acid content in milk and milk products

A recovery experiment, amino acid technology, applied in the recovery experiment of amino acid content detection in milk and dairy products, the detection field of milk and dairy products, can solve problems such as failure, free amino acid damage, loss, etc., to achieve accurate and reliable results, Simple operation and high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

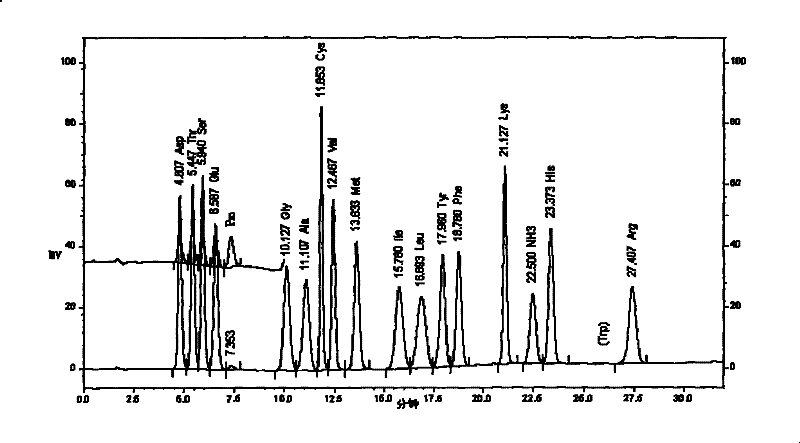

[0032] Example 1 Detection and recovery experiment of 17 kinds of amino acids in pure milk.

[0033] 1. Detection of amino acid content in pure milk:

[0034] (1) Prepare amino acid mixed standard solution.

[0035] Take amino acid mixed standard solution 0.4ml (produced by Ajinomoto Co., Ltd. in Japan, various amino acid mixed standard solution in 0.1mol / L HCl solution, its concentration is 2.50 μ mol / ml, wherein proline is 5.0 μ mol / ml), use 0.02mol / L hydrochloric acid solution was dissolved and the volume was adjusted to 10ml, and a 2nmol / 20uL (2 nanomoles per 20 microliters) amino acid mixed standard working solution was prepared, in which proline was 4nmol / 20uL.

[0036] (2) Hydrolysis preparation of samples:

[0037] (2.1) Accurately weigh 1.027g of uniformly mixed pure milk into a hydrolysis tube, add 10-15ml of HCl with a concentration of 6mol / l, mix the sample with a vortex mixer to dissolve it, and freeze it in liquid nitrogen or dry ice for 3 ~5min, then vacuum t...

Embodiment 2

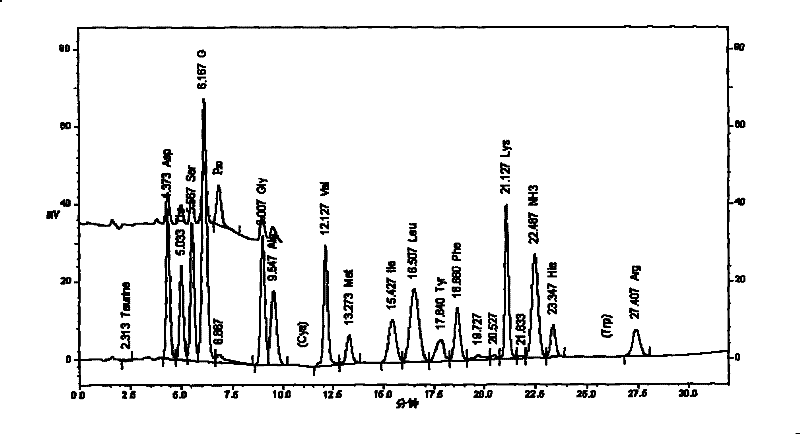

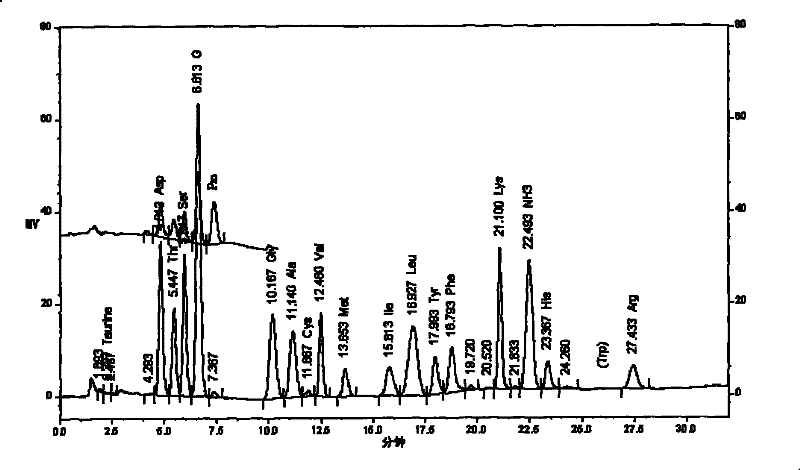

[0066] Example 2 Detection of the content of 17 kinds of amino acids in milk powder and the recovery experiment.

[0067] 1. Detection of 17 kinds of amino acids in different milk powders:

[0068] (1) Prepare amino acid mixed standard solution.

[0069] Take amino acid mixed standard solution 0.4ml (produced by Ajinomoto Co., Ltd. in Japan, various amino acid mixed standard solution in 0.1mol / L HCl solution, its concentration is 2.50 μ mol / ml, wherein proline is 5.0 μ mol / ml), use Dissolve 0.02mol / L hydrochloric acid solution and dilute to 10ml to prepare 2nmol / 20uL amino acid mixed standard working solution, in which proline is 4nmol / 20uL.

[0070] (2) Hydrolysis preparation of samples:

[0071] (2.1) Accurately weigh 0.0302g of uniform whole milk powder and 0.0508g of infant formula milk powder into hydrolysis tubes, add 10-15ml of HCl with a concentration of 6mol / l, mix the samples with a vortex mixer to dissolve them, and place Freeze in liquid nitrogen or dry ice for ...

Embodiment 3

[0101] Embodiment 3 Traditional standard addition recovery rate comparative experiment

[0102] Add different amounts of amino acid mixed standard solution (identical to the amino acid mixed standard solution used in Example 1) to the milk sample containing known amino acids respectively, so that the amino acid content added in the milk sample is respectively 0.1n mol / ul, 0.2 Three gradients of n mol / ul and 1n mol / ul (the content of proline is doubled), the content of amino acid was determined after the sample was hydrolyzed according to the method of Example 1, each sample was measured in parallel 5 times, and the recovery rate was calculated:

[0103] Recovery rate=(measured value after adding mixed standard solution-measured value of sample) / theoretical value of mixed standard solution.

[0104] The result is as follows:

[0105] various

amino acid

Add 0.1n.mol / ul standard solution

(Recovery rate%)

Add 0.2n.mol / ul standard solution

(Recov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com